Artificial composite foundation for building clay core rock-fill dam on deep overburden and construction method for artificial composite foundation

A technology of deep overburden and artificial compounding, which is applied in the direction of dams, barrages, weirs, etc., can solve the problems of large amount of overburden excavation, poor stress and deformation properties of cut-off walls, and breakage of cut-off walls, achieving improvement The coordination of dam body deformation, shortening the construction period, and improving the effect of deformation coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand.

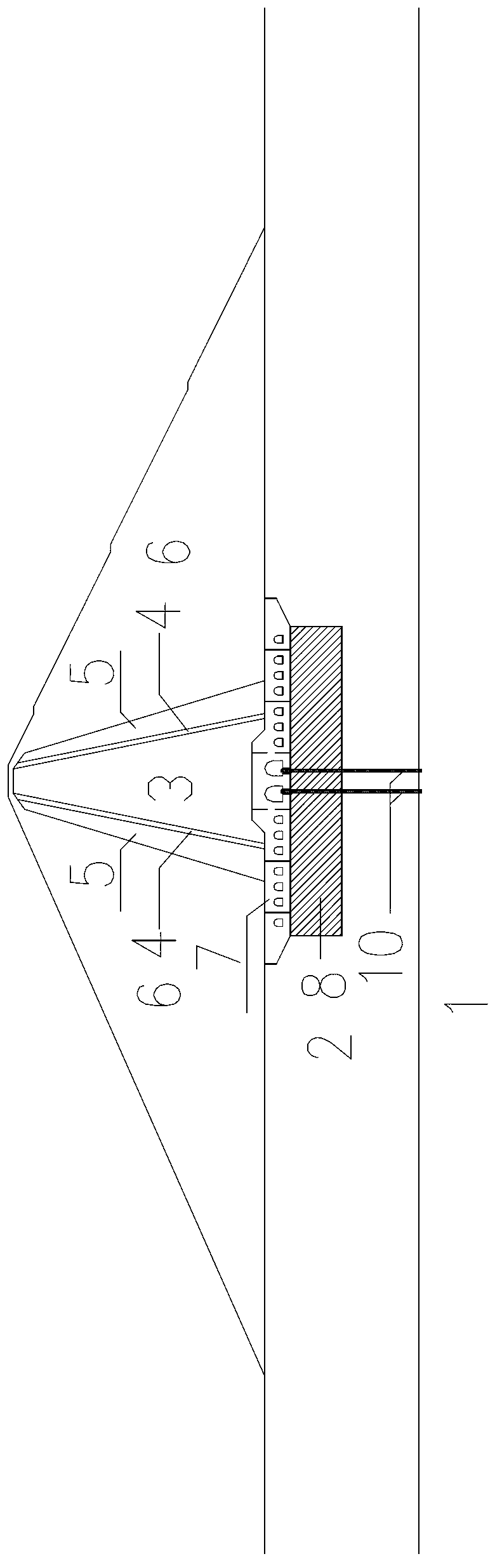

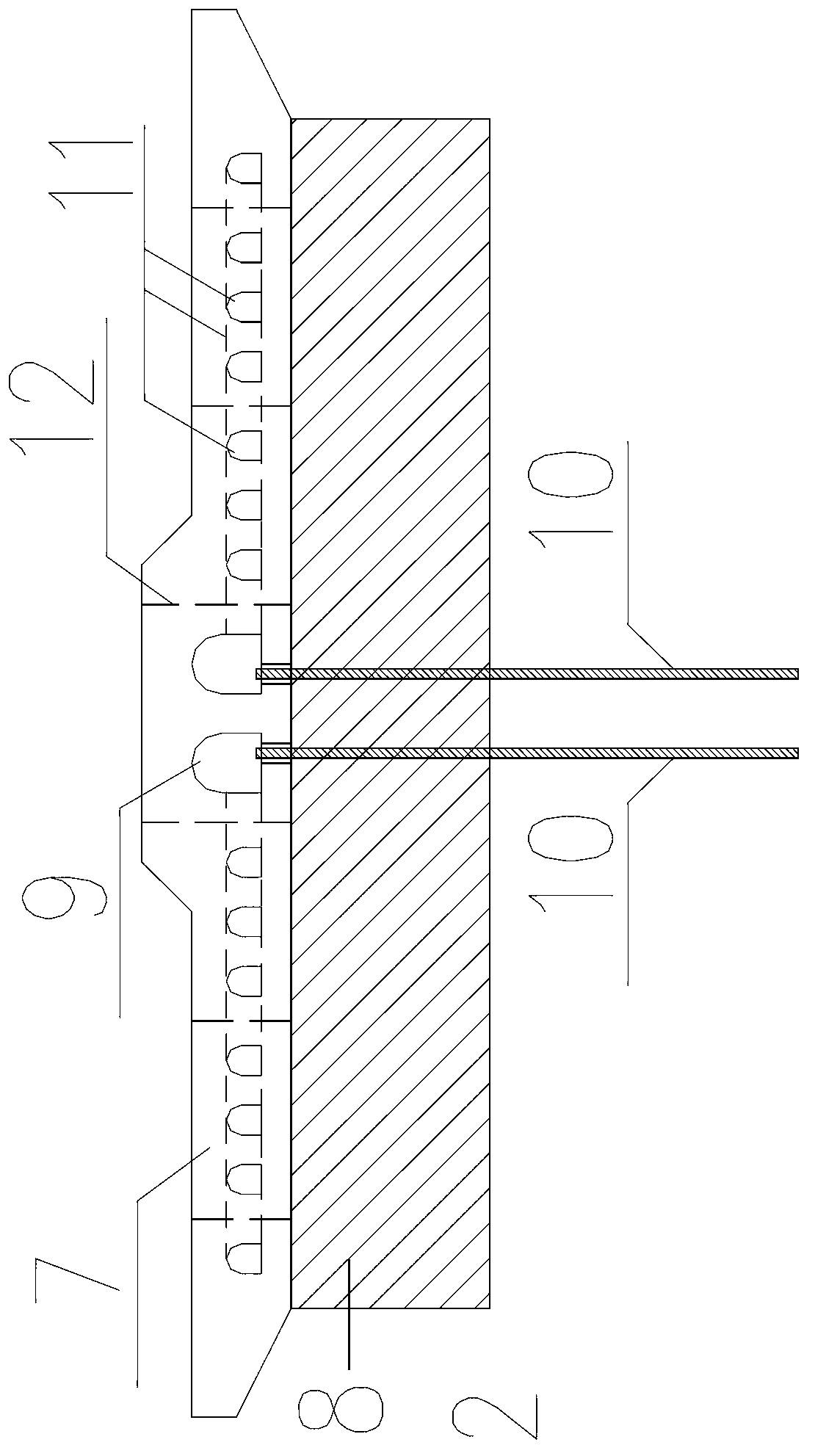

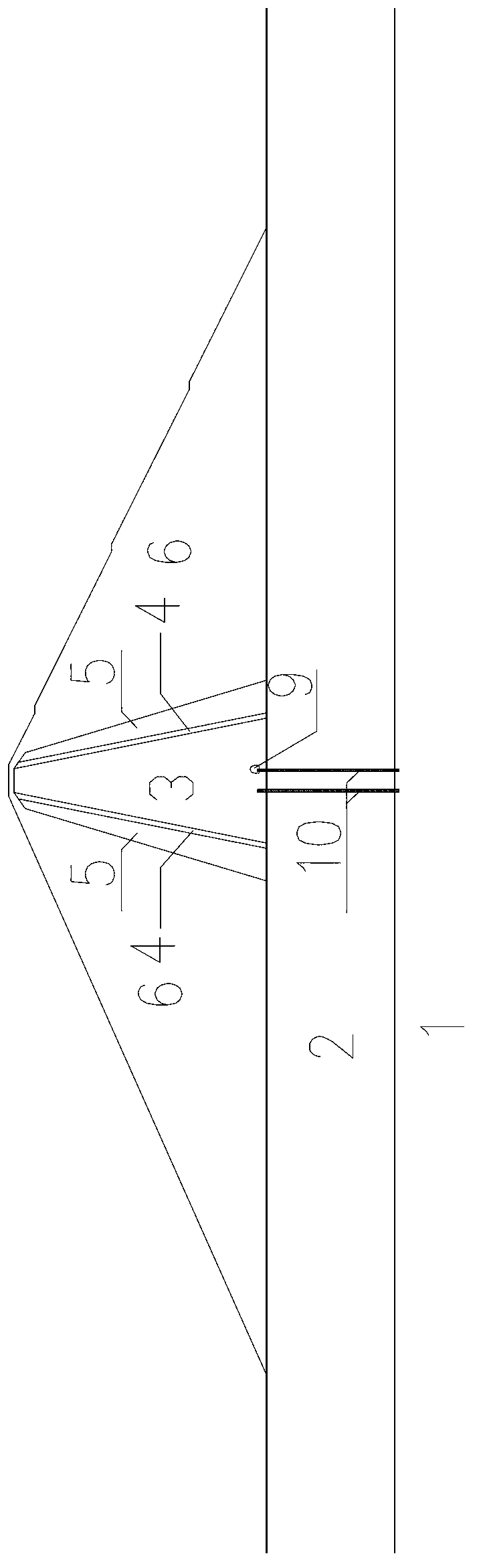

[0036]Referring to the accompanying drawings, it can be seen that: the artificial composite foundation of clay rockfill dam is built on the deep cover layer of the present invention, bedrock 1, cover layer 2 positioned on bedrock 1, core wall 3 positioned on cover layer 2, both sides of core wall 3 It is a reverse filter layer 4, the outside of the reverse filter layer 4 is a filter layer 5, and the outside of the filter layer 5 is a rockfill 6, and the rockfill 6, filter layer 5, reverse filter layer 4, and core wall 3 form a dam body, It is characterized in that the thickness of the covering layer 2 is greater than 50 meters, and there is a concrete cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com