Production method of polyacrylonitrile chelating resin metal adsorbent

A chelating resin, polyacrylonitrile technology, used in chemical instruments and methods, other chemical processes, etc., can solve the problems of polluted environment, low elution rate, etc., and achieve large adsorption capacity, good thermal stability, and high mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The production method of embodiment 1, polyacrylonitrile chelating resin metal adsorbent comprises the following steps:

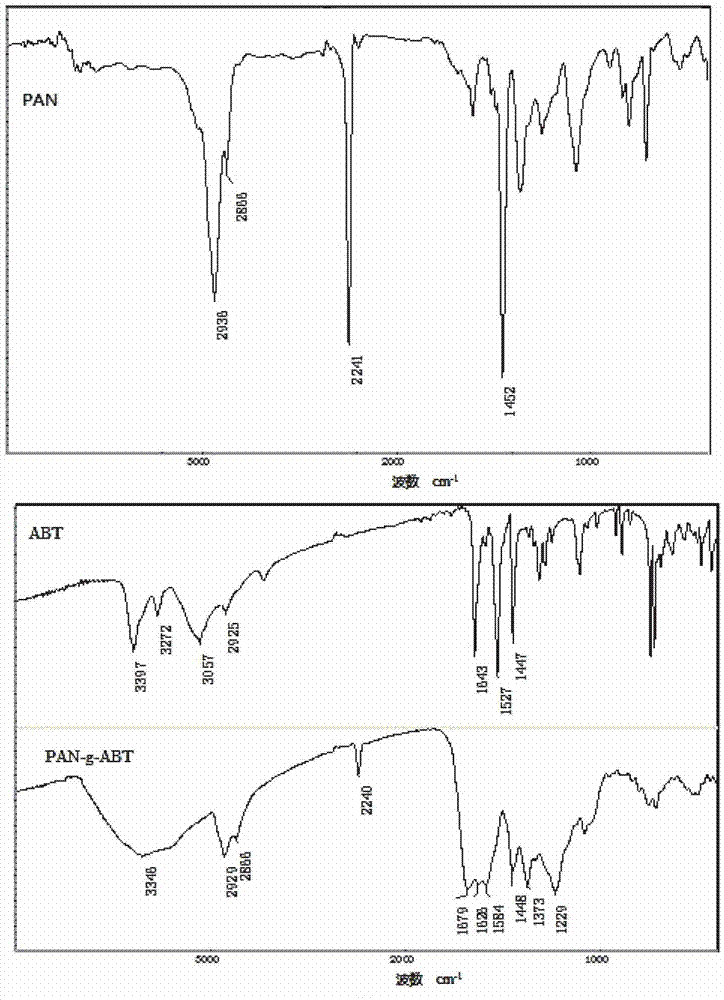

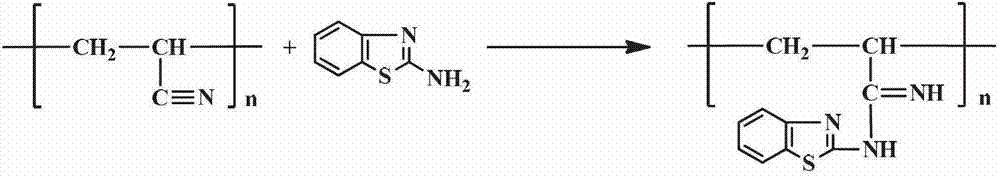

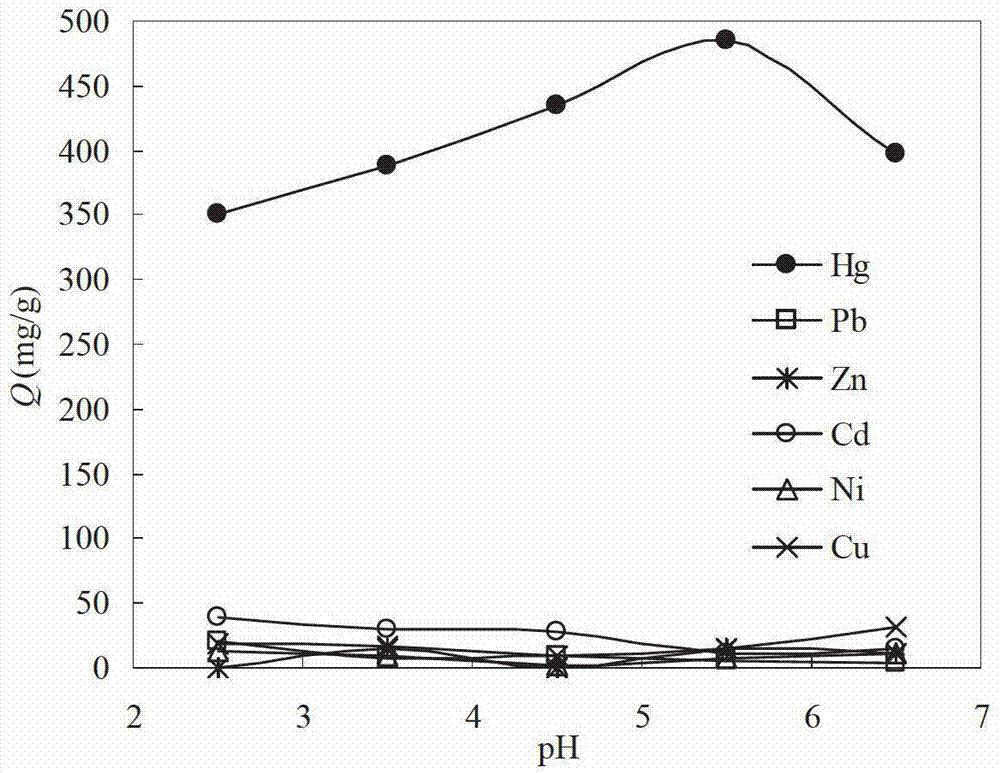

[0048] 1. Using polyacrylonitrile microspheres (D-160 macroporous adsorption resin) as the matrix and 2-aminobenzothiazole (ABT) as the ligand, the polyacrylonitrile microspheres are chemically grafted, and the following steps are carried out in sequence:

[0049] ① Weigh 500 mg of polyacrylonitrile microspheres, transfer them into a 500 mL three-necked bottle, add 300 mL of reaction solvent --- ethylene glycol (ED), soak overnight (that is, soak for 24 hours, so that polyacrylonitrile The microspheres are fully swollen);

[0050] ②. Add 3.57g of ligand --- 2-aminobenzothiazole (ABT) and a little catalyst --- - Sodium metal (1240 mg), heated and stirred (250r / min) at 140°C under nitrogen protection for 12 hours; after the reaction, filtered to obtain the modified polyacrylonitrile chelating resin;

[0051] ③. Soak the modified polyacrylonitrile che...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com