Polyurethane adhesive for trenchless repairing of pipelines and preparation method for polyurethane adhesive

A polyurethane adhesive and pipeline repair technology, which is applied in the directions of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., to achieve the effects of satisfying construction time, low cost of raw materials, and simple and easy synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: the preparation method of polyurethane prepolymer:

[0034] At a temperature of 80°C, add 43g of polyether N220 and 32g of polycarbonate diol (calculated based on a molecular weight of 2000), and heat up to 130°C for 2 hours after they are completely melted (vacuum degree reaches 0.09MPa) . Then cool down the system to 75°C, add 212g of crude MDI, then raise the temperature to 80°C, react at constant temperature for 2.5 hours, and vacuumize for 0.5 hours after the reaction to obtain a prepolymer. After testing, the mass percentage of the isocyanate of the obtained prepolymer was 19.8%.

Embodiment 2

[0035] Embodiment 2: the preparation method of polyurethane prepolymer:

[0036] At a temperature of 80°C, add 64.0g of polyether N220 and 42.0g of polycarbonate diol (calculated with a molecular weight of 2000), and heat up to 135°C to vacuum for 2 hours after they are completely melted (vacuum degree reaches 0.09MPa) ). Then cool down the system to 75°C, add 275.0g of crude MDI, then raise the temperature to 80°C, and react at constant temperature for 2.5 hours. After the reaction, vacuumize for 1 hour to obtain a prepolymer. After testing, the mass percent of isocyanate in the obtained prepolymer was 20.6%.

Embodiment 3

[0037] Embodiment 3: a kind of preparation method of polyurethane adhesive for non-excavation pipeline repair:

[0038] Synthetic curing agent:

[0039] First weigh 1.15g of KH-570 silane coupling agent, hydrolyze it in 95% ethanol solution with a pH value of 4.00 for 45min until clarification, and obtain the hydrolyzate of silane coupling agent; add 0.5 g hexadecyl to 500 mL water Trimethylammonium bromide, fully emulsified, then add the hydrolyzate, stir and mix evenly, heat to 80°C, add 100 g of kaolin, stir on a stirrer at a speed of 180 rpm for 150 minutes, suction filter, and dry; 2.21 g of the modified inorganic filler and 55.15 g of polycarbonate diol were stirred for 15 min at 40° C. at a speed of 200 rpm, and then discharged.

[0040] Synthetic polyurethane prepolymer:

[0041] Add 67.1g polyether (calculated as N220) and 49.2g polycarbonate diol (calculated as molecular weight 2000) at 80°C, heat up to 130°C and vacuumize for 2.5 hours after all melted, so that the ...

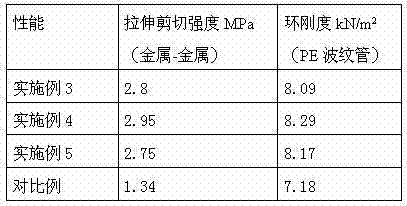

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com