Addition curing type silicone composition and optical element

A silicone composition, addition curing technology, applied in the field of addition curing silicone composition and optical elements, can solve the problem that the transparency, refractive index and elasticity cannot be fully satisfactory, and the performance of optical elements cannot be solved. Satisfactory enough, difficulty in polysiloxane synthesis, etc., to achieve excellent light extraction efficiency, good rubber properties and strength properties, and good strength properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0109] Hereinafter, the present invention will be specifically described by showing production examples, examples, and comparative examples, but the present invention is not limited to the following examples.

[0110] In addition, in the following examples, the viscosity means the value measured at 23 degreeC using a rotational viscometer.

[0111] The refractive index refers to the refractive index at 589 nm measured at 25°C using a digital refractometer RX-5000 manufactured by Japan Atago Co., Ltd. (ATAGO CO., LTD.). The hardness, elongation at break and tensile strength are Measured according to JIS-K6249.

[0112] The light transmittance is the transmittance to light having a wavelength of 400 nm measured at 25° C. using a spectrophotometer about a cured product obtained by forming the composition into a thin plate with a thickness of 2 mm and curing it.

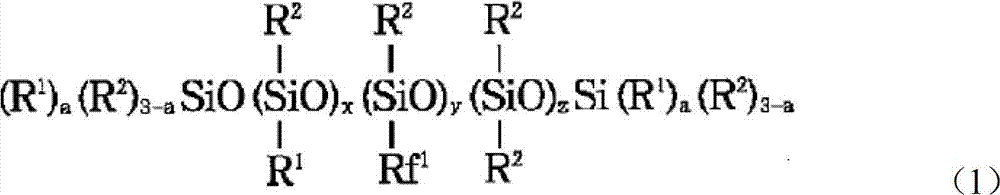

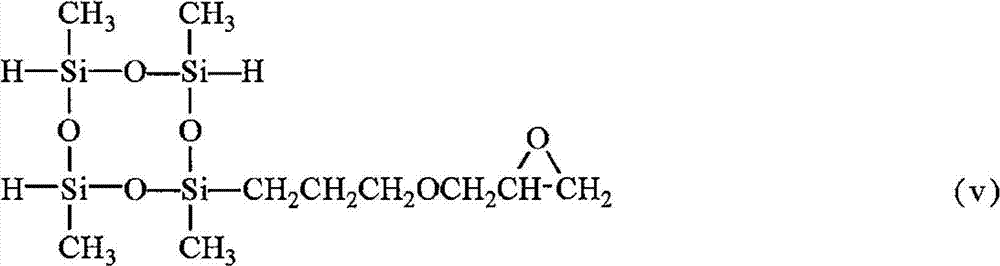

[0113] In addition, in the following examples, the symbols representing the average composition of the linear organop...

preparation example 1

[0124] [Preparation Example 1] Preparation of platinum catalyst (catalyst A)

[0125] The reaction product of chloroplatinic acid and sym-tetramethyldivinyldisiloxane was diluted with toluene so that the platinum content was 1.0% by mass, thereby preparing the platinum catalyst (catalyst A) used in the present example and the comparative example. .

preparation example 2

[0126] [Preparation Example 2] Synthesized from D Vi / T F1 Organopolysiloxane with branched structure represented by =2 / 8

[0127] 160 g of hexafluoro-m-xylene, 290 g of water and 323 g of concentrated hydrochloric acid were added to a 2 L flask, and the temperature was raised to 70° C. while stirring. After the temperature was raised, 175 g (0.8 mol) of trifluoropropyltrimethoxysilane, 26 g (0.2 mol) of methylvinyldimethoxysilane, and 40 g of hexafluorom-xylene were added dropwise. After dripping, it aged at 75 degreeC for 2 hours. After aging, the hydrochloric acid water in the upper layer was removed, and then the organic layer was washed with water, and the washing was repeated until the washed water became neutral. 0.1 g of potassium hydroxide was added to the washed organic layer, the temperature was raised to 120° C., and a dehydration condensation reaction was performed. After the completion of the reaction, 1 g of potassium acetate and 0.23 g of trimethylchlorosil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com