Method for preparing isocyanate by means of atomizing type gas-liquid two-phase phosgenation

A spray-type technology of isocyanate, which is applied in the field of spray-type gas-liquid two-phase phosgenation to prepare isocyanate, can solve the problems of environmental pollution, reduction of reaction yield, consumption of cooling capacity, etc., and achieve scientific and reasonable process steps and simple structure of equipment and devices , Safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

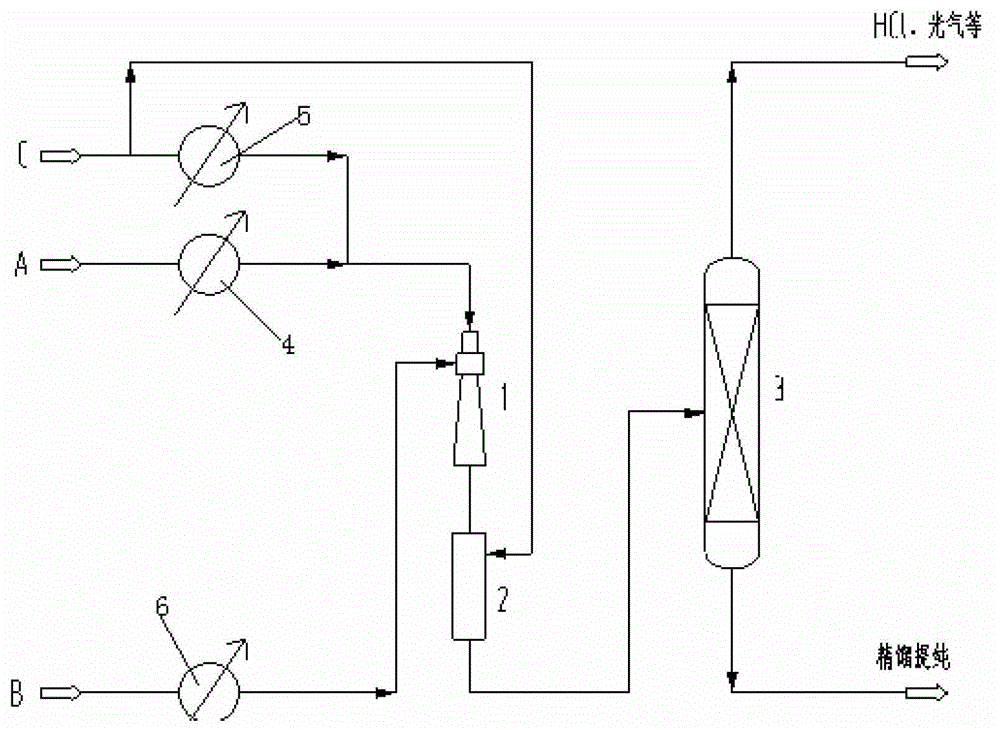

Image

Examples

Embodiment 1

[0012] In this example, the solution of toluene diamine (TDA) and chlorobenzene heated to 320°C with a molar ratio of 1:2 enters mixer 1 from the nozzle of the mixer, and the high-temperature phosgene gas heated to 380°C flows from the ejection flow of the mixer The strand enters the mixer 1, the molar ratio of phosgene and TDA entering the mixer 1 is 4:1, the pressure of the mixer 1 is 1 bar, in the mixer 1, TDA and amine are mixed and undergo a preliminary reaction, and come out of the mixer 1 After the gas enters the reactor 2 and contacts with chlorobenzene, it is quenched to 150°C and continues to react in the reactor 2 to form isocyanate. The pressure of the reactor 2 is 1 bar. After degassing, rectification and purification are carried out to obtain toluene diisocyanate (TDI).

Embodiment 2

[0014] In this example, the toluene diamine (TDA) liquid heated to 320°C with a molar ratio of 1:2 enters the mixer 1 from the nozzle of the jet stream mixer of the mixer, and the high-temperature phosgene gas heated to 380°C flows from the mixer The nozzle enters the mixer 1, the molar ratio of phosgene and TDA entering the mixer 1 is 4:1, the pressure of the mixer 1 is 1 bar, and TDA and amine are mixed in the mixer 1 and carry out preliminary reaction, from the mixer 1 The gas that comes out enters the reactor 2 and is quenched to 150°C after being contacted with chlorobenzene, and continues to react in the reactor 2 to form isocyanate. The pressure of the reactor 2 is 1 bar. After waiting for the gas, carry out rectification and purification to obtain toluene diisocyanate (TDI).

Embodiment 3

[0016] In this example, the hexamethylenediamine (HDA) and chlorobenzene solution heated to 230°C with a molar ratio of 1:1.5 enters the mixer 1 from the nozzle of the mixer, and the high-temperature phosgene gas heated to 360°C is introduced from the outlet of the mixer 1 The jet stream enters the mixer, and the molar ratio of phosgene and HDA entering the mixer 1 is 4:1, and the pressure of the mixer 1 is 1.5 bar. In the mixer 1, HDA and amine are mixed and undergo a preliminary reaction. From the mixer 1 The gas that comes out enters the reactor 2 and is quenched to 120°C after being contacted with chlorobenzene, and continues to react in the reactor 2 to form isocyanate. Gas and other gases, and then rectified and purified to obtain hexamethylene diisocyanate (HDI).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com