High-frequency static compaction-drainage-grouting composite foundation processing method and special equipment

A special equipment and static pressure technology, which is applied in basic structure engineering, soil protection, construction, etc., can solve the problems of inability to form medium and shallow hard shells, limited additional stress, excessive post-construction settlement and differential settlement, etc., to achieve Improve the overall vertical bearing capacity and the ability to resist horizontal sideslip, reduce construction costs and shorten the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the technology of the present invention is described in further detail:

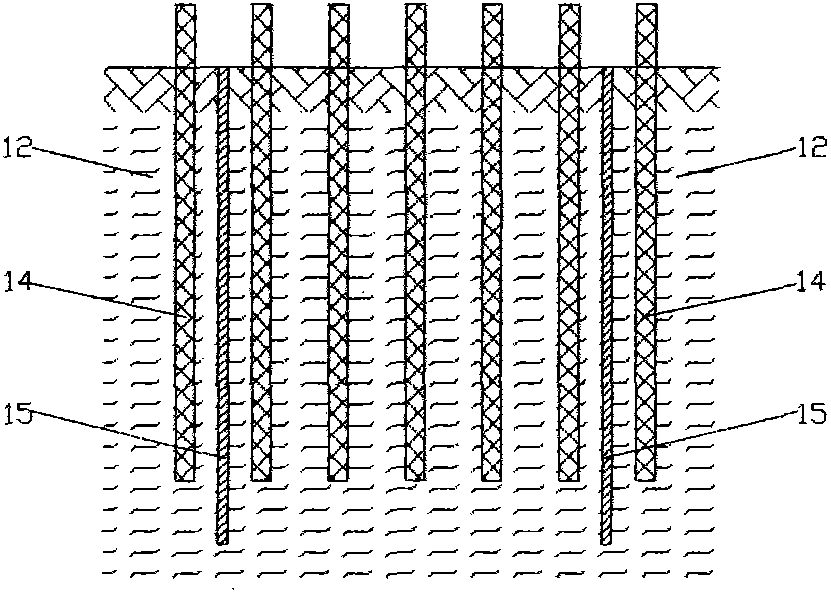

[0024] as attached figure 1 , 2 , 3, shown, what the present invention provides is a kind of first through drainage plate 14 method to improve the bearing capacity of deep soft ground, and then through the medium-deep light tube well 15 The precipitation method improves the bearing capacity of the middle soft foundation, and then passes through the high-frequency hydraulic (electric) static pressure hammer 1 Combined with the static pressure vibrating fixture, the static pressure squeezes the compacted soil plate 5 and steel casing 6 The top is clamped and pressed to make the soft foundation soil 12 compacted rapidly 10 , partially compacted compacted soil 11 Along the steel casing 6 The inner wall pushes the soil upwards 11 And release the excess additional stress energy, and at the same time start the drain 7 The sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com