Cooling and heating central control device of public bus

A centralized control, passenger car technology, applied in vehicle components, transportation and packaging, heating/cooling equipment, etc., can solve problems such as uneven passengers, comfort impact, no associated control, etc., to ensure service life, improve comfort, The effect of noise suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

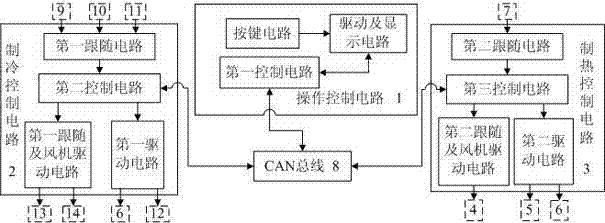

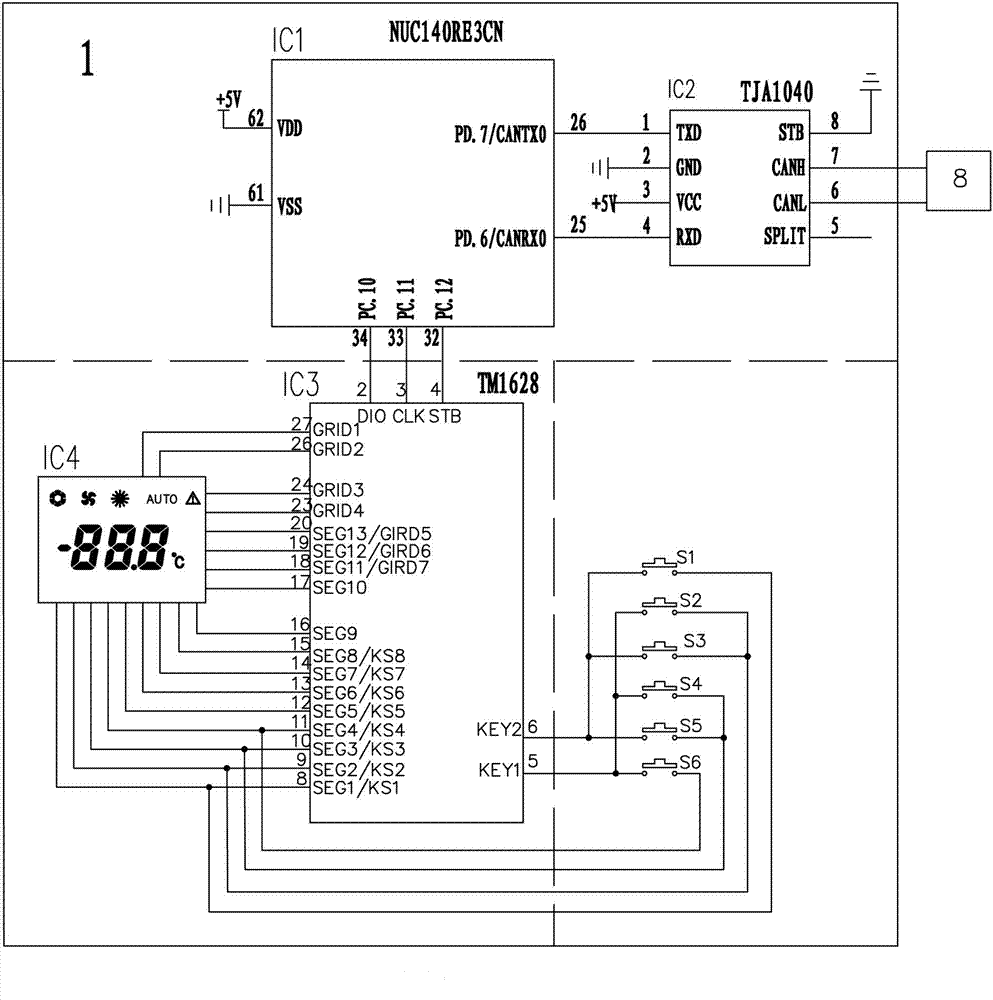

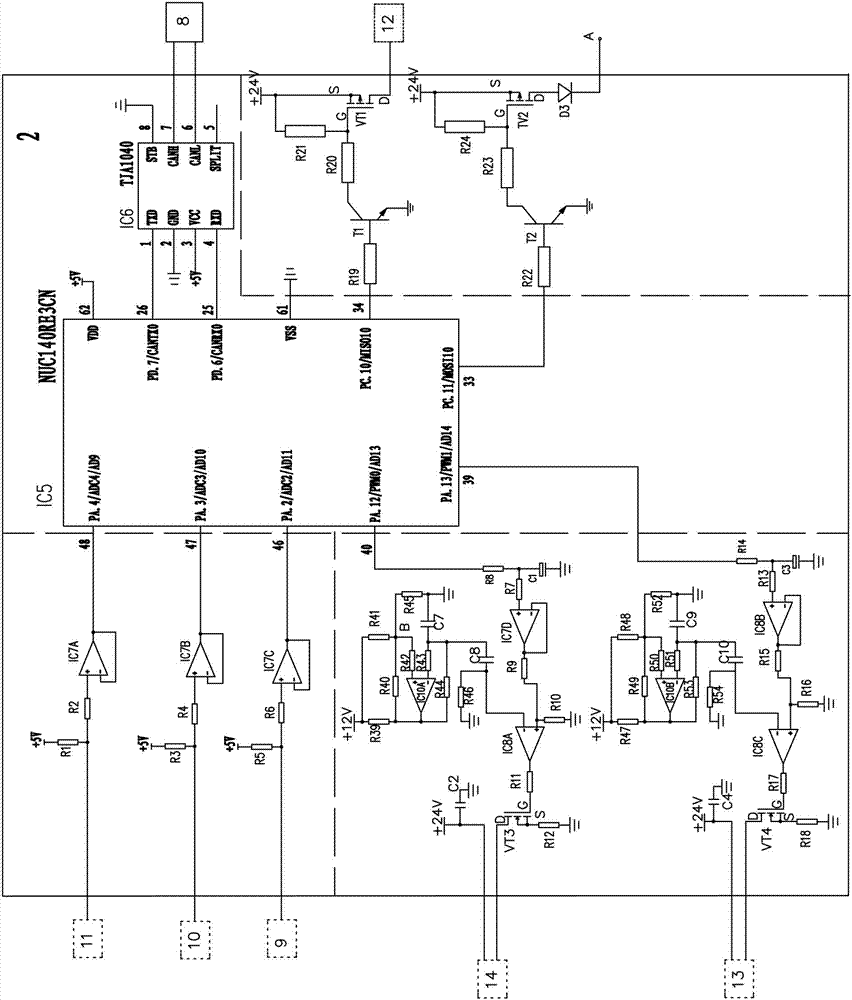

[0023] attached by Figure 1-4 It can be known that this embodiment is composed of an operation control circuit 1, a refrigeration control circuit 2 (hereinafter referred to as the refrigeration module) and a heating control circuit 3 (hereinafter referred to as the heating module); the operation control circuit 1, the refrigeration control circuit 2, the heating control circuit The circuit 3 is connected through the CAN bus 8; the operation control circuit 1 is composed of a first control circuit, a drive and display circuit and a button circuit; the first control circuit is connected with the CAN bus 8, and the first control circuit is connected with the drive and display The circuit is bidirectionally connected; the output terminal of the key circuit is connected to the corresponding input terminal of the driving and display circuit;

[0024] The refrigeration control circuit 2 is composed of a first follower, a second control circuit, a first follower, a fan drive circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com