Cement-based sawdust composite noise barrier

A composite sound, cement-based technology, applied in the direction of roads, noise absorption devices, tracks, etc., can solve the problems of time-consuming, high cost, and restricting the application and promotion of cement-based sound-absorbing panels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

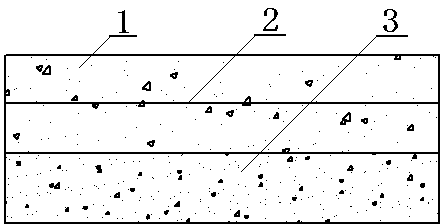

[0022] Embodiment one: from figure 1 It can be seen from the figure that a cement-based wood chip composite sound barrier is composed of a wood chip layer 1 and a concrete layer 3, and the wood chip layer 1 is composed of wood chip particles, glue, cement, water and yellow sand by weight 1:0.048:1.8:4.5 :2.7 ratio for mixing. Then pour it into the mold and pave it, and finally add a certain amount of cement concrete mixture to pave it, press the whole mold under a certain pressure, and release the mold after maintaining the pressure. The thickness of the sawdust layer 1 is 7cm, and the thickness of the concrete layer 3 is 5.5cm; the size of the sawdust particles is 8*4*1mm, and the sawdust particles have been mineralized.

Embodiment 2

[0023] Embodiment 2: A cement-based sawdust composite sound barrier is composed of a sawdust layer 1 and a concrete layer 3, and the sawdust layer 1 is composed of sawdust particles, glue, cement, water and yellow sand in a weight ratio of 1:0.05:2:5: 3 ratio for mixing. Then pour it into the mold and pave it, and finally add a certain amount of cement concrete mixture to pave it, press the whole mold under a certain pressure, and release the mold after maintaining the pressure. The thickness of the sawdust layer is 8cm, and the thickness of the concrete layer 3 is 6cm; the size of the sawdust particles is 10*5*2mm, and the sawdust particles have been mineralized.

Embodiment 3

[0024] Embodiment 3: A cement-based sawdust composite sound barrier, consisting of a sawdust layer 1 and a concrete layer 3, the sawdust layer 1 is composed of sawdust particles, glue, cement, water and yellow sand by weight 1:0.052:2.2:5.5: 3.3 ratio for mixing. Then pour it into the mold and pave it, and finally add a certain amount of cement concrete mixture to pave it, press the whole mold under a certain pressure, and release the mold after maintaining the pressure. The thickness of the sawdust layer 1 is 9cm, and the thickness of the concrete layer 3 is 6.5cm; the size of the sawdust particles is 12*6*3mm, and the sawdust particles have been mineralized.

[0025] In order to improve the strength of the sound barrier, a reinforcement mesh 2 is arranged in the sawdust layer 1 .

[0026] In addition, surface spraying can be carried out according to customer requirements.

[0027] The technical indicators of the cement-based wood chip composite sound barrier are as follows...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com