Gas diffusion layer for unitized regenerative fuel cell, and its preparation method

A gas diffusion layer and fuel cell technology, which is applied in the parts of fuel cells, etc., can solve problems such as non-conductivity, achieve strong flexibility, solve high-potential corrosion, and light material.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

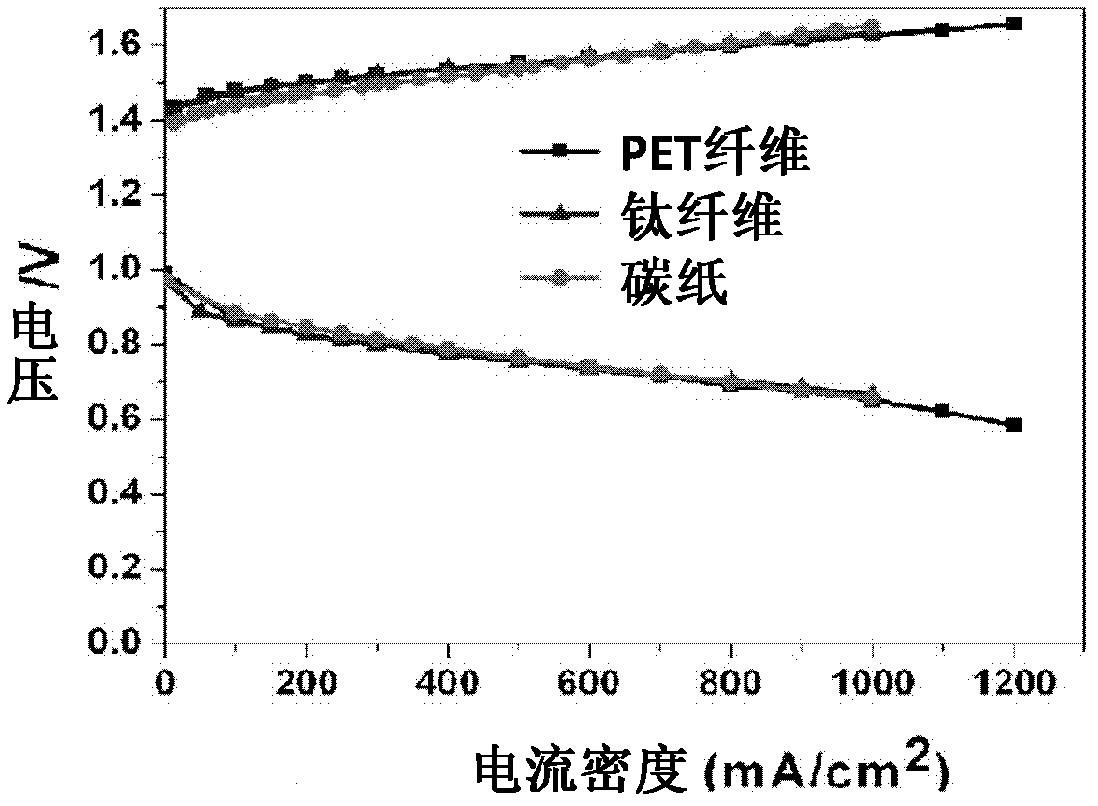

Embodiment 1

[0041] 1) Hydrophobic treatment of the substrate

[0042] Cut 2×2.5cm 2 The carbon paper was soaked in 1wt% PTFE emulsion for multiple times for hydrophobic treatment, and then fired at 360°C for 1 hour to obtain the hydrophobized carbon paper;

[0043] 2) Add ethanol to the 50mg IrO2 / Ti leveling material, add 200mg20wt% PTFE emulsion after mixing evenly, obtain the leveling layer slurry after mixing evenly, apply the slurry evenly on the carbon paper after the hydrophobization treatment, and then Calcined at 360° C. for 1 hour to obtain a hydrophobic diffusion layer supported by carbon paper.

Embodiment 2

[0045] 1) Hydrophobic treatment of the substrate

[0046] Cut 2×2.5cm 2 The titanium fiber net is dipped in 1wt% PTFE (polytetrafluoroethylene) emulsion for many times to carry out hydrophobic treatment, and then baked at 360 ° C for 1 hour to make it hydrophobic;

[0047]2) Add ethanol to the 50mg IrO2 / Ti leveling material, add 200mg20wt% PTFE emulsion after mixing evenly, obtain the leveling layer slurry after mixing evenly, apply the slurry evenly on the carbon paper after the hydrophobization treatment, and then Calcined at 360° C. for 1 hour to obtain a hydrophobic diffusion layer supported by carbon paper.

Embodiment 3

[0049] Select polyethylene terephthalate synthetic fiber cloth (PET) as the support of the diffusion layer, and the preparation method of the diffusion layer is as follows:

[0050] 1) Pretreatment of the support body:

[0051] Divide 2×2.5cm 2 The organic fiber cloth is soaked in deionized water and ultrasonically oscillated for 30 minutes to remove impurities on the surface.

[0052] 2) Preparation of conductive microporous layer:

[0053] a. Take a certain amount of PVDF resin, add organic solvent DMF, and make a 7% solution;

[0054] b. Put the PVDF solution in a constant temperature water bath at 60°C, and stir continuously for 30 minutes until the PVDF is completely dissolved, and place it for defoaming for later use;

[0055] c. Add the conductive cross-linking material IrO2 / Ti into the PVDF solution, the ratio of IrO2 / Ti to PVDF is 3:1, put it on the stirrer and stir for 30min to make a paste hydrophobic conductive coating;

[0056] d. On the 80°C heating plate, fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com