Special coagulation-delaying high-efficiency slushing agent for dam roller compacted concrete

A high-efficiency water-reducing agent and roller compacted concrete technology, which is applied in the field of concrete admixtures in building materials, can solve the problems of high cost, discrete concrete, and single reinforcement method of roller compacted concrete, etc., achieves low cost, improves cohesion, realizes The effect of relative stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A special retarding high-efficiency water reducer for dam roller compacted concrete, the weight percentage of each component is: naphthalene sulfonate formaldehyde condensate 57%, sodium lignosulfonate 15%, sugar calcium 10%, sodium gluconate 5%, maltodextrin 0.85%, anhydrous sodium sulfate 6%, calcium chloride 6%, a mixture of polyacrylamide and sodium hydroxymethylcellulose in a ratio of 1:1 0.15%. This example is mainly used in the preparation of dam RCC during spring and autumn.

Embodiment 2

[0022] A special retarding high-efficiency water reducer for dam roller compacted concrete, the weight percentage of each component is: naphthalenesulfonate formaldehyde condensate 53%, calcium lignosulfonate 5%, sugar calcium 20%, sodium gluconate 9%, maltodextrin 0.8%, anhydrous sodium sulfate 6%, calcium chloride 6%, a mixture of polyacrylamide and sodium hydroxymethylcellulose in a ratio of 1:1 0.2%. This example is mainly used in the preparation of dam RCC in summer.

Embodiment 3

[0024] A special retarding high-efficiency water reducer for dam roller compacted concrete, the weight percentage of each component is: naphthalenesulfonate formaldehyde condensate 60%, sodium lignosulfonate 20%, sugar calcium 5%, sodium gluconate 2%, Maltodextrin 0.9%, Anhydrous Sodium Sulfate 6%, Calcium Chloride 6%, Polyacrylamide and Sodium Hydroxymethyl Cellulose in a ratio of 1:1 0.1%. This example is mainly used in the preparation of dam RCC in winter.

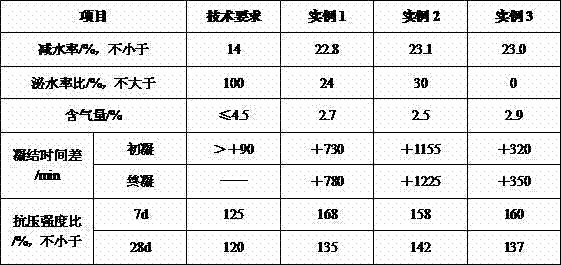

[0025] Implementation Effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water reduction rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com