Printing and dyeing wastewater processing method

A treatment method and technology for printing and dyeing wastewater, which can be applied in textile industry wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., and can solve problems such as poor biodegradability, high concentration of pollutants, and unsatisfactory effects , to achieve the effect of low treatment cost and less sludge output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

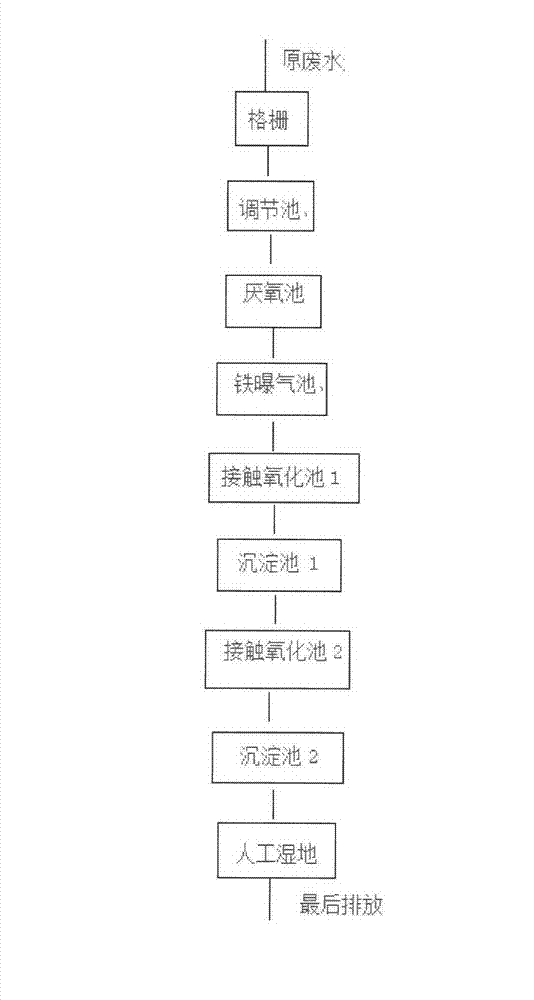

[0010] Such as figure 1 Shown, a kind of processing method of printing and dyeing wastewater of the present invention comprises the steps:

[0011] The raw wastewater is passed through the grid, regulating tank, anaerobic tank, iron aeration tank, contact oxidation tank 1, sedimentation tank 1, contact oxidation tank 2, sedimentation tank 2, artificial wetland, and finally discharged. Among them, the sludge generated in the iron aeration tank, contact oxidation tank and sedimentation tank flows back into the anaerobic tank for internal digestion.

[0012] The following is a detailed description of the various processes mentioned above in conjunction with the implementation

[0013] (1) Grille. Before the waste water enters the treatment system, the coarse impurities in the waste water should be separated by grille to protect the treatment facilities from damage and avoid pipeline blockage.

[0014] (2) Regulating pool. Due to the high discharge concentration, complex compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com