Novel focal plane array electrical interconnection process

A focal plane array and electrical interconnection technology, applied in circuits, electrical components, electrical solid devices, etc., can solve problems such as increased thermal conductivity and deformation of indium columns, and achieve the effects of improving performance and avoiding increased thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

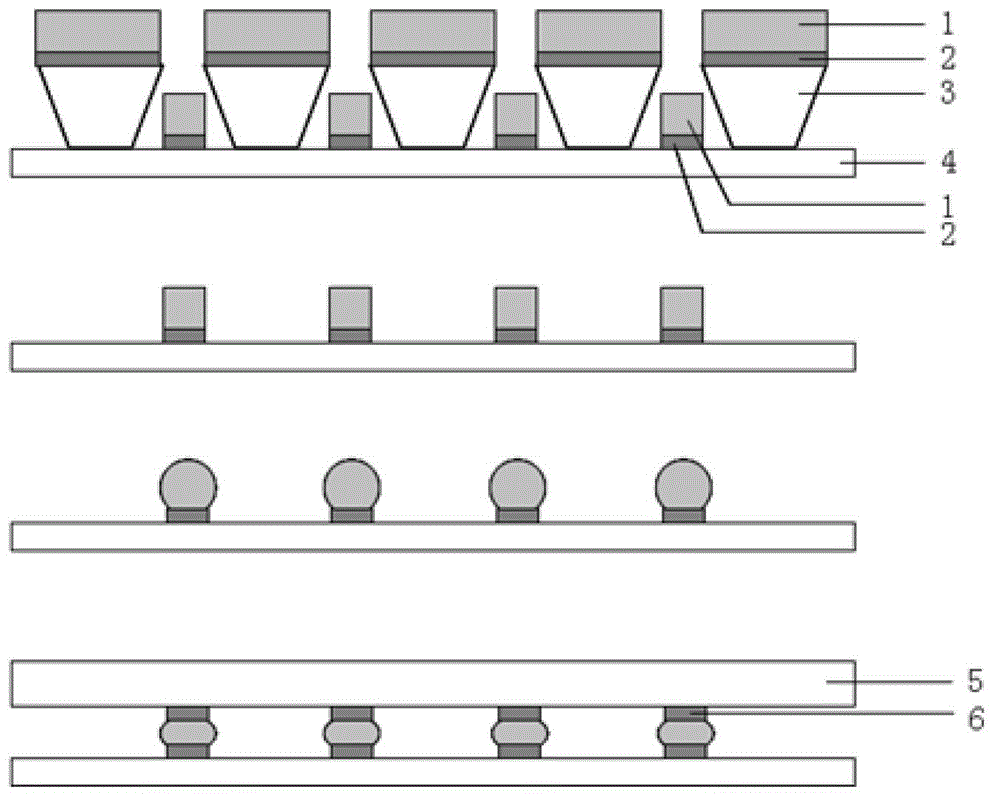

[0021] Such as figure 2 As shown, the present invention is a novel focal plane array electrical interconnection process.

[0022] First, the photolithography process on the readout circuit is carried out. This process is exposed through an ultraviolet mask to form a pattern on the photoresist 3 . The thickness of the photoresist 3 should be greater than or equal to the thickness of the deposited metal film, and the inclination angle between the side wall of the pattern and the surface of the readout circuit 4 should be less than or equal to 90°, that is, the pattern is an inverted trapezoid or rectangle, so as to facilitate the formation of the photoresist after coating. 3 strips.

[0023] Next is the deposition of the metal film. There are many methods that can be used in this process, such as electron beam evaporation, magnetron sputtering and so on. He...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com