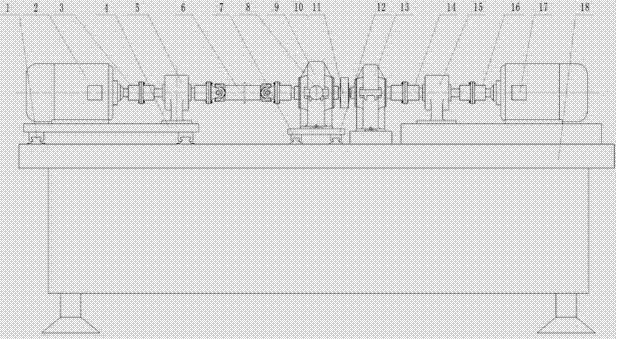

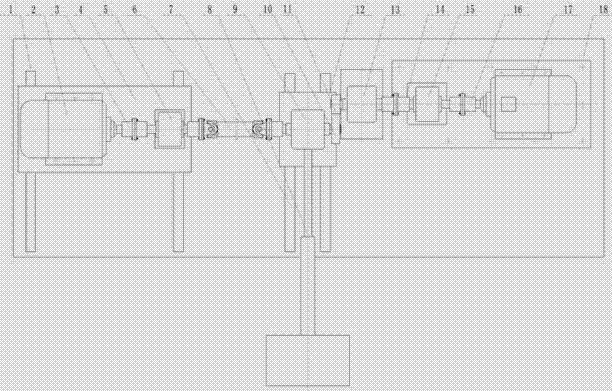

Online detection tester for rotary drive pair mechanism

A technology of transmission pair and experimental machine, which is applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problem of single function and achieve the effect of convenient and fast change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] During specific implementation, an on-line detection test machine for a rotating transmission pair mechanism includes: a first guide rail 1, a first drive motor 2, a first rigid coupling 3, a first support plate 4, a first torque sensor 5, and a first torque sensor 5. To the coupling 6, the second guide rail 7, the loading electric cylinder 8, the first headstock 9, the second support plate 12, the second headstock 13, the second rigid coupling 14, the second torque sensor 15, the third Rigid shaft coupling 16, the second drive motor 17 and support 18 and acceleration sensor, temperature sensor, displacement sensor and pressure sensor; Wherein, described first guide rail and second guide rail are arranged on support 18 in parallel; Said The first drive motor 2 and the first torque sensor 5 are connected through the first rigid coupling 3, and both are fixed together on the first support plate 4, and the first support plate 4 is slidably arranged on the first guide rail 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com