Disassembly-free cleaning agent for fuel spray nozzle

A technology for cleaning agents and fuel injectors, applied in detergent compositions, non-surface-active detergent compositions, organic non-surface-active detergent compositions, etc., which can solve deformation, swelling, insufficient combustion, corrosion and discoloration of metal parts and other problems, to achieve the effect of small molecular weight, speed up the dissolution rate, and increase the oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Under normal temperature and pressure, weigh 400g of No. 200# solvent oil, then add 25g of n-propylamine, 15g of isopropanol, and 60g of ethyl acetate to obtain a mixture, stir evenly, and obtain 500g of the fuel injection nozzle of the present invention without dismantling Cleaning agent, based on the overall mass of the cleaning agent as 100%, wherein the components and their mass percentages are as follows: 5% carbon remover, 3% accelerator, 12% combustion aid, and 80% diluent.

[0026] The cleaning efficiency of described cleaning agent, the corrosion performance of copper sheet and the impact on rubber and plastics are tested as follows:

[0027] (1) Cleaning efficiency test

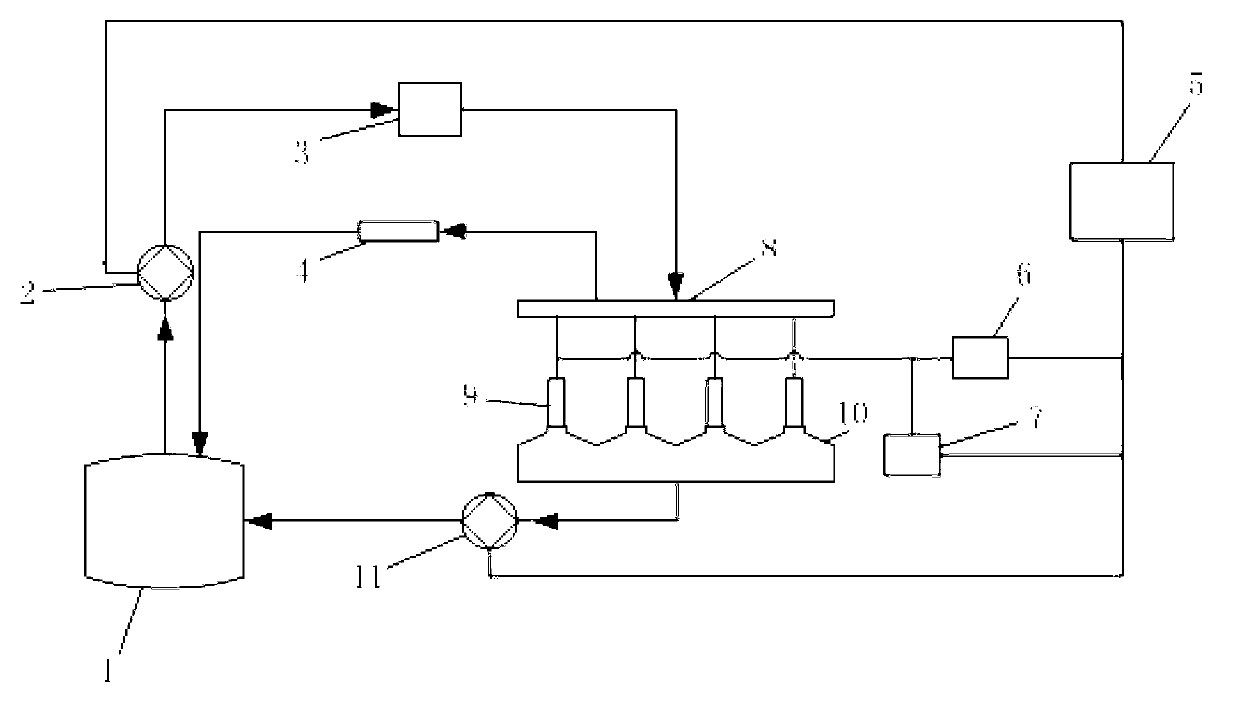

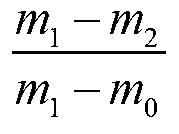

[0028] The cleaning efficiency test uses simulated carbon deposit cleaning effect evaluation, figure 1 It is a schematic diagram of the carbon deposition simulation device. In the simulation device, the fuel tank 1 is connected to the first oil pump 2, the first oil pump 2 is connected to t...

Embodiment 2

[0039] Under normal temperature and pressure, weigh 300g of kerosene, add 50g of n-butylamine, 10g of N-methylpyrrolidone, 15g of ethylene glycol monobutyl ether, and 125g of diacetone alcohol to obtain a mixture, stir evenly, and obtain 500g of the present invention. The fuel injection nozzle disassembly-free cleaning agent described above, based on the total mass of the cleaning agent as 100%, wherein the components and their mass percentages are as follows: 10% for the carbon remover, 5% for the accelerator, and 25% for the combustion aid , the diluent is 60%.

[0040] The performance test is carried out to the prepared cleaning agent, and the test method refers to the test method in Example 1. Test results: The cleaning efficiency is 52%, the corrosion level of copper sheet is 0, and it has no effect on plastic and rubber.

Embodiment 3

[0042] Under normal temperature and pressure, weigh 260g of kerosene, 70g of gasoline, add 80g of triethylamine, 40g of N-methylpyrrolidone, 30g of ethanol, and 20g of dimethyl carbonate to obtain a mixture, stir evenly, and obtain 500g of the present invention. No-disassembly cleaning agent for fuel injectors, based on 100% of the total mass of the cleaning agent, the components and their mass percentages are as follows: 16% for the carbon remover, 8% for the accelerator, and 10% for the combustion aid. Thinner is 66%.

[0043] The performance test is carried out to the prepared cleaning agent, and the test method refers to the test method in Example 1. Test results: The cleaning efficiency is 77%, the corrosion level of copper sheet is 0, and it has no effect on rubber and plastic.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com