Lithium secondary battery consistency screening method

A technology of lithium secondary battery and screening method, applied in the direction of climate sustainability, sustainable manufacturing/processing, final product manufacturing, etc. Good market application prospect and small hidden danger of self-power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

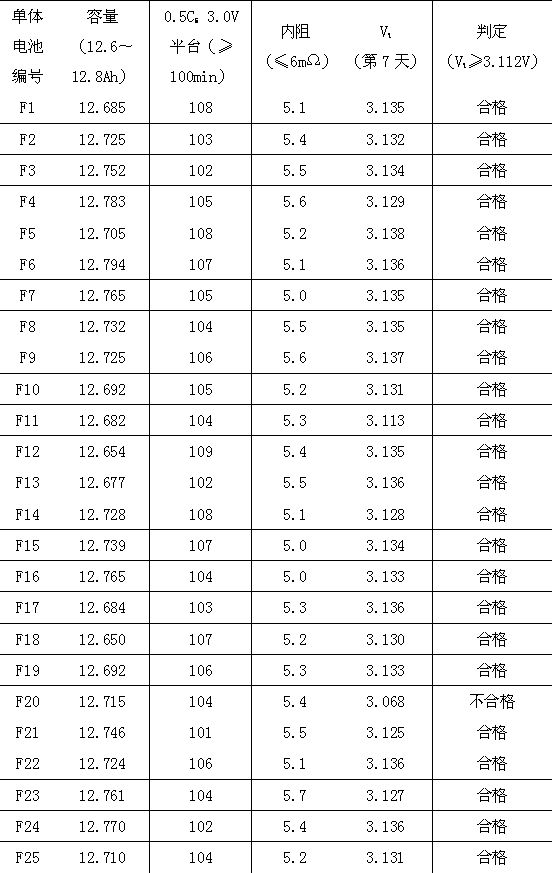

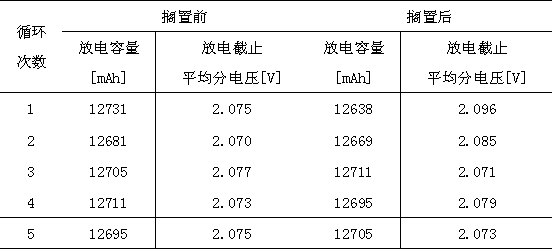

[0029] Example 1: The 9585175Fe lithium iron phosphate lithium-ion battery produced by our company has a nominal voltage of 3.2V and a rated capacity of 12Ah. According to the production and delivery requirements, the time from the completion of charging to the packaging of a single battery is 7 days.

[0030] According to the method of the present invention, after the single battery is formed into capacity, the selected capacity grade is 12.6~12.8Ah, 0.5 C 5 Discharge single battery with 3.0V platform ≥ 100 minutes, internal resistance ≤ 6mΩ, select V 0 3.15V, using 0.3 C 5 Constant current charging to 3.15V, and then constant voltage to 3.15V for constant voltage charging, when the charging current is 0.1 C 5 Stop charging and turn to shelve; continue to charge at 0.1 C after 10 minutes of shelving 5 Constant current charging to 3.15V, and then constant voltage to 3.15V for constant voltage charging, when the charging current is 0.05 C 5 Stop charging and turn to shelve; ...

Embodiment 2

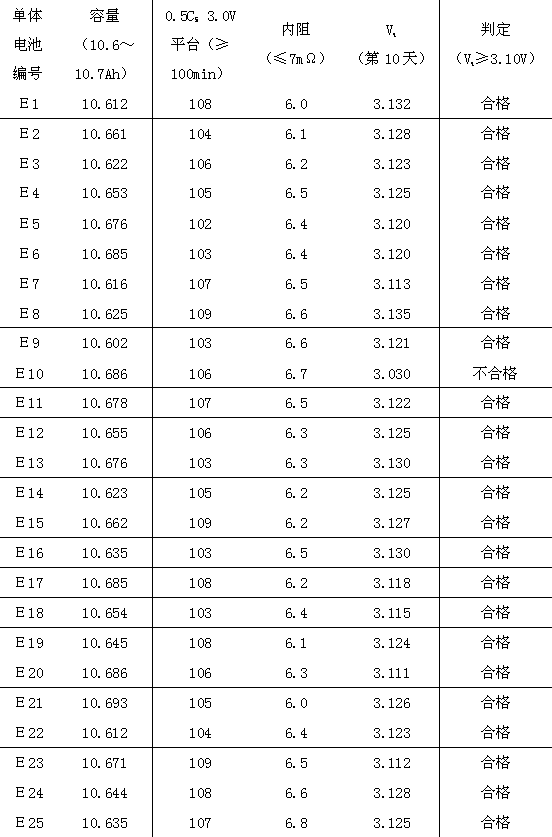

[0040] Example 2: The 11585135Fe lithium iron phosphate lithium-ion battery produced by our company has a nominal voltage of 3.2V and a rated capacity of 10Ah. According to the production and delivery requirements, the time from the completion of charging to the packaging of a single battery is 10 days.

[0041] According to the method of the present invention, after the capacity of the single battery is completed, the selected capacity grade is 10.6~10.7Ah, 0.5 C 5 Discharge single battery with 3.0V platform ≥ 100 minutes, internal resistance ≤ 7mΩ, use 0.1C 5 Constant current charge to voltage V 0 is 3.15V, and then the constant voltage is 3.15V for constant voltage charging, when the charging current is 0.01 C 5 Charging is stopped at this time, and then the single battery is left at room temperature for 10 days, then the open circuit voltage of the battery is measured, and the single battery with large self-consumption is eliminated.

[0042] According to the method of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com