Sealing dipping pultrusion system device for producing optical fiber reinforced core and preparation method

A fiber optic cable strengthening core and dipping device technology, applied in the field of fiber optic cable strengthening core devices, can solve problems such as thickening, obstructive pulmonary lesions, rough and cracked skin, etc., and achieve high strength, long service life and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

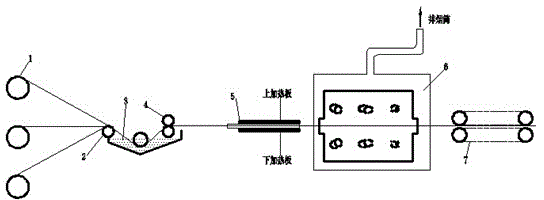

[0023] attached Figure 4 It is an embodiment of the present invention.

[0024] Below in conjunction with accompanying drawing, content of the invention will be further described:

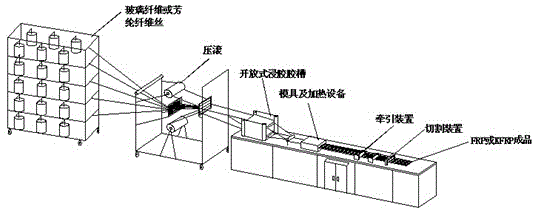

[0025] refer to Figure 4 As shown, the sealing and dipping pultrusion system device for the production of optical cable reinforcing core consists of a glass fiber roving creel arrangement device, a yarn guide frame, a glue groove, a preforming mold, a heating molding mold, a mechanical traction device, and a winding coil garden device Composition: An infrared heating and moisture removal device is installed at intervals on the right side of the yarn guide frame, a sealing pressure dipping device is installed at intervals on the right side of the heating and moisture removal device, and the upper end of a transparent sealed glue storage tank passes through the 1# valve and pipeline and the glue inlet connected, the lower end of the transparent sealed glue storage tank is connected to the sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com