Novel tridentate phosphine ligand and application of same to linear hydroformylation and similar reactions

A tridentate phosphine ligand, chemical reaction technology, applied in the preparation of carbon monoxide reaction, organic compound/hydride/coordination complex catalyst, organic chemistry, etc., can solve the problems that have not been reported in the literature of tridentate phosphine ligand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

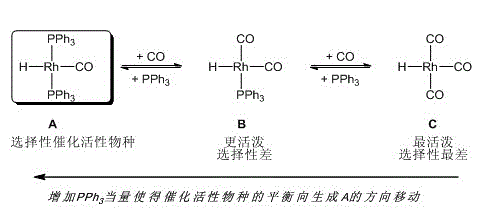

Method used

Image

Examples

Embodiment 1

[0112] Preparation of 2,2′,6-trimethoxybiphenyl (the preparation method of 2,2′,6-trimethoxybiphenyl can be found in literature: Chem.Eur.J.2003,9,3209-3215), synthesis The reaction formula is as follows:

[0113]

[0114] Add 29.9 g of m-diphenylmethyl ether into a dry 500 ml Schlenk bottle filled with nitrogen, and then add 170 mL of anhydrous tetrahydrofuran (THF) under the protection of nitrogen to obtain a mixed solution. 136 mL of 1.6 mol / L n-hexane solution of n-butyllithium was added dropwise to obtain a reaction system. After reacting for 1 h, 69 mL of a THF solution of o-bromoanisole was added dropwise to the reaction system, wherein the mass of o-bromoanisole was 18.7 g. After stirring at room temperature for 1 h, the temperature was raised to 60° C. for 12 h. After the reaction, the reaction system was cooled to room temperature, quenched by adding 200mL of water, the organic phase was separated, the aqueous phase was extracted twice with ether, the organic pha...

Embodiment 2

[0116] The preparation of 2,2′,6-trimethoxybiphenyl, the synthesis reaction formula is as follows:

[0117]

[0118] Add 182 mg of 2,6-dimethoxyphenylboronic acid to a dry Schlenk tube, and then add 2.2 mg of Pd(OAc) to the glove phase 2 , 14.3mg of Xphos, 318.5mg of anhydrous K 3 PO 4 . After replacing the Schlenk tube with a nitrogen atmosphere, 0.5 mmol of o-bromoanisole and 3 ml of anhydrous THF were added to obtain a reaction system, and the reaction system was reacted at 60° C. for 24 h. After the reaction was finished, add 3ml of water to quench, extract 3 times with dichloromethane, combine the obtained organic phases with anhydrous sodium sulfate, dry and spin dry, use petroleum ether and ethyl acetate as eluents and go through silica gel column chromatography The product obtained was a white solid with a yield of 82%. Rf=0.2(hexane / AcOEt=10:1); 1 H NMR (300MHz, CDCl 3 ):δ=3.63(s,6H;2OCH 3 ),3.66(s,3H;OCH 3 ),6.55-6.58(d, 3 J(H,H)=8.3Hz,2H;3,5-H),6.89-7.12...

Embodiment 3

[0120] The preparation of 2,2′,6-trihydroxybiphenyl, the synthesis reaction formula is as follows:

[0121]

[0122] 2.44 g of 2,2',6-trimethoxybiphenyl was added to a dry 250 mL Schlenk bottle, and after replacing the Schlenk bottle with a nitrogen atmosphere, 100 mL of anhydrous dichloromethane was added to obtain a mixed solution. Add 4.4 mL of boron tribromide dropwise to the mixed solution at -78 °C to obtain a reaction system. The reaction system was raised to room temperature and reacted for 5 h. After the reaction was finished, the reaction system was cooled to 0°C, quenched by adding 50ml of water dropwise, the organic phase was separated and collected, the aqueous phase was extracted three times with ethyl acetate, each extraction was performed with 25mL ethyl acetate, the organic phases were combined and washed with anhydrous After drying over sodium sulfate, it was filtered and spin-dried, and the residue was separated by silica gel column chromatography with p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com