Construction machinery control method and construction machinery

A technology of construction machinery and control methods, which is applied in the direction of engine control, pump control, mechanical equipment, etc., can solve the problems of unable to meet power requirements and energy saving, and achieve the effect of simple implementation and low transformation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

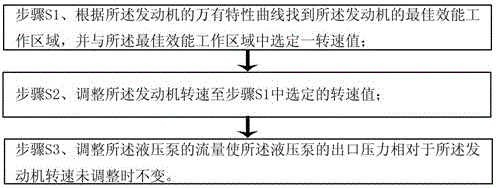

[0019] Such as figure 1 As shown, an embodiment of a control method for engineering machinery in the present invention includes an engine and a hydraulic system for driving the actuator of the engineering machinery. The hydraulic system includes a hydraulic pump. The specific steps are as follows:

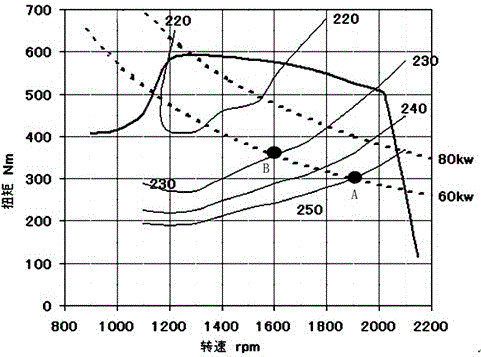

[0020] Step S1, find the best efficiency working area of the engine according to the universal characteristic curve of the engine, and select a rotational speed value in the best efficiency working area;

[0021] Step S2, adjusting the engine speed to the speed value selected in step S1;

[0022] Step S3 , adjusting the flow rate of the hydraulic pump so that the outlet pressure of the hydraulic pump remains unchanged when the engine speed is not adjusted.

[0023] The working principle of the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com