Anticorrosion and acid-resistant glue for wet desulfurization chimney and preparation method thereof

A wet desulfurization and chimney technology, which is applied in the direction of anti-corrosion coatings, adhesives, polycarbonate coatings, etc., can solve problems such as waste, and achieve the effects of increasing the service life, saving operating costs, and reducing the impact on personnel health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

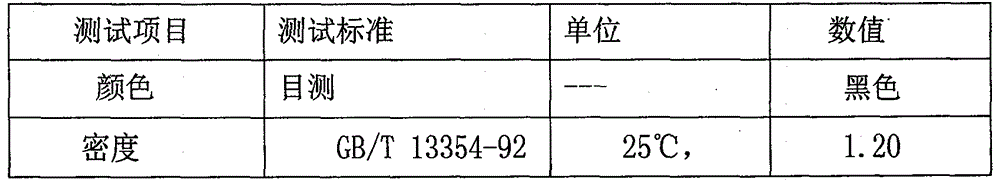

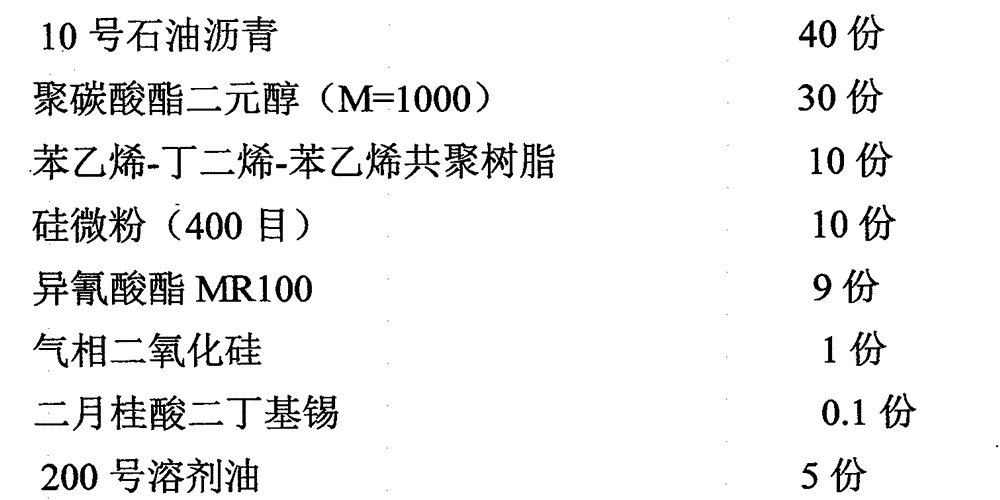

Embodiment 1

[0070]

[0071] In the first step, the No. 10 petroleum pitch, polycarbonate diol and styrene-butadiene-styrene copolymer resin are heated in the kettle until No. 10 petroleum pitch melts, and two high-shear The emulsifier emulsifies and disperses the asphalt and the other two components evenly, the temperature of the kettle is controlled at 150-200 degrees, and the vacuum pressure in the kettle is controlled at 200-300Pa;

[0072] The second step is to close the emulsifier, open the atmosphere, put in the above-mentioned silicon micropowder, dibutyltin dilaurate and white carbon black, open the high-speed disperser under vacuum and heat preservation, and disperse at 600-1500 rpm to obtain a paste-like finished product , the vacuum pressure is controlled at 200-300Pa, the kettle temperature is controlled at 110-130 degrees, and the moisture in the system is fully removed;

[0073] The third step is to put in No. 200 solvent oil and quickly disperse evenly under airtight con...

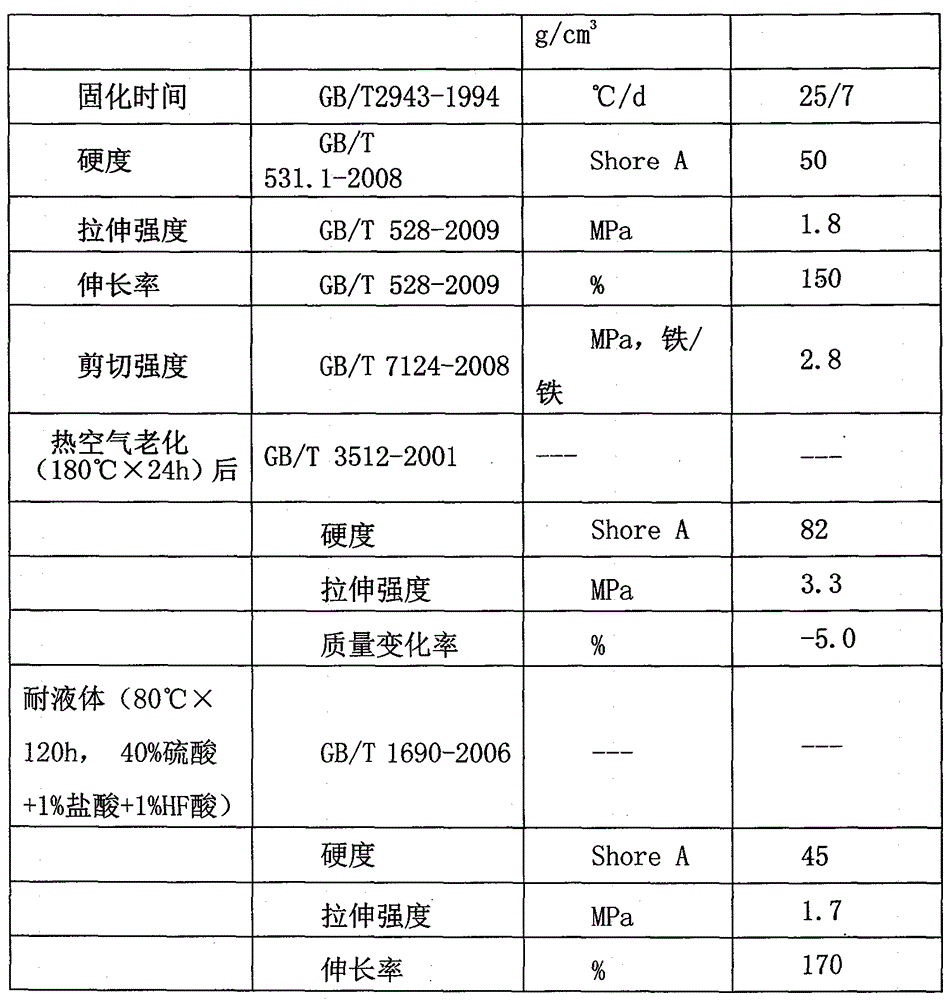

Embodiment 2

[0077]

[0078] In the first step, the No. 10 petroleum pitch, polycarbonate diol (M=2000) and styrene-butadiene-styrene copolymer resin are heated in a kettle until No. 10 petroleum pitch is melted, and the Turn on two high-shear emulsifiers to emulsify and disperse the asphalt and the other two components evenly, control the temperature of the kettle at 150-200 degrees, and control the vacuum pressure in the kettle at 200-300Pa;

[0079] The second step is to close the emulsifier, open the atmosphere, put in the above-mentioned silicon micropowder, dibutyltin dilaurate and white carbon black, open the high-speed disperser under vacuum and heat preservation, and disperse at 600-1500 rpm to obtain a paste-like finished product , the vacuum pressure is controlled at 200-300Pa, the kettle temperature is controlled at 110-130 degrees, and the moisture in the system is fully removed;

[0080] The third step is to put in No. 200 solvent oil and quickly disperse evenly under airt...

Embodiment 3

[0084]

[0085] Shear strength (steel-steel) After 2MPa acid soaking (40% sulfuric acid, 80 degrees Celsius, 7 days), the tensile strength retention rate is 110%.

[0086] Note: The curing condition of the above formula is 7 days at 25 degrees Celsius.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com