Method for producing sheet core material, and sheet core material

A core material and seat technology, applied to seat frames, vehicle seats, chairs, etc., can solve the problems of cost and time increase, and achieve the effect of suppressing excessive deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

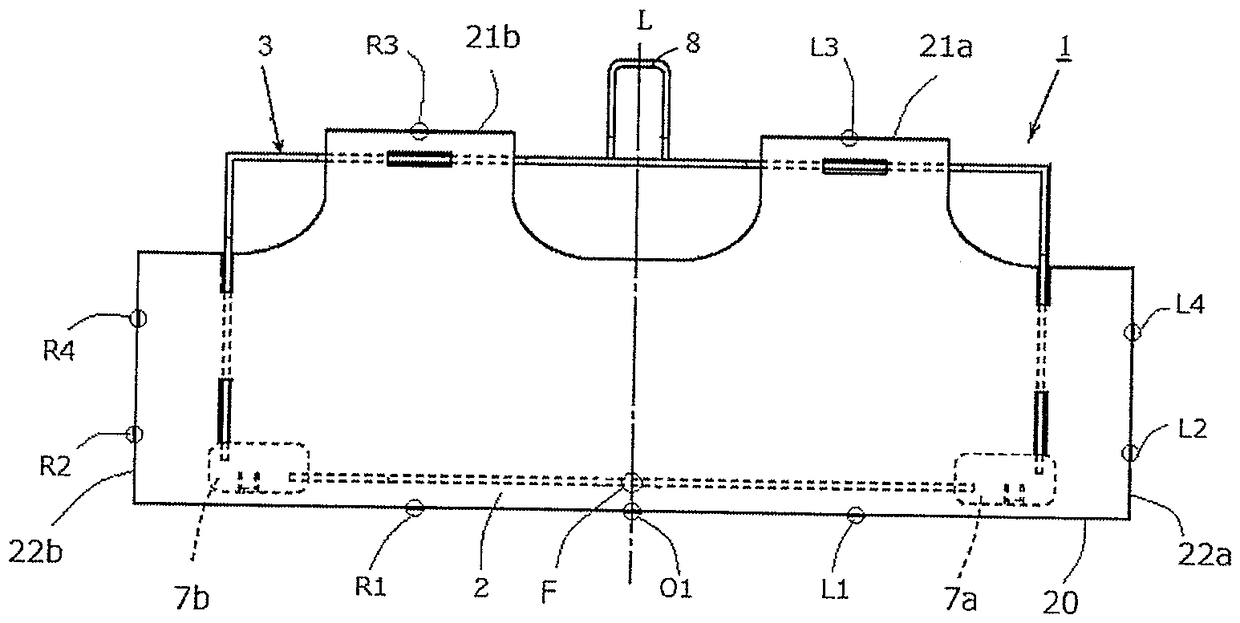

[0098] preparation Figure 1 to Figure 4 The seat core material 1 of the first embodiment shown in FIG.

[0099] (1) Frame parts

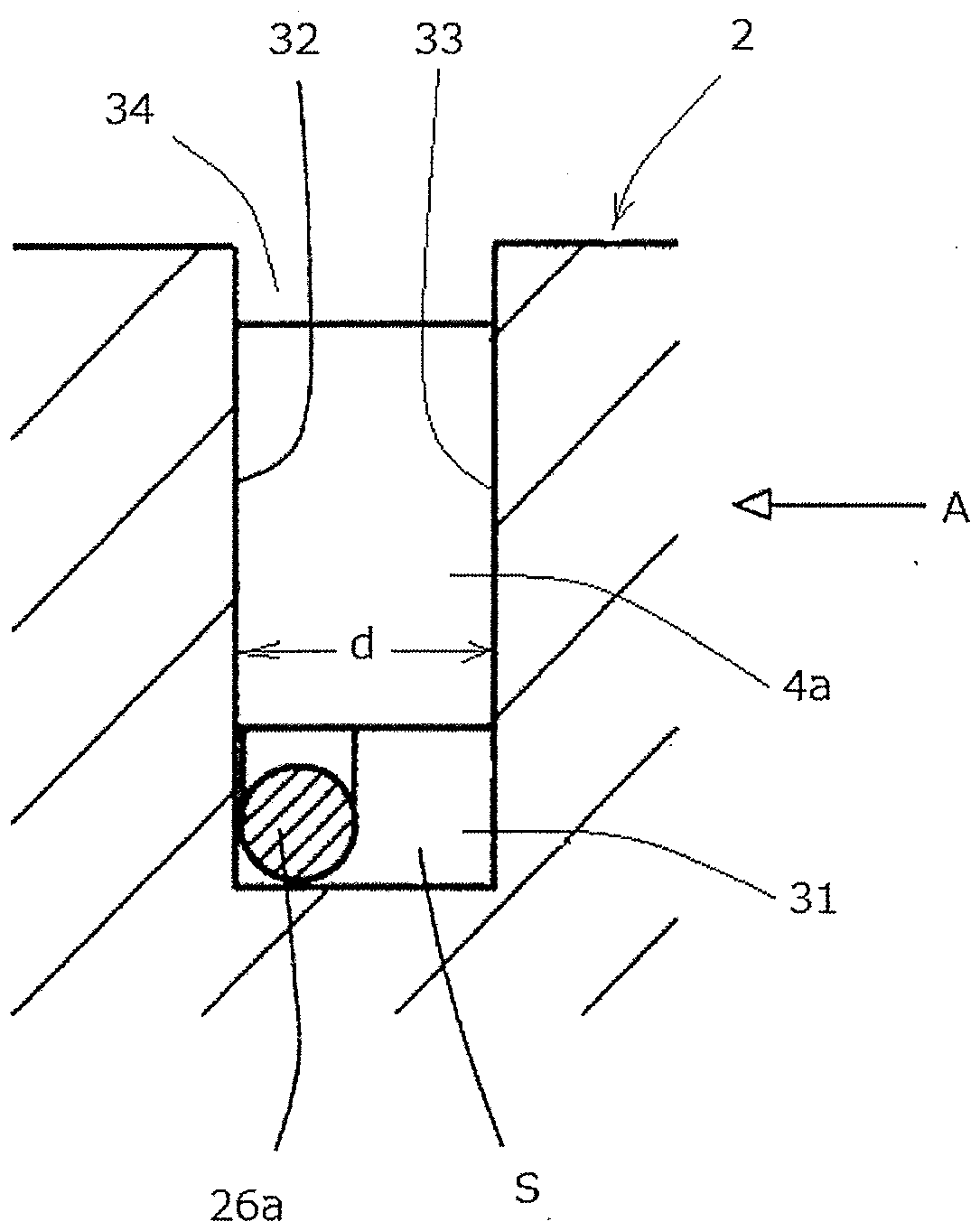

[0100] As the frame member 3, a roughly rectangular wire structure is used. The wire structure has linear wires as the front frame part 24 and U-shaped wires as the rear frame part 25 and the two side frame parts 26a and 26b, which are connected to each other by the two plate parts 7a and 7b. Each wire rod has a diameter of 4.5mm and a tensile strength of 500N / mm² (JIS G3532 SWM-B) and is made of steel. Each of the side frame parts has a length of 400 mm, and the front frame part has a length of 800 mm. Each of the plate portions 7a and 7ab was made of an iron plate having a thickness of 1.2 mm, a longitudinal length of 80 mm, and a transverse length of 170 mm. Hook members 10a and 10b made of the same wire as above are connected to the plate portions 7a and 7b. A coupling protrusion 8 made of the same wire material as above is fixed at the ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com