Soft and hard combined plate lamination method

A soft-rigid combination board and hard board technology, applied in the direction of assembling printed circuits with electrical components, can solve the problems of long process, voids between layers, difficult to grasp the thickness difference range, etc., to achieve high production efficiency, short process, improved layer effect of inter-reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

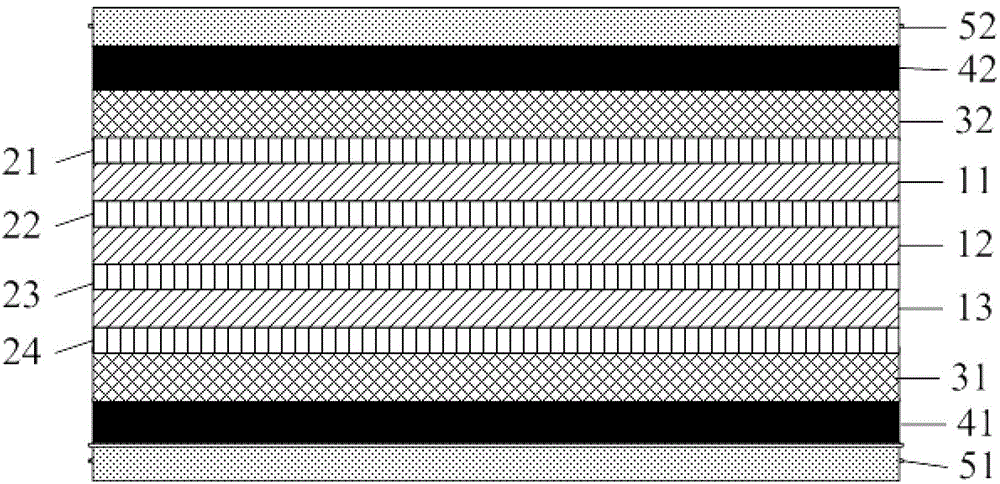

[0034] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

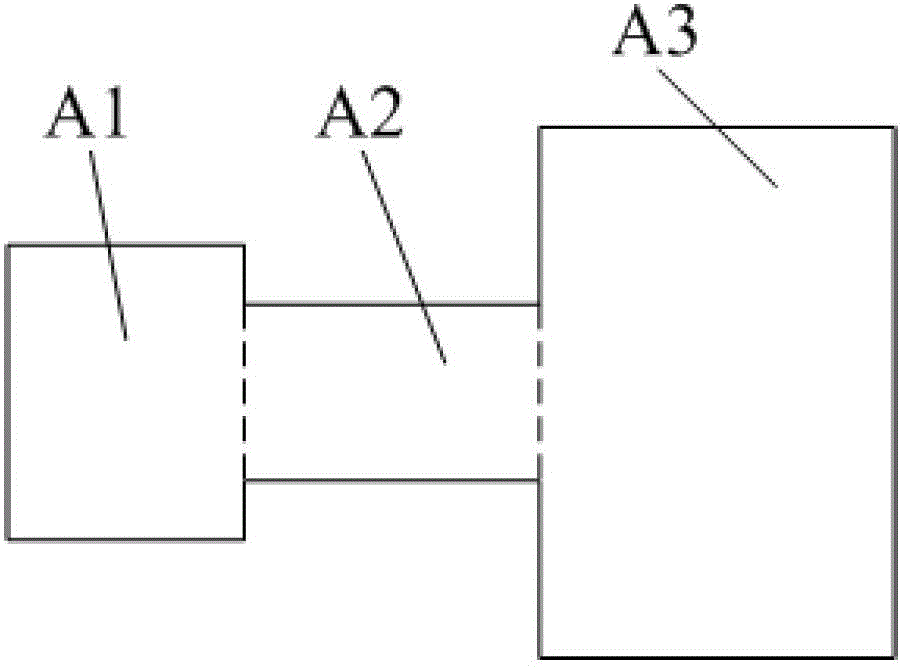

[0035] In the pressing method of the soft-rigid combination board according to the embodiment of the present invention, a companion board is placed on the thinner plate area to keep the overall plate thickness as consistent as possible, so that the problem of pressure loss in the thin plate area and the problem of pressure loss in the thick plate area can be solved in one press. Abnormal glue flow problem.

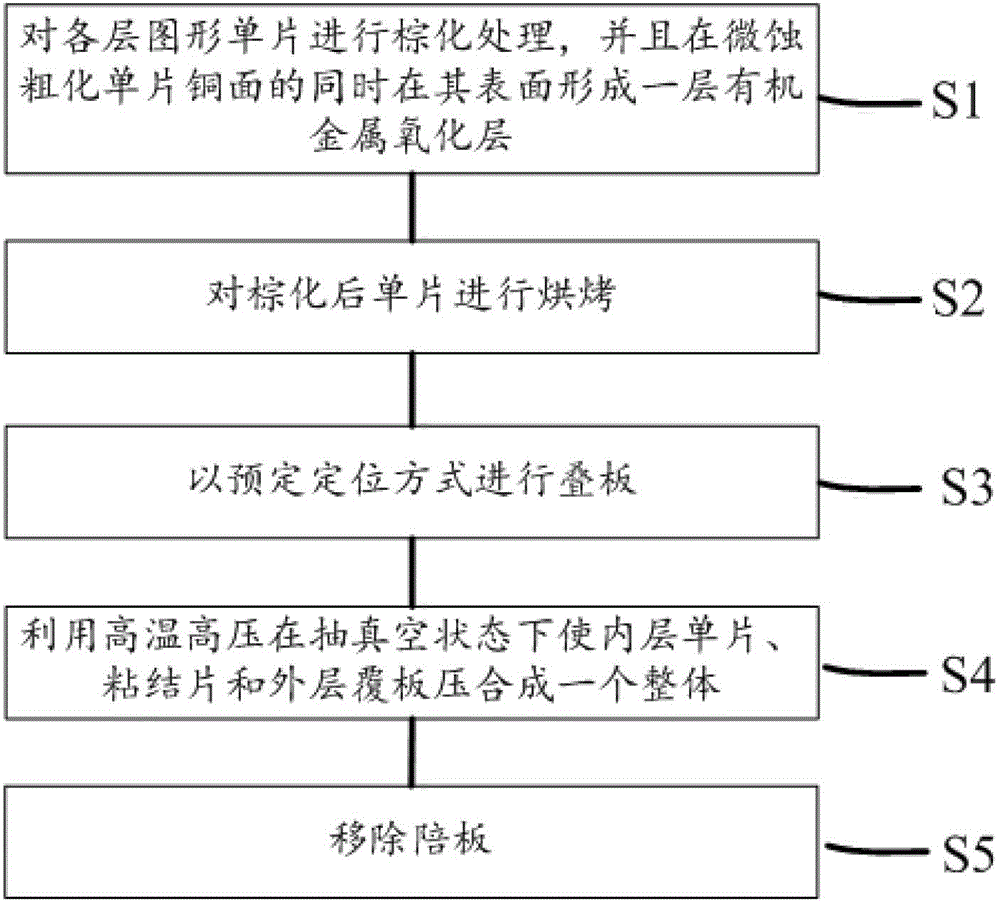

[0036] Specifically, image 3 A flow chart of a method for pressing a rigid-flex board according to an embodiment of the present invention is shown. Such as image 3 As shown, according to the embodiment of the present invention, the pressing method of the rigid-flex board may include:

[0037] The first step S1: Carry out browning treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com