Method for determining organic sulfur in hydrodesulfurization reaction products

A technology of hydrodesulfurization and reaction products, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as environmental pollution, and achieve the effects of strong operability, stable operation, and reduced analysis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

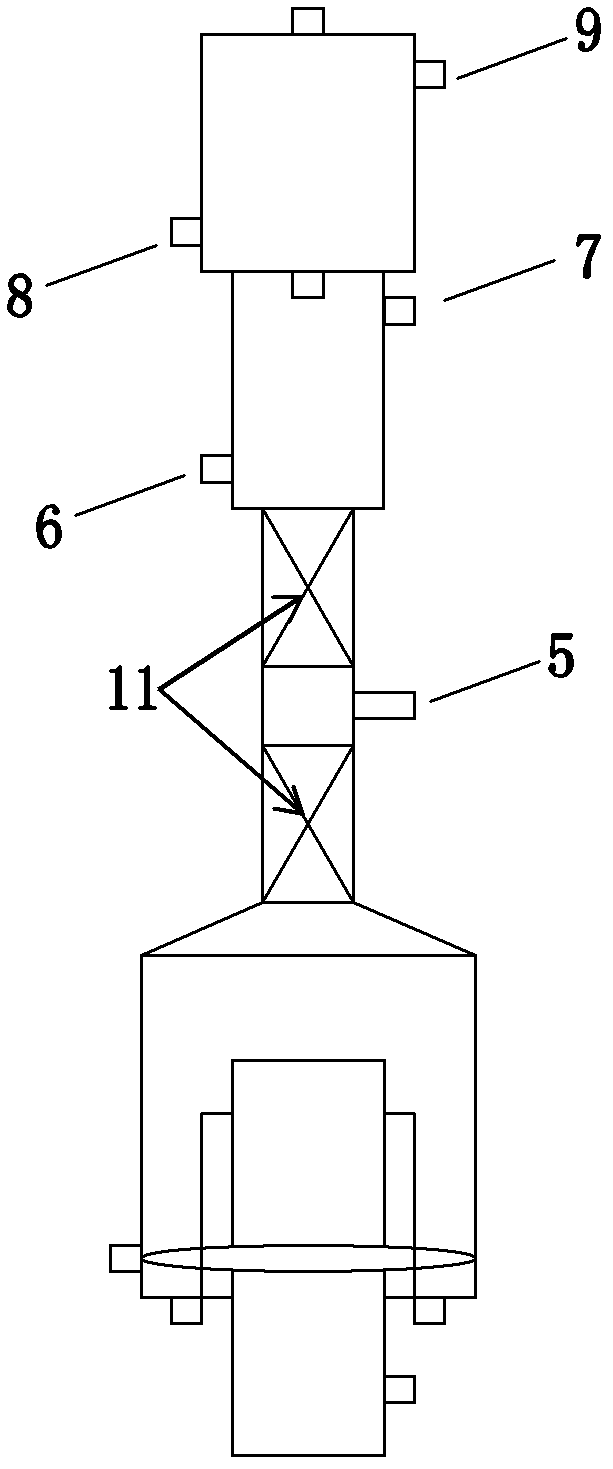

[0024]From top to bottom, it includes reflux section A, rectification section B, stripping section C and tower still D; tower still D is equipped with inert gas inlet 1, liquid discharge port 2, desulfurized product outlet 3 and liquid level control 12. The inlet 5 of the desulfurization liquid entering the stabilization tower is located between the stripping section C and the rectifying section B, and the inside of the stripping section C and the rectifying section B is equipped with packing 11; Inlet 8, condensate outlet 9 and non-condensable gas outlet 10; the entire stabilizing tower has a heating layer or insulation layer outside. The inert gas inlet 1 is located at the lower part of the tower kettle D, the liquid discharge port 2 is located at the bottom of the tower kettle D, the desulfurized product outlet 3 is located at the bottom of the liquid level controller 12, and the temperature control thermocouple 4 goes deep into the tower kettle from the lower part of the to...

Embodiment 2

[0028] The dehydrogen sulfide stabilization tower is adopted, and the gas feed position entering the stabilization tower is in the extraction and retention section, with 6 heating control points inside and 3 heating control points outside, respectively controlling the feed temperature of the liquid raw material, the temperature of the rectification section, and the stripping section. The temperature of section, tower kettle and tower top reflux; the packing of the stabilizing tower is a stainless steel Raschig ring with a diameter of 15mm. Other structures and settings of the stabilizing tower are the same as in Example 1, the temperature of the tower bottom is controlled at 180° C., the liquid fraction is kerosene, and other working conditions are the same as in Example 1. The sulfur content data of the product after desulfurization are shown in Table 1.

Embodiment 3

[0030] Adopt the dehydrogen sulfide stabilizing tower of embodiment 1, interior has 2 heating control points; The outside has 1 heating control point, respectively controls the liquid rectifying section stripping section temperature, the temperature of tower kettle, tower top reflux; The filler is a ceramic ring with a diameter of 3mm. The liquid fraction is diesel oil, and other structures and settings of the stabilizing tower are the same as those in Example 1. See Table 1 for the working conditions and the sulfur content of the product after desulfurization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com