Infrared optical window and manufacturing method thereof

An infrared optical window, photoresist layer technology, applied in optics, optical components, instruments, etc., can solve the problems of changing the refractive index of the anti-reflection layer, surface unevenness, easy to sink, etc., and achieves insensitivity to changes in the working environment. The method is simple and the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

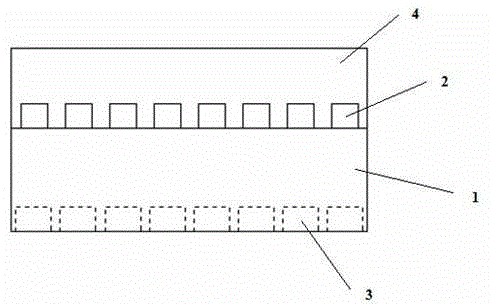

[0021] Such as figure 1 As shown, in the embodiment of the present invention, a method for manufacturing an infrared optical window includes step 10 , step 12 , step 14 and step 16 .

[0022] Step 10: providing an infrared optical window substrate.

[0023] In an embodiment of the present invention, firstly, a substrate for manufacturing an infrared optical window, that is, an infrared optical window substrate is provided. In the embodiment of the present invention, the substrate can be made of any material suitable for manufacturing infrared optical windows, such as silicon, germanium, sapphire, ZnS (zinc sulfide), ZnSe (selenium sulfide), Chalcogenide Glasses (black diamond) etc.

[0024] Step 12: forming a first anti-reflection structure on the incident surface.

[0025] In use, the infrared optical window is incident on one side and exits on the other side, so it has an incident surface and an exit surface. Correspondingly, since the infrared optical window is made bas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com