Exhaust gas catalytic purging unit using selective reduction catalyst, exhaust gas purging method, and diesel automobile equipped with exhaust gas catalytic purging unit

A catalyst device, exhaust gas purification technology, applied in catalyst activation/preparation, catalyst regeneration/reactivation, exhaust device, etc., can solve problems such as engine output power reduction and filter clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

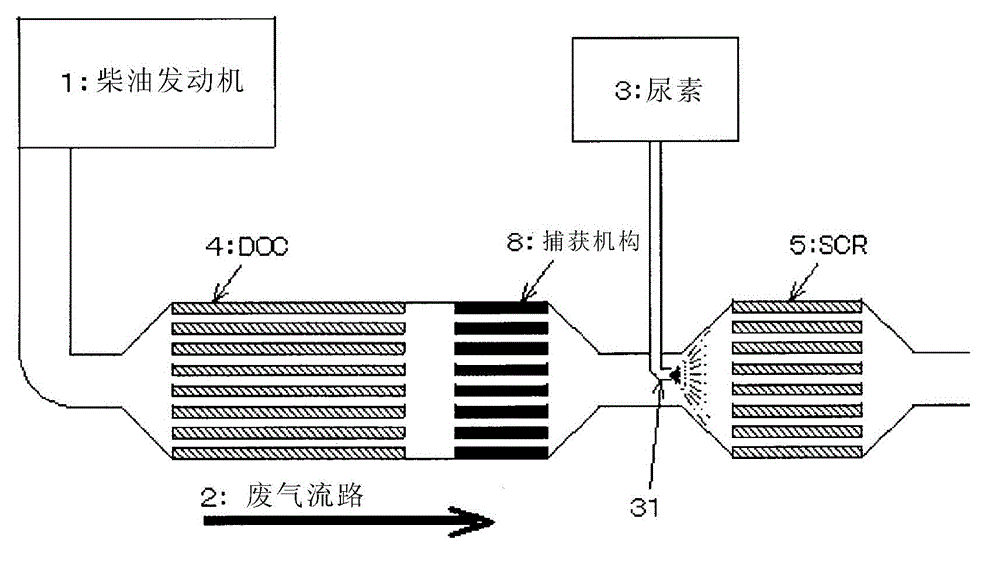

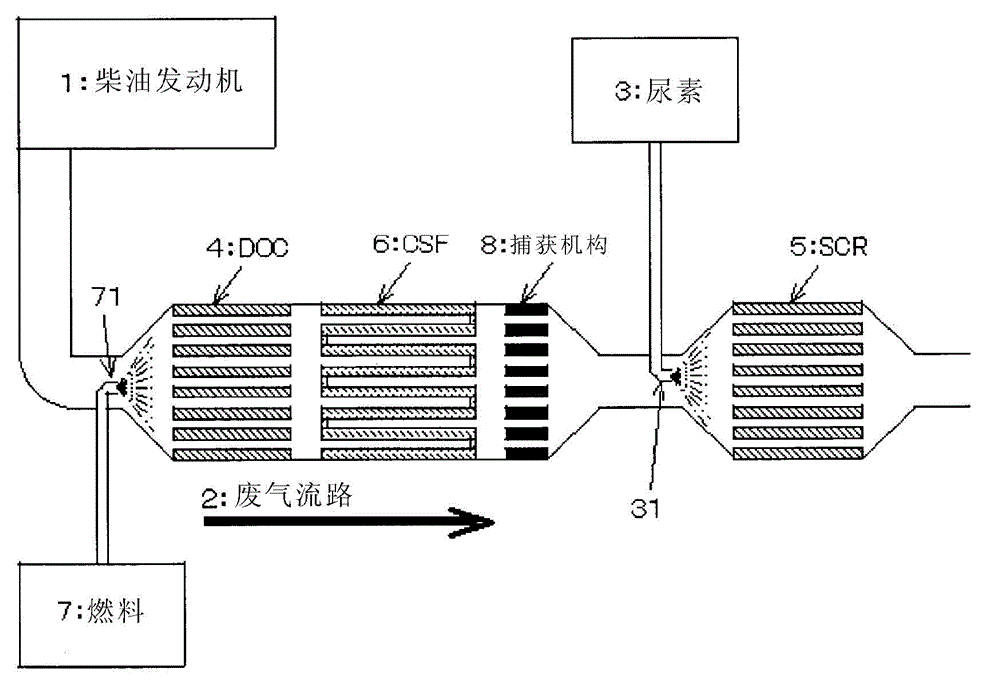

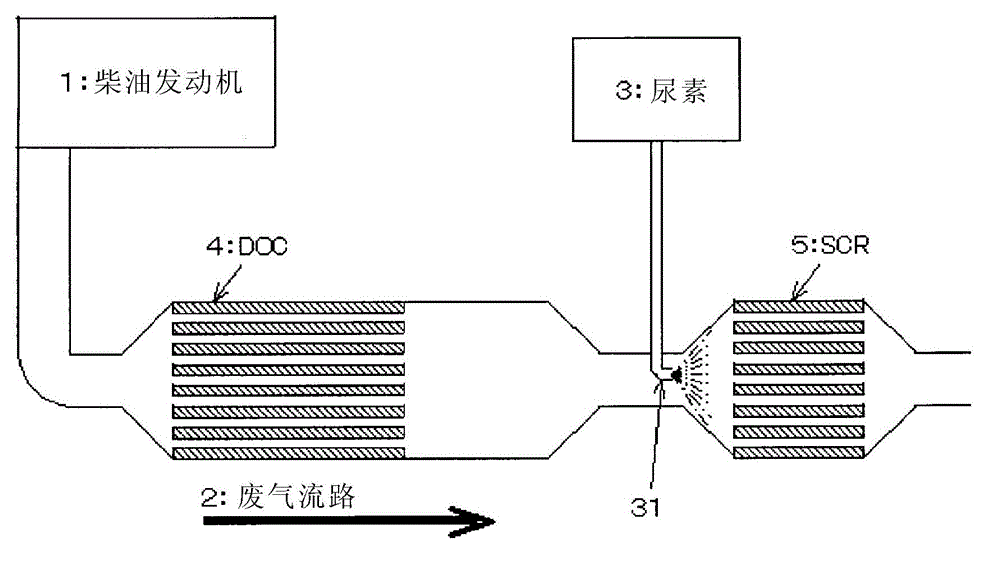

[0209] The above-mentioned oxidation catalyst 1, oxidation catalyst 2, oxidation catalyst 3, trapping mechanism 1, trapping mechanism 2, and SCR1 were arranged in an exhaust pipe (diameter 24 mm, length 700 mm) as shown in Table 2, and the exhaust gas catalyst of the present invention was obtained. device. Using this apparatus, aging was performed by circulating heated air at 900° C. for 20 hours at a flow rate of 10 [L / min]. In addition, the distance between the oxidation catalyst and the capture mechanism was 15 mm and the distance between the capture mechanism and the SCR 1 was 200 mm when aging was performed according to the examples. In addition, when using two oxidation catalysts, the distance between oxidation catalysts was 15 mm. In addition, in the burn-in test for the comparative example in which the trapping mechanism was not arranged, only the trapping mechanism was not disposed, and the arrangement was the same as the evaluation in the examples.

[0210] Table 2...

Embodiment 7

[0227] The above-mentioned oxidation catalyst 3 and capture mechanism 2 are arranged like "oxidation catalyst 3 + capture mechanism 2", aged under the aforementioned aging conditions, and the amount of precious metal adsorbed on the capture mechanism 2 is determined by ICP-AES (Inductively Coupled Plasuma-Atomic Emission Spectrometry, inductively coupled plasma-atomic emission spectrometry).

[0228] In addition, except that the capture mechanism 2 was not used, the same operation was carried out as in Examples 5 and 6, and oxidation catalysts 1 and 2 and SCR 1 were arranged in the exhaust pipe as shown in Table 2 to obtain an exhaust gas catalyst device for comparison. . Using this device, aging was similarly performed.

[0229] As a result, it was found that the amount of the Pt component in terms of metal was 15 ppm, and the amount of the Pd component in terms of metal was less than 1 ppm.

[0230] From this, it can be seen that the volatilization amount of the Pt compone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com