Polyamide modified polyester resin and preparation method thereof, and automotive primer surfacer containing polyester resin

A technology of polyester resin and modified polyester, which is applied in the field of automotive paint, can solve the problems of poor stone chip resistance and inability to store for a long time, and achieve enhanced stone chip resistance, enhanced strength and toughness, and excellent mechanical properties. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also provides the preparation method of this polyester resin, and this method comprises the following steps:

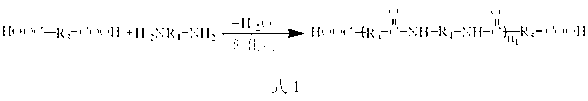

[0032] S1 In the presence of a catalyst and under the protection of nitrogen, the diamine and excess dibasic acid are subjected to polyamidation reaction to obtain a carboxyl-terminated polyamide polymer;

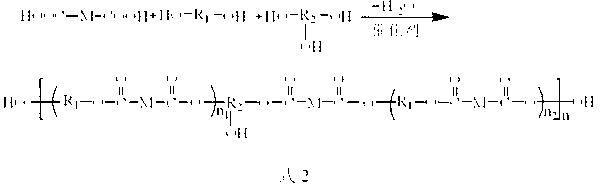

[0033] S2 Then add diol and triol to the polyamide polymer for esterification reaction to synthesize polyester resin.

[0034] According to the preparation method provided by the present invention, polyamidation reaction is carried out by diamine and excess dibasic acid, and a carboxyl-terminated polyamide oligomer intermediate with small molecular weight is synthesized. The specific reaction is as formula 1. Then, adding dibasic alcohol and tribasic alcohol to the polyamide oligomer intermediate to carry out esterification reaction, and synthesizing a saturated polyester resin modified by polyamide with terminal hydroxyl groups. The ...

Embodiment 1

[0055] This example is used to illustrate a polyester resin for polyamide-modified coating and its preparation method provided by the present invention.

[0056] In a 2L three-necked flask equipped with a water separator, reflux condenser, stirrer and thermometer, add 184.64g of hexamethylenediamine, 609.9g of isophthalic acid, 32.1g of terephthalic acid, 432.375g of adipic acid and 2.45g of catalyst , under the protection of N2, slowly raise the temperature to 110°C, start to stir slowly, slowly raise the temperature to 160°C, keep warm for 1h, add heat stabilizer TP 2 2.45 g of Pi, and then the temperature was raised from 160 °C to 200 °C at a constant speed within 2 h, and kept for 1 h to obtain an intermediate of polyamide oligomer.

[0057] Under the protection of N2, lower the temperature to 140°C, add 557.9g of neopentyl glycol, 120g of trimethylolpropane, slowly raise the temperature to 160°C, keep it warm for 1h, then raise it to 210°C at a rate of 15°C / h, and vacuumi...

Embodiment 2-5

[0059] The polyester resin was prepared according to the method of Example 1, the difference being that each substance and its content are shown in Table 1 below.

[0060] Table 1

[0061] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com