Gas cutting method, gas cutting device and cutting nozzle

A nozzle and gas cutting technology, applied in combustion methods, welding/cutting media/materials, lighting and heating equipment, etc., can solve the problems of reducing the ratio of mixed hydrocarbon gas or liquefied petroleum gas, low cutting performance, explosion, etc. Superior cutting performance, improved safety, easy to adjust results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] Hereinafter, a gas cutting method to which one embodiment of the present invention is applied will be described together with a gas cutting device and a cutting nozzle used therefor, using the drawings. In addition, in the drawings used in the following description, in order to make the characteristics easier to understand, the characteristic parts may be enlarged and shown for convenience, and the dimensional ratio of each component is not limited to be the same as the actual one.

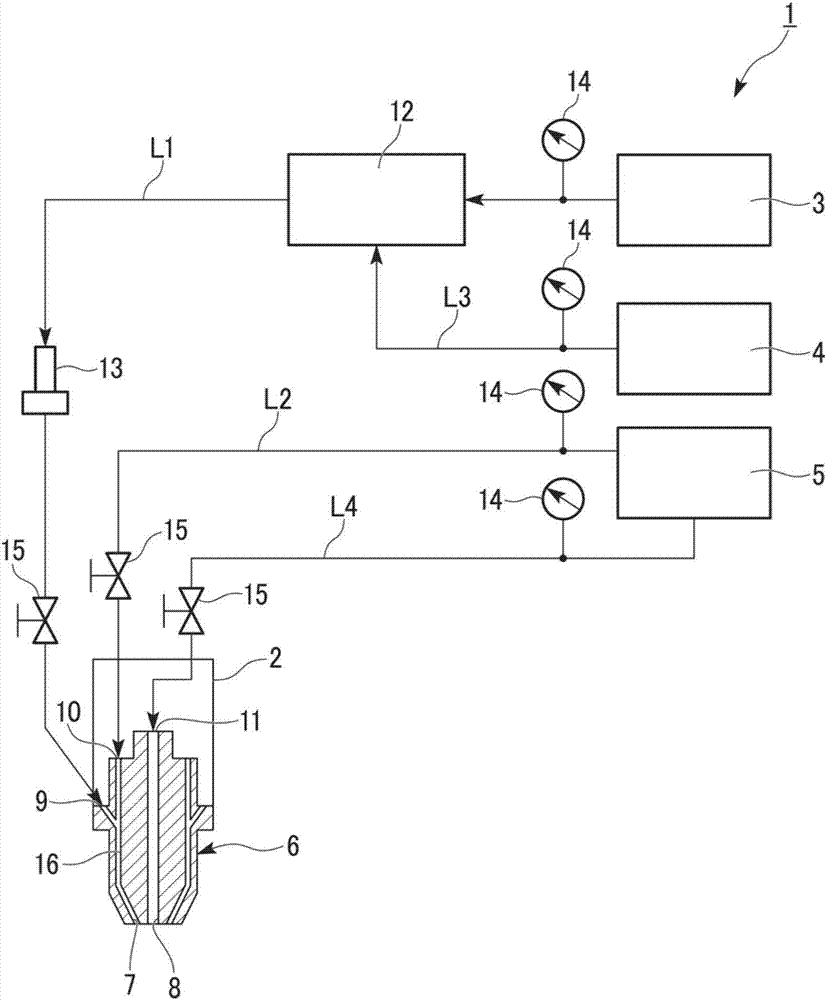

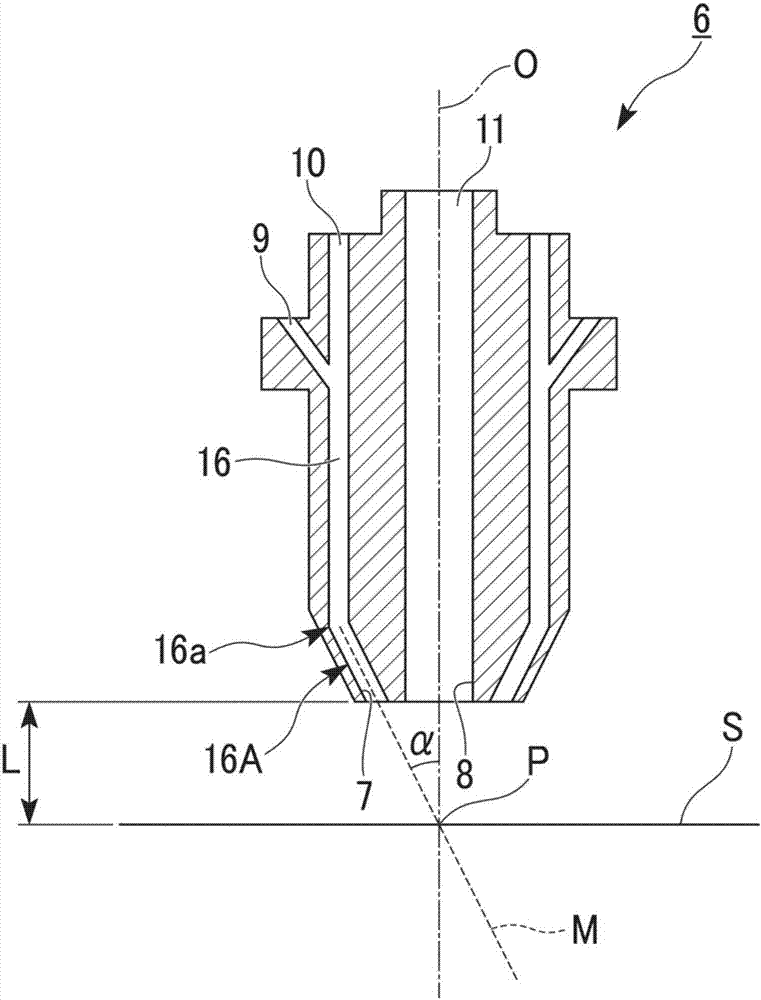

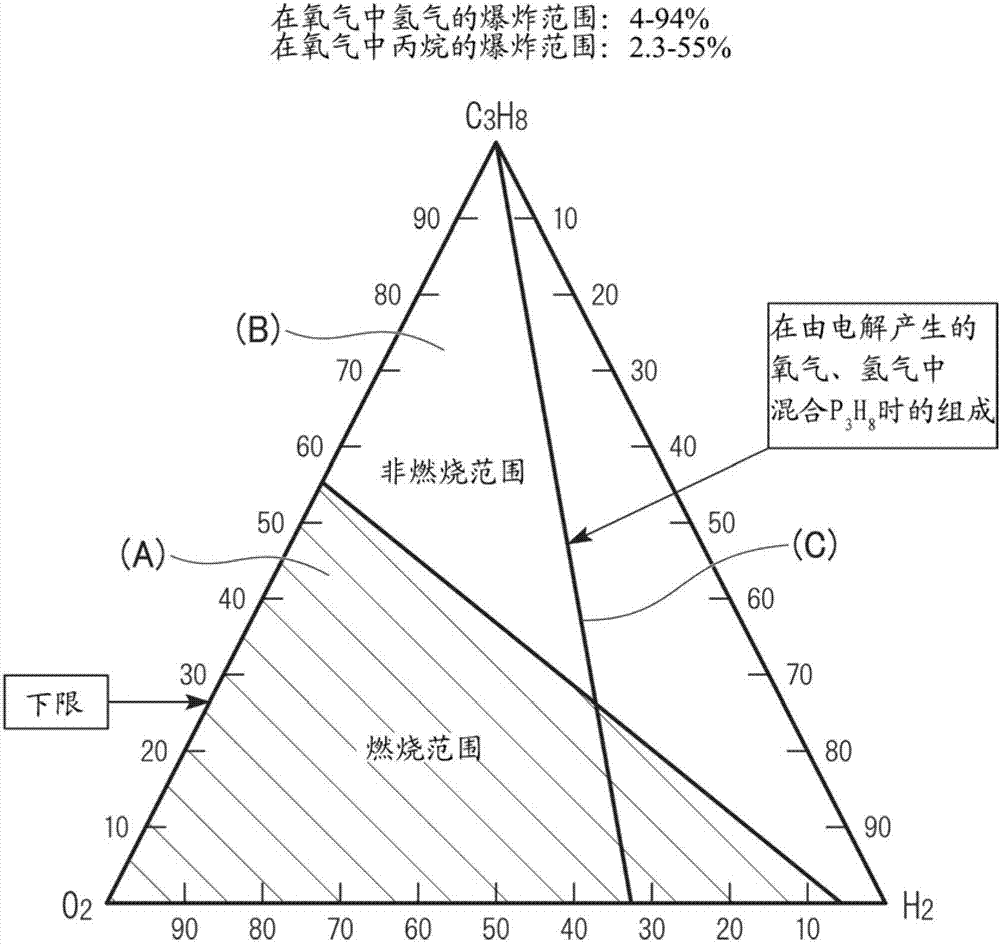

[0082] figure 1 It is a system diagram which shows the gas cutting apparatus used for the gas cutting method which concerns on one Embodiment of this invention. Such as figure 1 As shown, the gas cutting device 1 of the present embodiment has: a cutting torch 2 with a cutting nozzle 6, the cutting nozzle 6 is provided with a preheating hole 7 and a cutting oxygen hole 8; a hydrogen supply source 3 for supplying hydrogen; Hydrocarbon gas supply source 4; oxygen supply source 5 for supply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com