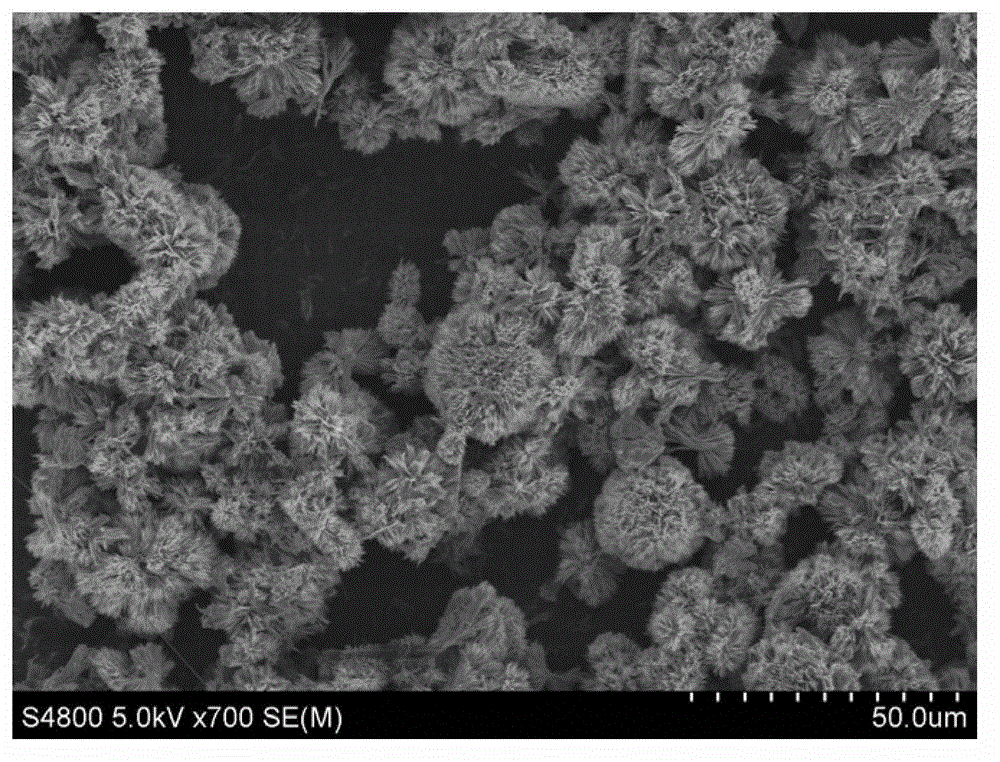

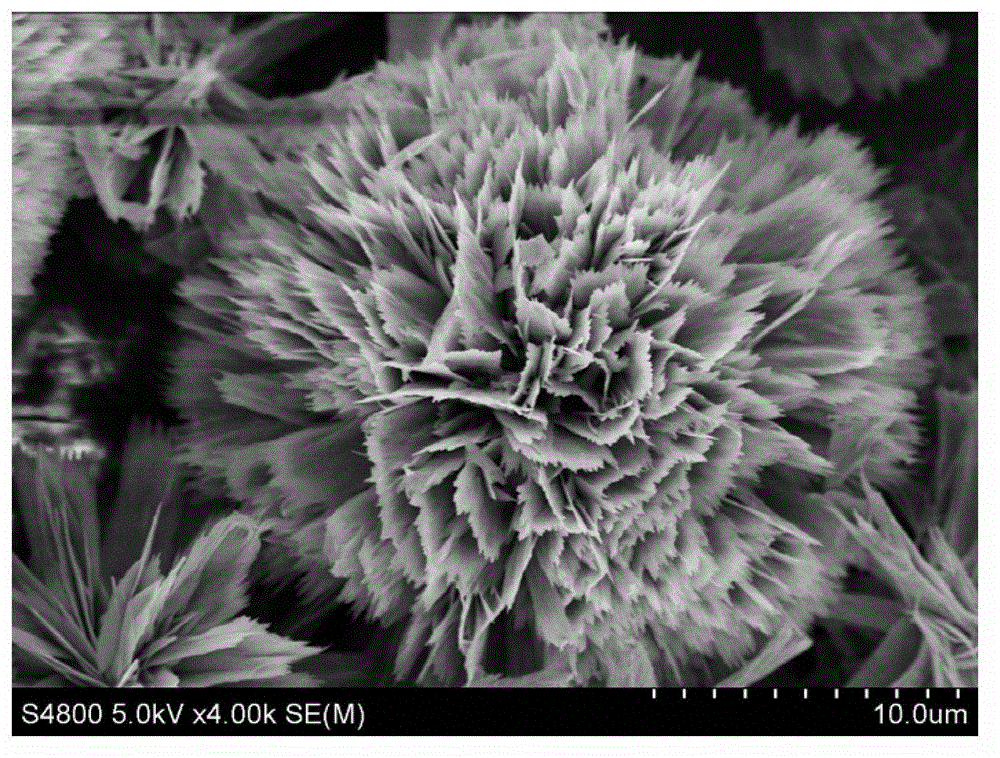

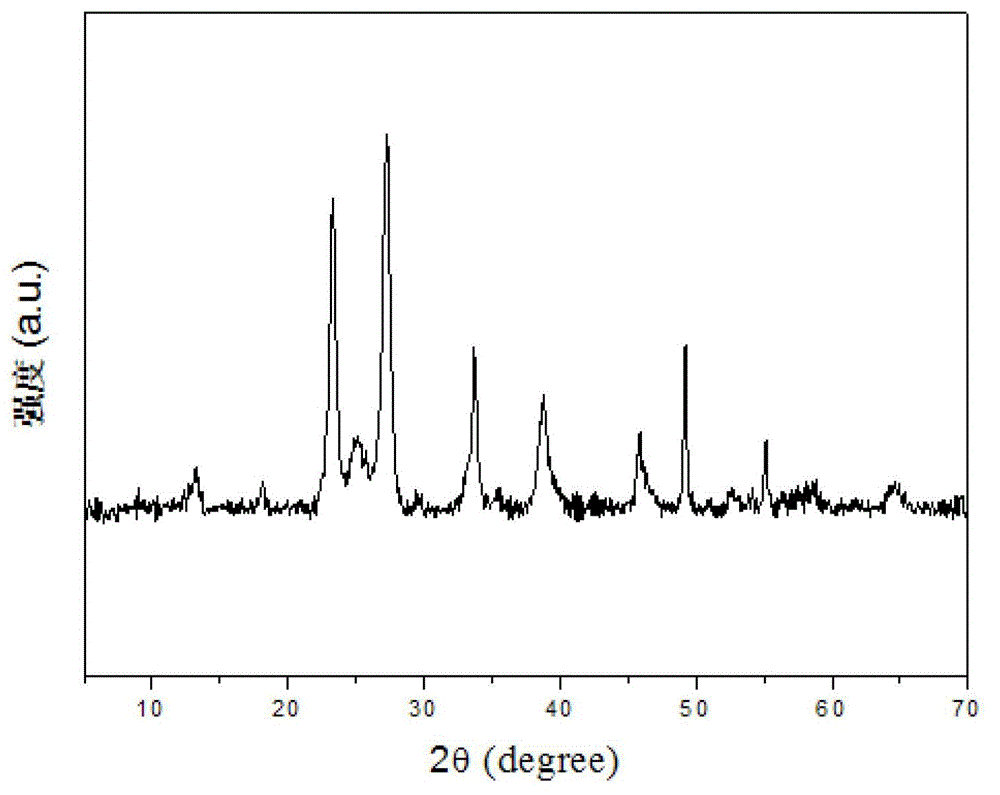

Preparation method and application of multistage-structured flower-shaped molybdenum trioxide

A technology of molybdenum trioxide and flower shape, which is applied in the field of preparation of molybdenum trioxide, can solve the problems of complex process, high reaction temperature, and low sensitivity of propanol, and achieve simple and efficient preparation process, low hydrothermal temperature, good gas The effect of sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0017] Specific embodiment one: the preparation method of multi-level structure flower-shaped molybdenum trioxide of the present embodiment is implemented according to the following steps:

[0018] 1. Transfer the glacial acetic acid solution of oxymolybdenum acetylacetonate with a molar concentration of 0.008-0.012 mol / L to the reaction kettle, heat and react at 140-160°C for 1-8 hours, and obtain a black powder;

[0019] 2. Wash the black powder obtained in step 1 with absolute ethanol for 3 to 5 times, and then vacuum-dry at 60 to 70° C. for 8 to 15 hours to obtain molybdenum trioxide with a multi-level flower shape.

specific Embodiment approach 2

[0020] Embodiment 2: This embodiment is different from Embodiment 1 in that step 1 is heated and reacted at 145-153°C for 3-6 hours. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0021] Embodiment 3: This embodiment is different from Embodiment 1 in that step 1 is heated and reacted at 151° C. for 4 hours. Other steps and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com