Environment-friendly cleaning agent for electronic industry

An environmentally friendly technology in the electronics industry, applied in the field of cleaning agents, can solve problems such as death and loss of consciousness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

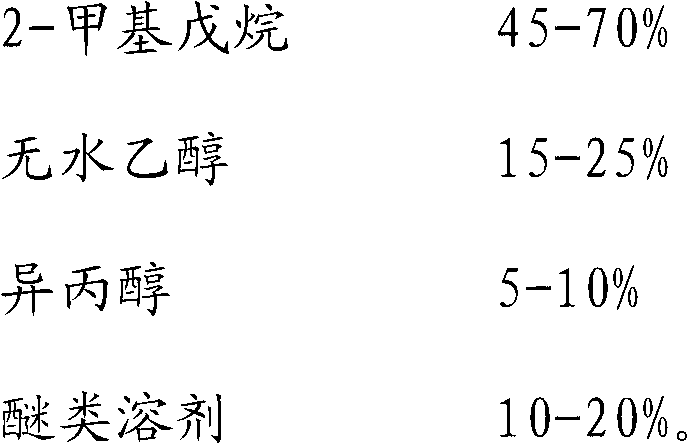

[0019] In the present embodiment, the environment-friendly type cleaning agent for electronic industry is made up of the components of following weight:

[0020]

[0021] The preparation method of the above-mentioned environment-friendly cleaning agent for the electronic industry is as follows: 2-methylpentane, absolute ethanol and isopropanol are added to the reaction kettle according to the above weights in sequence, stirred for 10 minutes, and the stirring speed is 55 rpm, Then add 200g of propylene glycol methyl ether, and then stir for 30 minutes at a stirring speed of 60 rpm to obtain the environment-friendly cleaning agent for the electronics industry of this embodiment.

[0022] Cleaning effect test:

[0023] Test method: Take 10.0g of solder paste (model WTO-LF2000, manufactured by Shenzhen Vitec New Materials Co., Ltd.), place it on a 10×10cm copper sheet, heat and melt it with an electric furnace, and wait until the solder paste is completely melted into a tin bl...

Embodiment 2

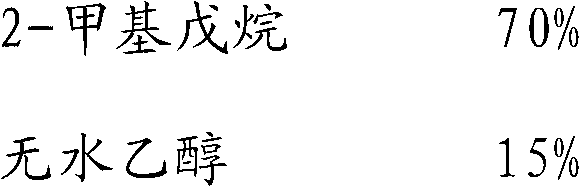

[0027] In the present embodiment, the environment-friendly type cleaning agent for electronic industry is made up of the components of following weight:

[0028]

[0029] The preparation method of the above-mentioned environment-friendly cleaning agent for the electronic industry is as follows: 2-methylpentane, dehydrated alcohol and isopropanol are added to the reaction kettle in sequence according to the above weight, stirred for 15 minutes, and the stirring speed is 50 rpm, Then add 150 g of ethylene glycol monoethyl ether, and then stir for 40 minutes at a stirring speed of 55 rpm to obtain the environment-friendly cleaning agent for the electronics industry of this embodiment.

[0030] The cleaning effect test method of this embodiment is the same as that of Example 1, and its test results are as shown in Table 1.

Embodiment 3

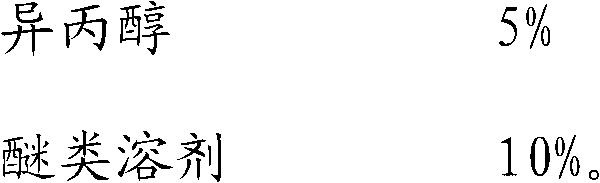

[0032] In the present embodiment, the environment-friendly type cleaning agent for electronic industry is made up of the components of following weight:

[0033]

[0034] The preparation method of the above-mentioned environment-friendly cleaning agent for the electronic industry is as follows: 2-methylpentane, dehydrated alcohol and isopropanol are sequentially added to the reaction kettle according to the above weight, stirred for 10 minutes, and the stirring speed is 65 rpm, Then add 70g of ethylene glycol monoethyl ether and 30g of dipropylene glycol dimethyl ether, and then stir for 35 minutes at a stirring speed of 65 rpm to obtain the environment-friendly cleaning agent for the electronics industry of this embodiment.

[0035] The cleaning effect test method of this embodiment is the same as that of Example 1, and its test results are as shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com