Anti-seismic lacing bar embedded part

A technology of embedded parts and anti-seismic tension, which is applied in the direction of earthquake resistance, building components, construction, etc. It can solve the problems of scrapped steel holes, scrapped formwork, complex construction operations, etc., to avoid damage, facilitate support and dismantling, and ensure construction quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

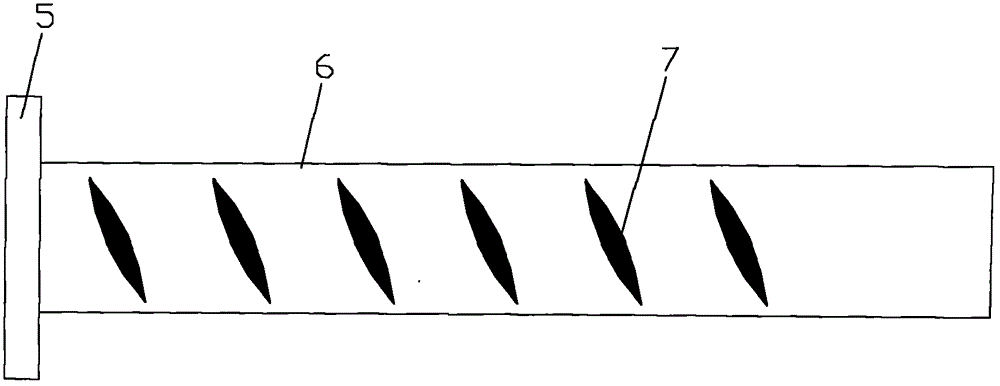

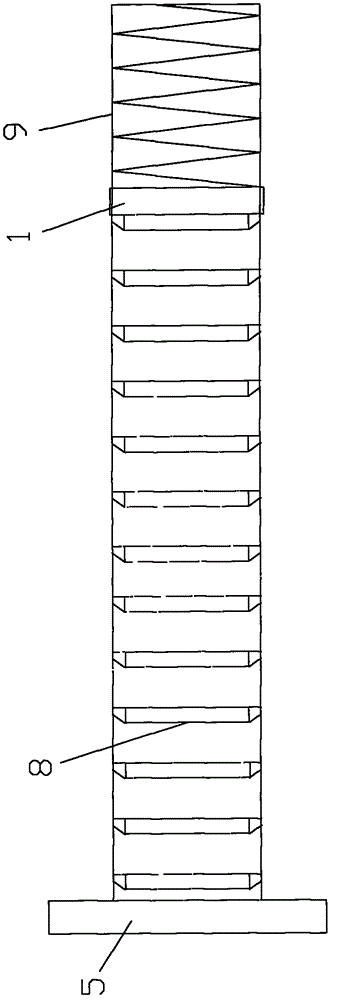

[0024] Such as Figure 1 to Figure 8 As shown, the anti-seismic tie reinforcement embedded part related to the present invention includes a sleeve fixing bracket 10, and the sleeve fixing bracket 10 is connected with the concrete embedded steel bar, and includes a sleeve 6 and a telescopic elastic cap 9. The sleeve 6 is provided with an internal thread 7 or an inverted tooth structure 8; the sleeve 6 is fixed on the sleeve fixing bracket 10, and the stretchable elastic cap 9 is pressed against the pouring concrete formwork.

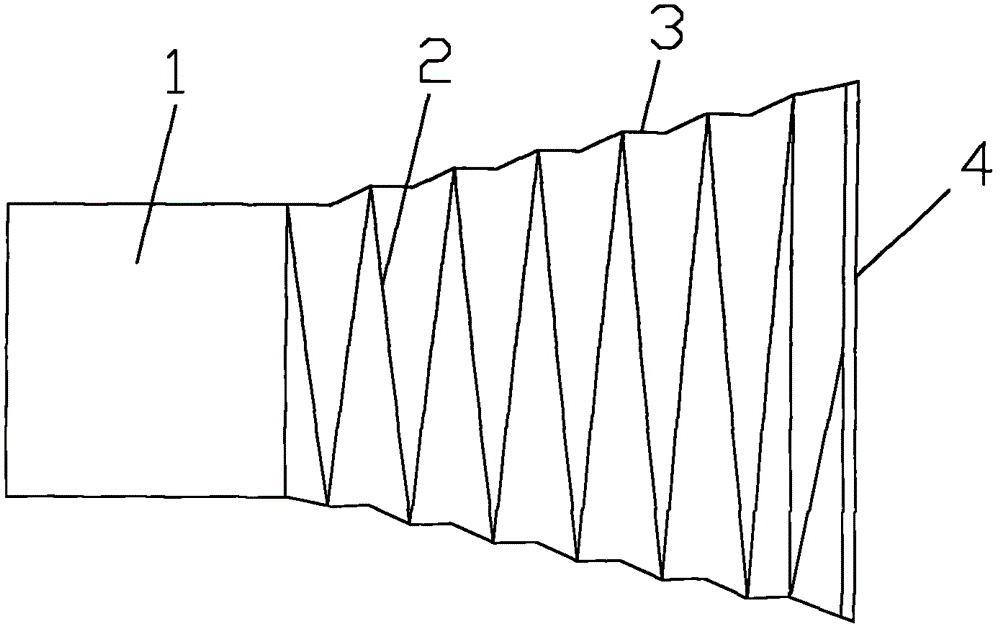

[0025] The flexible elastic cap 9 is columnar or trumpet-shaped, and is composed of a connecting sleeve 1, a shell skin 3, a spring 2 and a cap 4, and the connecting sleeve 1 is connected with the shell skin 3 made of soft material , the spring 2 is arranged in the casing skin 3 , and one end of the spring 2 is pressed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com