Energy-saving tall bungalow granary

A granary and bungalow technology, applied in the field of energy-saving tall and large bungalow granaries, can solve the problems of large power consumption and high summer temperature in warehouses, and achieve the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

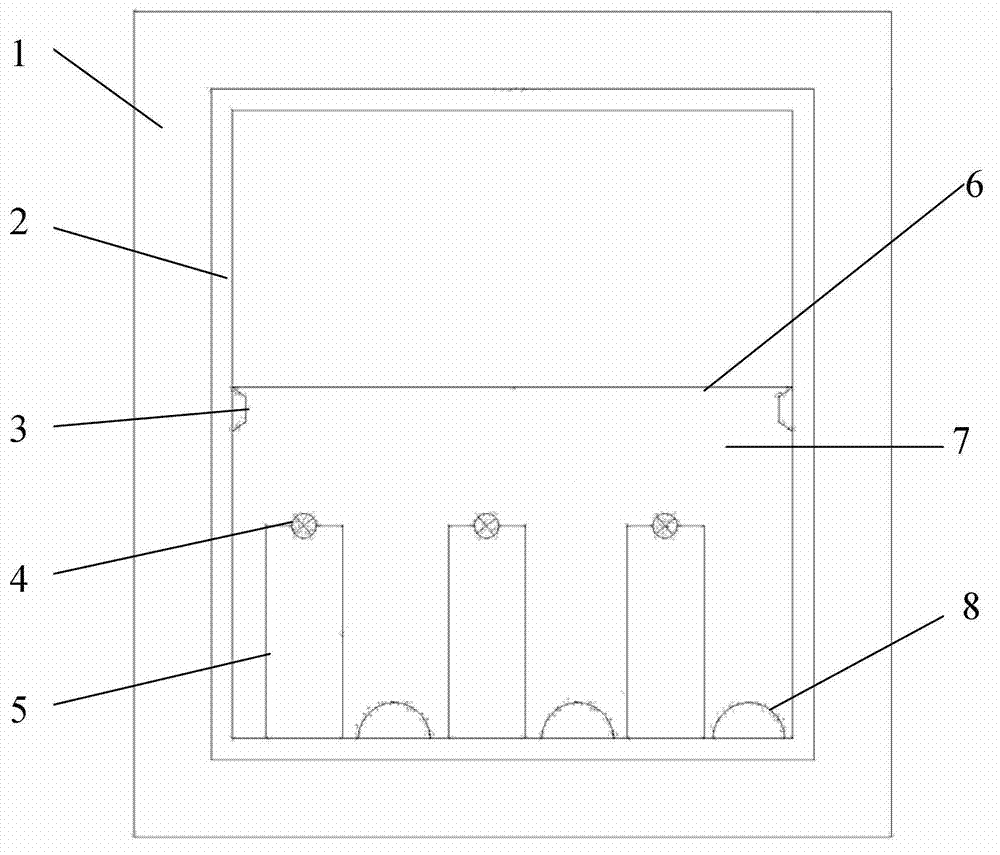

[0011] The structure of the energy-saving tall one-story granary of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0012] Such as Figure 1-Figure 3 As shown, the inside of the wall 1 of the energy-saving tall bungalow granary and the top and bottom of the granary are all provided with insulation boards 2, the top of the grain pile 7 in the granary is covered with a heat insulation film 6, and a ventilation device is arranged in the grain pile 7 , a ground cage 8 is arranged on the insulation board at the bottom of the granary.

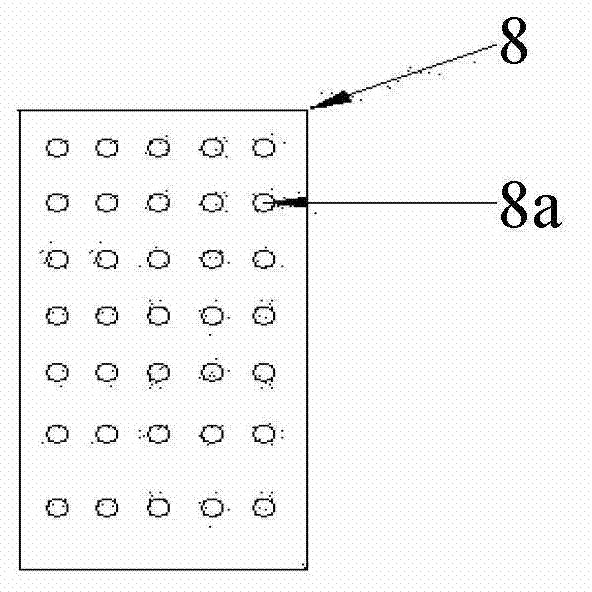

[0013] The ventilation device includes a ventilation pipeline 5 and a "non"-shaped ventilation pipe 9 formed on both sides of the ventilation pipeline, and a ventilation pump 4 is installed on the ventilation pipeline. There are a plurality of micropores 8a on the surface of the ground cage 8, and anti-insect drugs are placed in the ground cage 8.

[0014] The thermal insulation film 6 adopts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com