Method for optimizing crystalline silicon solar cell diffusion square resistance uniformity

A technology of solar cells and square resistors, applied in circuits, electrical components, climate sustainability, etc., can solve problems such as cost increases, and achieve the effects of increasing production costs, reducing leakage current, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with example and accompanying drawing, the present invention is described in further detail.

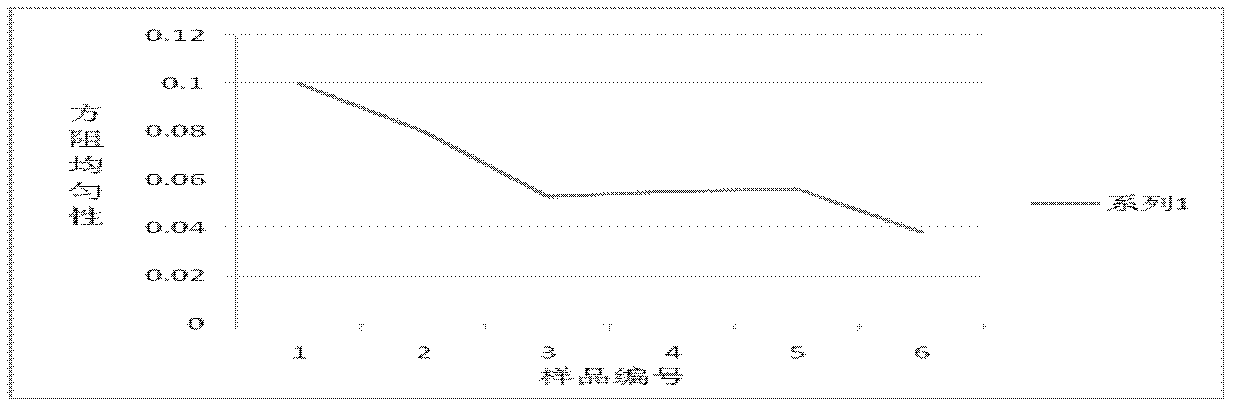

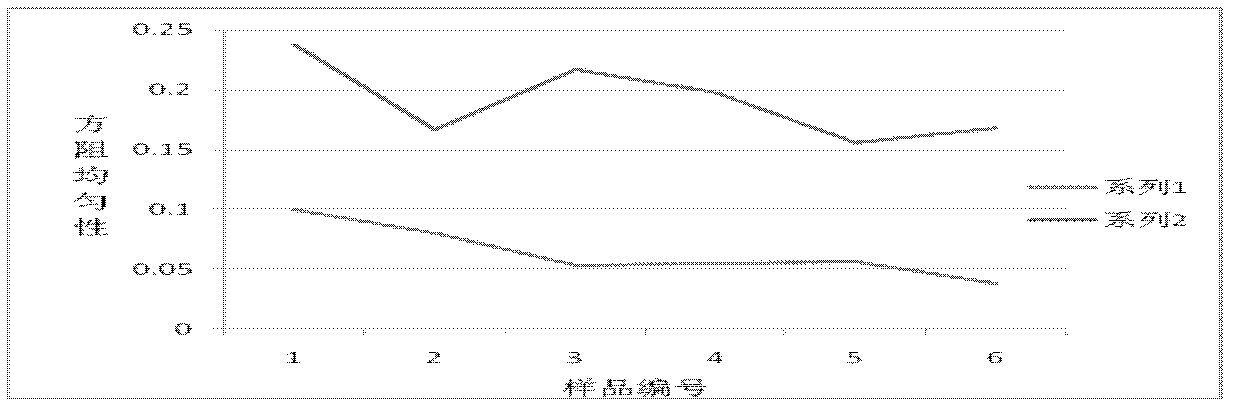

[0016] The purpose of the present invention is to improve the uniformity of diffusion sheet resistance through this process, so that the distribution of sheet resistance is more uniform and reasonable. After adding the oxide layer, the uniformity of the sheet resistance and the parallel resistance are improved, thereby improving the photoelectric conversion efficiency of the solar cell to a certain extent.

[0017] The present invention comprises following four steps:

[0018] (1) Put the silicon wafer into the diffusion furnace, and make a layer of SiO on the surface of the silicon wafer 2 For the oxide layer, the temperature is controlled at 850°C~870°C, and then 1800ml / min of dry oxygen (oxygen) and 24000ml / min of large nitrogen (nitrogen) are introduced for 150s.

[0019] (2) Carry out a diffusion, one of which is divided into two small steps of diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com