Low-pressure-variation ethylene-propylene rubber mixed compound and mixing method

A technology for ethylene-propylene rubber raw rubber and ethylene-propylene rubber, which is applied in the field of rubber mixing and mixing, can solve the problems of large pressure change and cannot fully meet the requirements of working conditions, and achieves low pressure change and meets the requirements of working conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

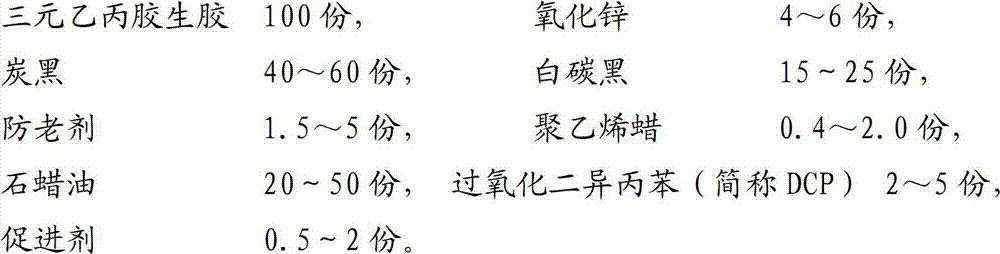

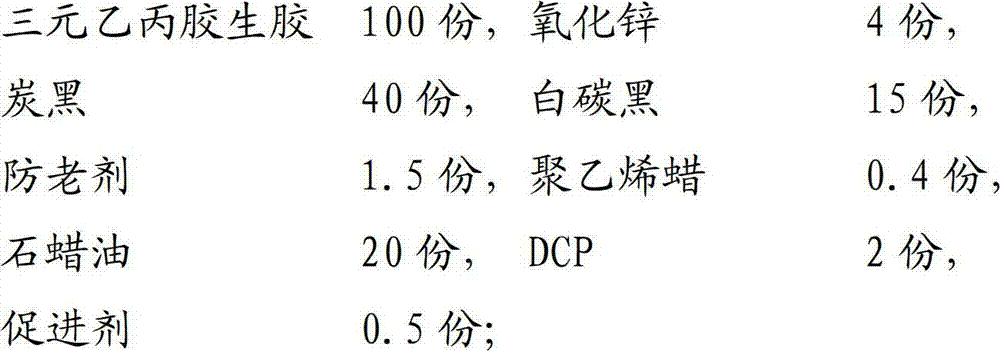

[0024] A low-pressure variable ethylene-propylene rubber compound comprising the following raw materials in parts by weight:

[0025]

[0026] The anti-aging agent is anti-aging agent AW;

[0027] The accelerator is the accelerator TAIC.

[0028] The mixing method of above-mentioned a kind of low pressure variable ethylene propylene rubber compounded rubber, comprises the steps:

[0029] 1) Put 100 parts of EPDM raw rubber into the kneader for mastication;

[0030] 2) Put 4 parts of zinc oxide, 40 parts of carbon black, 15 parts of white carbon black, 1.5 parts of antioxidant and 0.4 parts of polyethylene wax into the kneader and knead for 3 minutes;

[0031] 3) Put 20 parts of paraffin oil into the kneader;

[0032] 4) When the temperature of the kneader reaches ≤135°C, discharge the rubber material, and cool down in the lower part of the open mill;

[0033] 5) After the rubber material is cooled and parked, put the rubber material into the kneader, add 2 parts of DCP ...

Embodiment 2

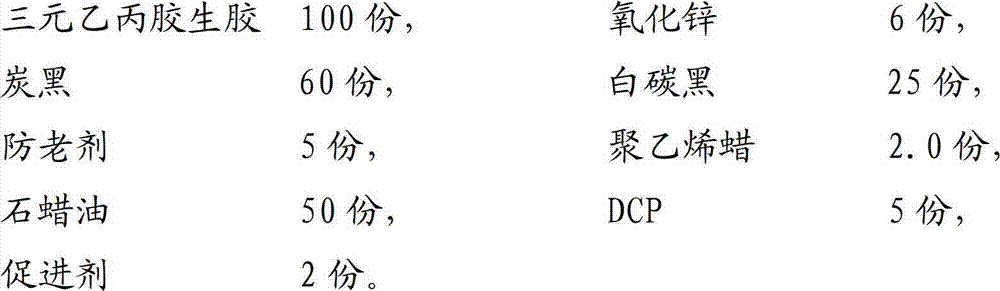

[0036] A low-pressure variable ethylene-propylene rubber compound comprising the following raw materials in parts by weight:

[0037]

[0038] The anti-aging agent is anti-aging agent RD.

[0039] The accelerator is the co-bridging agent TRIM / S.

[0040] The mixing method of above-mentioned a kind of low pressure variable ethylene propylene rubber compounded rubber, comprises the steps:

[0041] 1) Put 100 parts of EPDM raw rubber into the kneader for mastication;

[0042] 2) Put 5 parts of zinc oxide, 60 parts of carbon black, 25 parts of white carbon black, 5 parts of anti-aging agent, 2 parts of polyethylene wax into the kneader and knead for 5 minutes;

[0043] 3) Put 50 parts of paraffin oil into the kneader;

[0044] 4) When the temperature of the kneader reaches ≤135 degrees, discharge the rubber material, and cool down in the lower part of the mill;

[0045] 5) After the rubber material is cooled and parked, put the rubber material into the kneader, add 5 parts ...

Embodiment 3

[0048] A low-pressure variable ethylene-propylene rubber compound comprising the following raw materials in parts by weight:

[0049]

[0050] The anti-aging agent is anti-aging agent 4010;

[0051] The accelerator is the accelerator TAIC.

[0052] The mixing method of above-mentioned a kind of low pressure variable ethylene propylene rubber compounded rubber, comprises the steps:

[0053] 1) Put 100 parts of EPDM raw rubber into the kneader for mastication;

[0054] 2) Put 5 parts of zinc oxide, 45 parts of carbon black, 15 parts of white carbon black, 2 parts of antioxidant and 3 parts of polyethylene wax into the kneader and knead for 5 minutes;

[0055] 3) Put 30 parts of paraffin oil into the kneader;

[0056] 4) When the temperature of the kneader reaches ≤135 degrees, discharge the rubber material, and cool down in the lower part of the mill;

[0057] 5) After the rubber material is cooled and parked, put the rubber material into the kneader, add 3.3 parts of DCP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com