Plasma processing system with airflow limiting mechanism and method using same

A plasma and gas flow confinement technology, applied in the direction of plasma, electrical components, discharge tubes, etc., can solve the problems of reduced plasma processing efficiency, uneven distribution of gas, uneven plasma gas, etc., to achieve uniform plasma processing, Increase uniformity, increase the effect of process uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention are described in detail below:

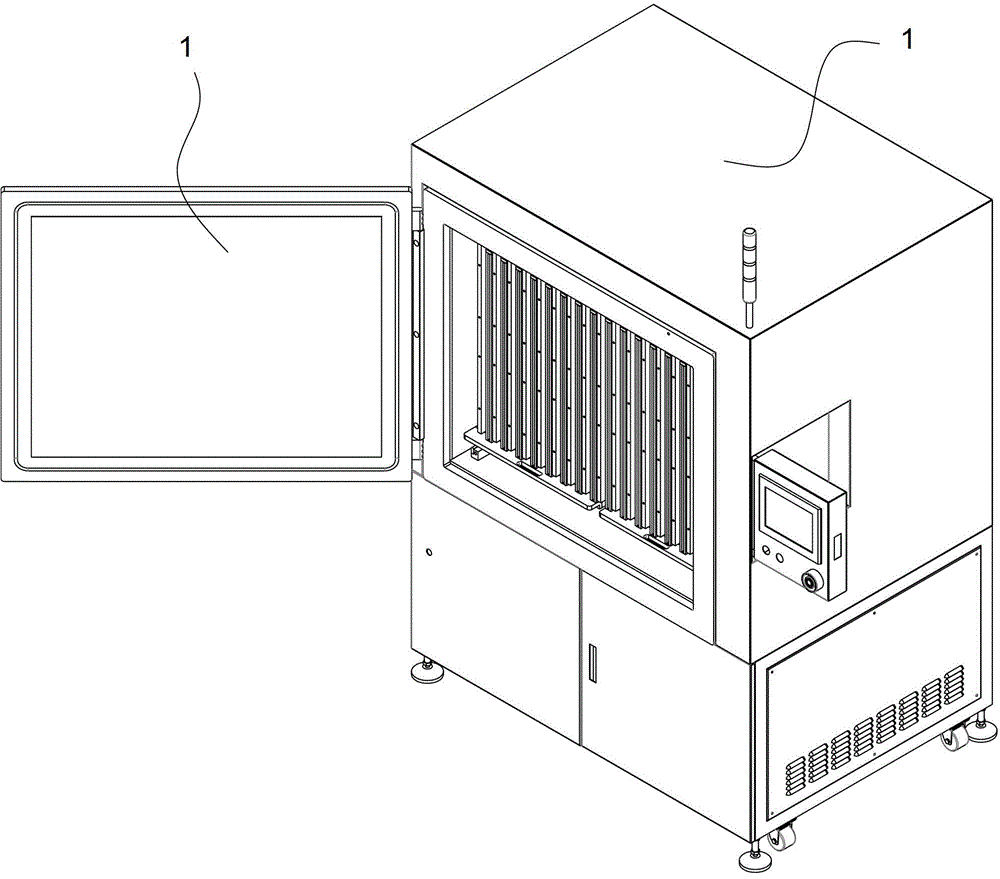

[0033] Such as Figure 1-2 As shown, a plasma processing system includes an outer frame 1, an electrode plate 2, a gas delivery pipeline 3, a vacuum system 6, and a material placement fixture 4; the electrode plate 2, the material placement fixture 4, and the gas delivery pipeline 3 are The provided air outlets are all located in the vacuum cavity 5 formed by the outer frame 1; Figure 4-5 As shown, the material placement fixture 4 is a frame structure, which is a product holder made of four solid metal materials, located between two corresponding electrode plates 2, and the gas delivery pipeline 3 is located between the material placement fixture 4 and Between the electrode plates 2, the air outlet is directly opposite to the frame 41 of the material placing fixture.

[0034] The vent hole is circular with a diameter of 1-2mm. The electrode area is 0.3-1.5 square meters, preferably 0.7 square mete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com