Flat plate collector with heat pipes

A flat-plate collector and heat pipe technology, which is applied to solar collectors, solar collectors using working fluids, heating devices, etc., can solve the problems of easy freezing and cracking of collector pipes, easy falling off, and high price. , to avoid the problem of firmness and thermal resistance of laser welding or ultrasonic welding, improve heat transfer effect, and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

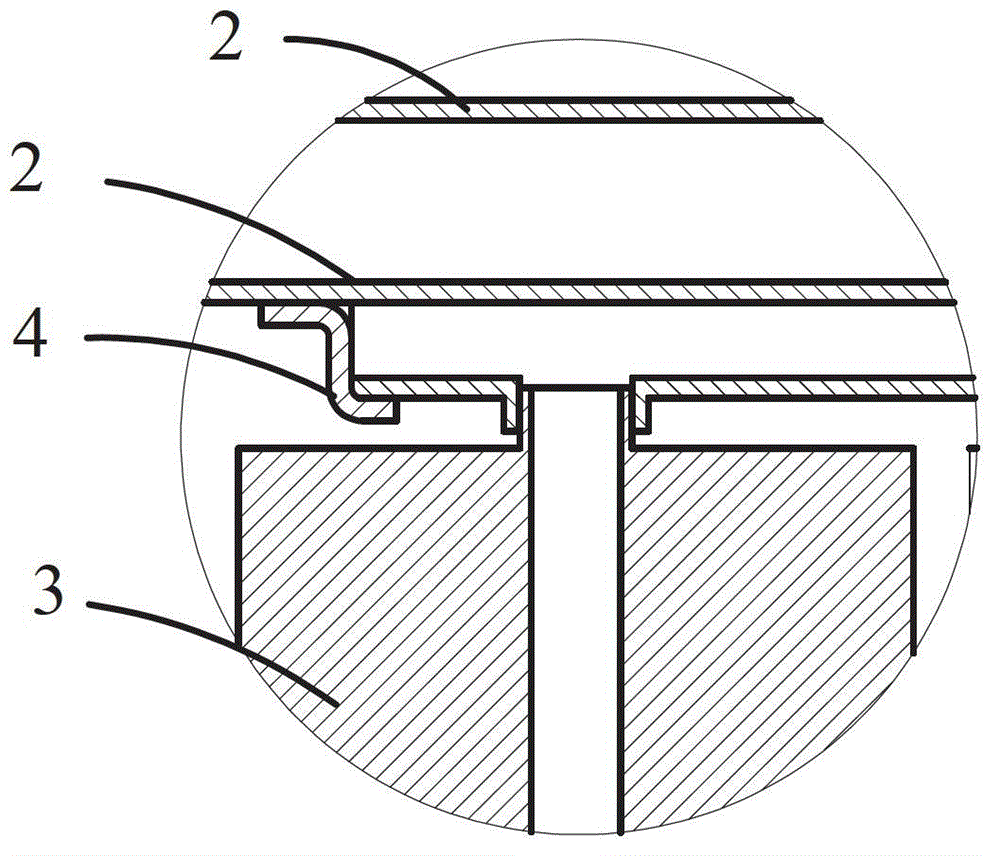

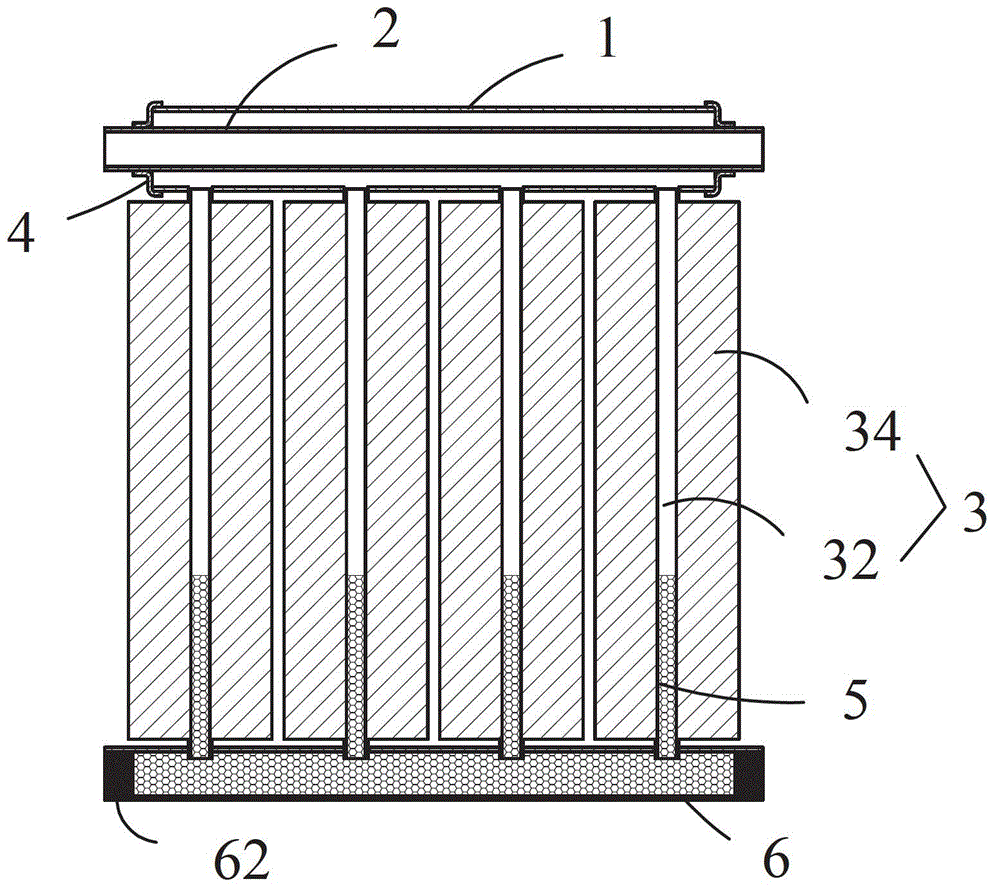

[0025] The heat pipe flat plate heat collector of the present invention includes an outer frame, high light-transmitting tempered glass is inlaid on the outer frame, and a heat-absorbing plate core is installed under the tempered glass, please refer to the same time figure 1 and figure 2 As shown, the heat absorbing plate core includes an upper communication header 1 , a heat exchange tube 2 and a heat collection tube 3 . The heat collecting tube 3 includes a heat collecting flow channel 32 and heat collecting fins 34 arranged on both sides of the heat collecting flow channel 32 .

[0026] The heat exchange tube 2 is arranged inside the upper communication header 1, and the tail end and the head end of the heat exchange tube 2 extend out of the upper communication header 1, and the two ends of the upper communication header 1 are sealed with the heat exchange tube 2, as In an optional solution, the upper communication header 1 and the heat exchange tube 2 are welded through ...

no. 2 example

[0030] see image 3 As shown, the difference between this embodiment and the above-mentioned first embodiment is that the heat pipe flat collector further includes a lower communication header 6 , and both ends of the lower communication header 6 are sealed with sealing plugs 62 .

[0031] In the above two embodiments, the heat collecting tube 3 is formed by one-time extrusion, that is, the heat collecting runner 32 and the heat collecting fins 34 are integrally formed. Compared with the use of copper, the production cost is reduced.

[0032] The heat collecting fins 34 of adjacent heat collecting tubes 3 can be separated by a small distance, such as figure 1 and image 3 As shown in , it is also possible to overlap each other, as in Figure 4 shown in .

[0033] And the structure of heat collecting tube 3 can have many kinds, as Figures 5 to 12 shown.

[0034] Figure 5 The heat collecting runner 32 of the shown heat collecting tube 3 is a cylindrical hollow structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com