Pole plate assembling device of automatic piece coating machine

A technology of automatic wrapping machine and assembly device, which is applied in the field of wrapping machines, and can solve problems such as poor wrapping quality, health impact of operators, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

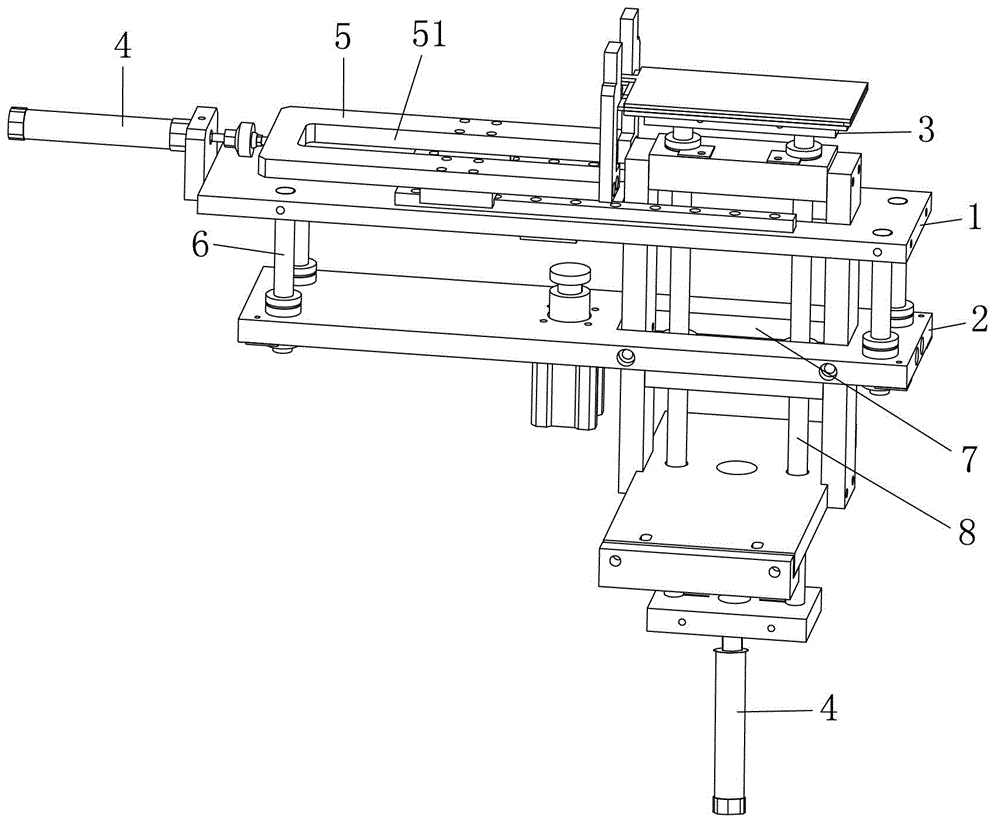

[0012] The invention provides a pole plate assembly device of an automatic wrapping machine. The pole plate assembly device is installed at the discharge port of the wrapping machine. The pole plate assembly device includes a support bracket, a support cylinder and a support plate. The support The cylinder drives the supporting plate up and down through the transmission column, and the supporting plate corresponds to the discharge port of the wrapping machine. The supporting plate is set under the outlet of the wrapping machine. When the plate group falls from the outlet of the wrapping machine, the supporting plate supports the plate group, and the supporting cylinder drives the supporting plate down by one level through the transmission column. The height of the plate group allows space for one plate group to hold the next plate group, and the height of the support plate can be adjusted by the support cylinder to meet the number of plates in the pole group. .

[0013] The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com