Nickel-titanium alloy web membrane technology of single hydraulic prop for mine

A single hydraulic prop, nickel-titanium alloy technology, applied in the direction of props/brackets, mining equipment, earthwork drilling and mining, etc., to achieve the effects of environmental protection in production and use, wide application range and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

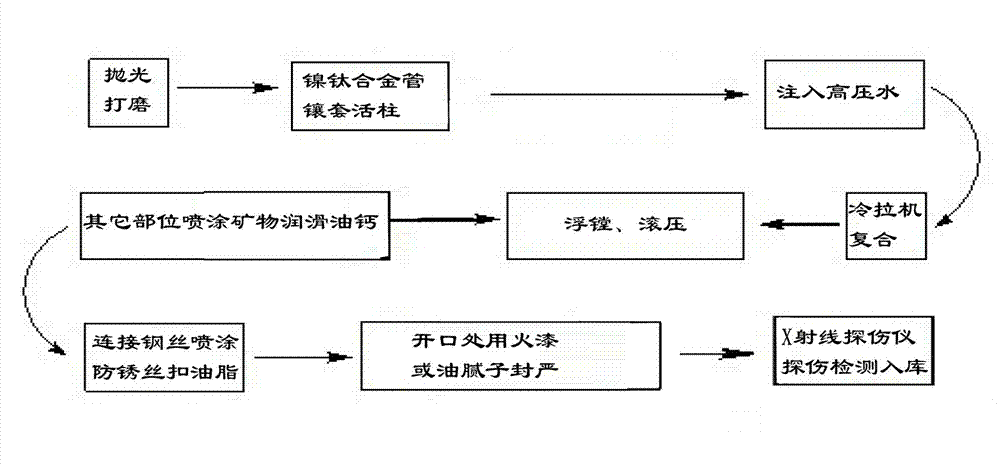

Method used

Image

Examples

Embodiment Construction

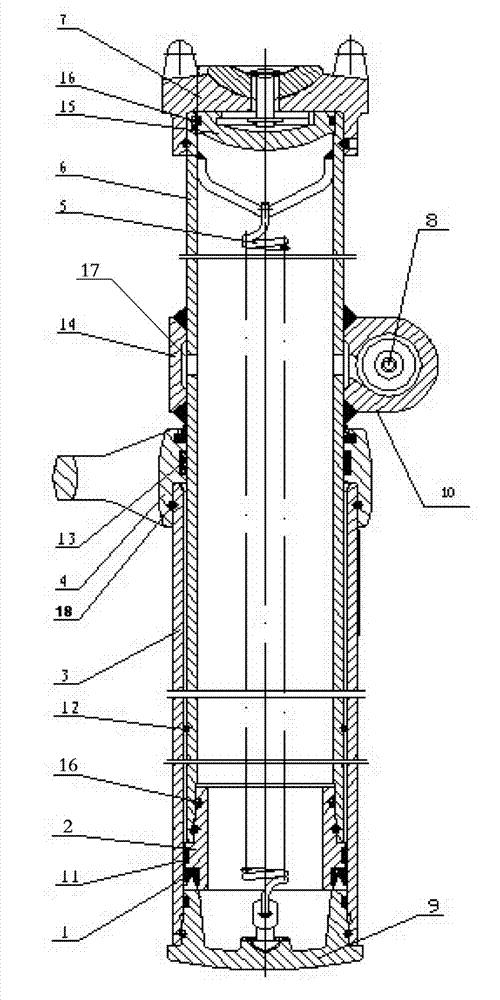

[0029] Below in conjunction with accompanying drawing, structure and technological process of the present invention are described further:

[0030] The nickel-titanium alloy peritoneal technology of mining single hydraulic prop, its structure is mainly composed of: Y-shaped sealing ring 1, piston guide sleeve 11, piston 2, limit steel wire 12, oil cylinder assembly 3, handle body 4, live column guide sleeve 13. Injection valve body 14, return spring 5, live cylinder 6, cover 15, top cover 7, base 9, three-purpose valve 8, etc., wherein piston 2 and live cylinder 6 are arranged inside the cylinder assembly 3 , and the piston 2 is installed on the lower part of the live cylinder 6, the cylinder assembly 3 and the live cylinder 6 are assembled and fixed by the handle body 4 and the casting, the valve seat 10 is welded on the live cylinder 6, and the valve seat 10 is provided with a three-purpose valve 8. A sleeve 17 is fixed outside the movable cylinder 6 in the middle of the han...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com