Method for removing pollutants from drinking water by using supported ruthenium catalyst

A ruthenium catalyst and pollutant technology, applied in molecular sieve catalysts, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve the problem that homogeneous catalysts cannot be recycled and reused, target pollutants cannot be completely mineralized, and increase operating costs and other problems, to achieve the effect of easy solid-liquid separation, increase mineralization rate, and reduce dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

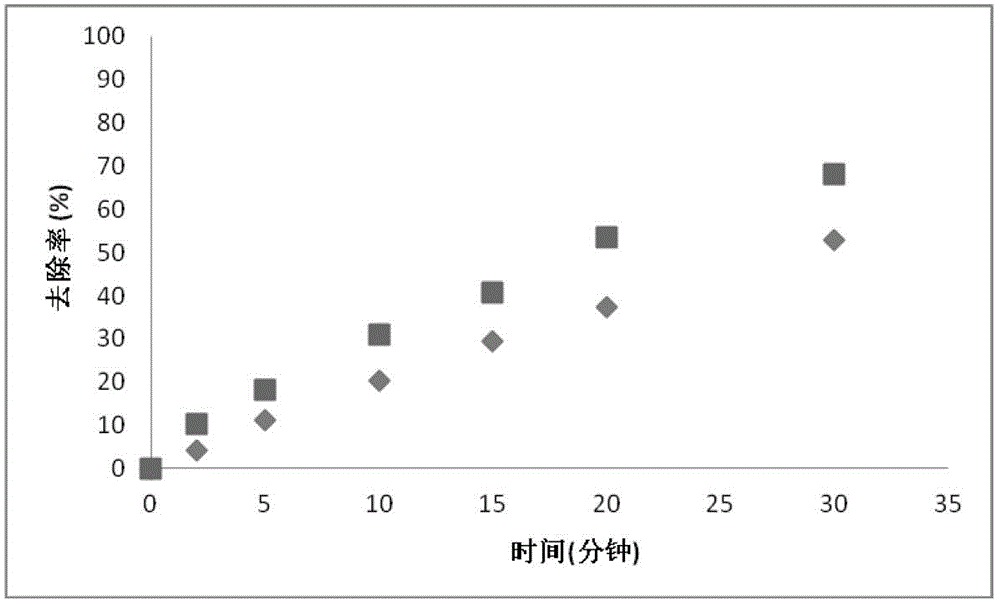

Embodiment 1

[0041] (1) Put potassium permanganate and supported ruthenium catalyst into untreated reference water at the same time, wherein the dosage of potassium permanganate is controlled at 12 mg / L, and the supported ruthenium catalyst uses activated alumina as the carrier and trichloro Ruthenium oxide is used as an effective catalytic substance, the loading amount of ruthenium is 0.5%, and the dosage is controlled at 15 mg / L (calculated as ruthenium). The reaction is carried out in a mechanically stirred flocculation tank. The mechanically stirred flocculation tank used uses a horizontal stirring shaft, and the linear speed at the center of the impeller paddle is 0.4m / s for the first row, 0.3m / s for the second row, and 0.3m / s for the last row. Use 0.2m / s. The untreated drinking water containing aniline with an initial concentration of 0.5mg / L and pH=7 is treated for 0.5h. Compared with potassium permanganate oxidation, the aniline removal rate of this embodiment method can be increas...

Embodiment 2

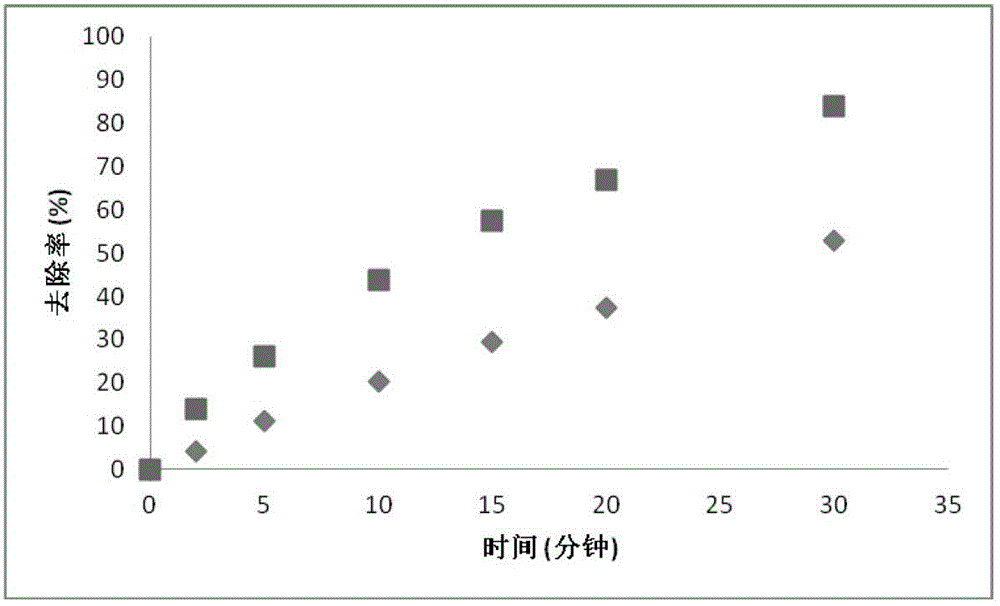

[0044] The difference between this embodiment and Example 1 is that the dosage of potassium permanganate is 2.0 mgL, the supported ruthenium catalyst uses granular ferric hydroxide as a carrier, the ruthenium load is 0.2%, and the reactor adopts a folded plate flocculation tank ( The water has been stirred while flowing) Other steps and parameters are the same as in Example 1.

[0045] The water containing aniline with an initial concentration of 0.5 mg / L and pH=7 is treated for 0.5 h. Compared with potassium permanganate oxidation, the aniline removal rate of the method in this embodiment can be increased by 35%.

Embodiment 3

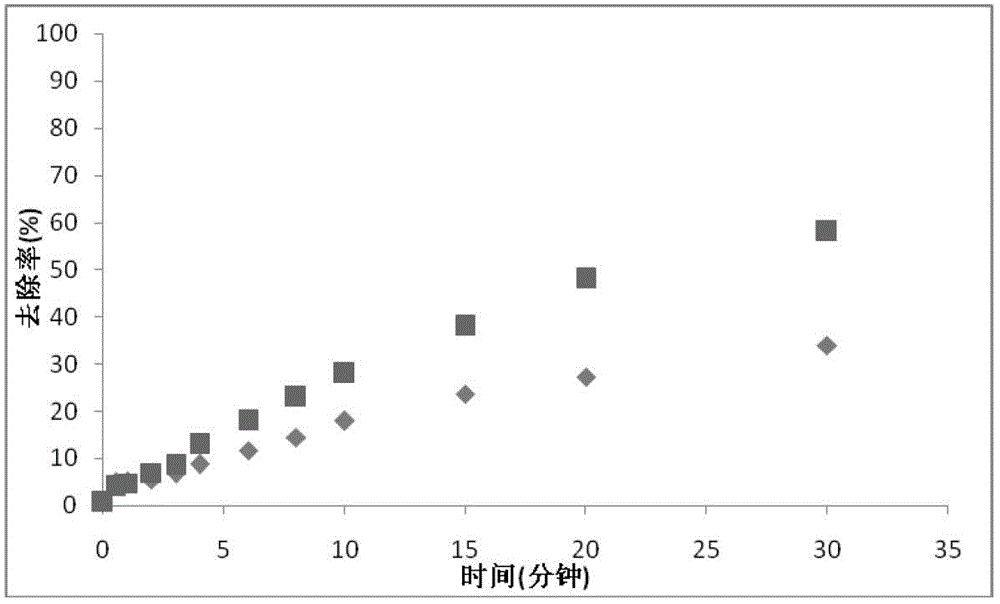

[0047] The difference between this embodiment and Example 1 is that the dosage of potassium permanganate is 3.0 mg / L, the ruthenium loading is 2%, the reactor uses a hydraulic flocculation tank, and other steps and parameters are the same as in Example 1.

[0048] The water containing aniline with an initial concentration of 0.5 mg / L and pH=7 is treated for 1 hour. Compared with potassium permanganate oxidation, the aniline removal rate of the method in this embodiment can be increased by 55%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com