Nano Co3O4/TiO2 semiconductor composite film and application thereof

A composite film, semiconductor technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of easy recombination of photogenerated carriers, low utilization of visible light of photoanodes, etc. The effect of low temperature, increased visible light absorption, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] co 3 o 4 / TiO 2 The preparation of composite film light comprises the following steps:

[0038] A titanium foil with a purity of 99.9 wt.% and a thickness of 0.3 mm was cut into a rectangular titanium sheet of 1 cm×3 cm. Soak the titanium sheet in ethanol solution for 30 minutes to remove surface oil and other impurities. Afterwards, the titanium sheet was rinsed with distilled water and ultrasonically cleaned twice with distilled water for 10 min each time to further remove oil stains. The titanium sheet after ultrasonication is rinsed with ethanol to remove water, and finally the cleaned titanium sheet is soaked in ethanol for later use.

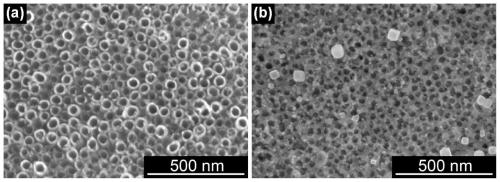

[0039] TiO 2 The nanotube array film is prepared by anodic oxidation and calcined. Using a two-electrode system, the above-mentioned titanium sheet was dried as a working electrode, and a platinum electrode was used as a counter electrode. The two electrodes were respectively placed in the electrolyte, and oxidized for 1 hour ...

Embodiment 2

[0048] co 3 o 4 / TiO 2 The preparation of composite film light comprises the following steps:

[0049] A titanium foil with a purity of 99.9 wt.% and a thickness of 0.3 mm was cut into a rectangular titanium sheet of 1 cm×3 cm. Soak the titanium sheet in ethanol solution for 30 minutes to remove surface oil and other impurities. Afterwards, the titanium sheet was rinsed with distilled water and ultrasonically cleaned twice with distilled water for 10 min each time to further remove oil stains. The titanium sheet after ultrasonication is rinsed with ethanol to remove water, and finally the cleaned titanium sheet is soaked in ethanol for later use.

[0050] TiO 2 The nanotube array film is prepared by anodic oxidation and calcined. Using a two-electrode system, the above-mentioned titanium sheet was dried as a working electrode, and a platinum electrode was used as a counter electrode. The two electrodes were respectively placed in the electrolyte, and oxidized for 1 hour ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com