Cyclic utilization method of wastewater from casein phosphoeptide production

A technology of casein phosphopeptide and protein phosphopeptide, which is applied in chemical instruments and methods, food industry wastewater treatment, adsorption water/sewage treatment, etc. It can solve the problems that wastewater cannot be recycled and protein cannot be effectively recovered, and achieve additional economy Good benefits, wide range of product applications, and the effect of reducing processing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

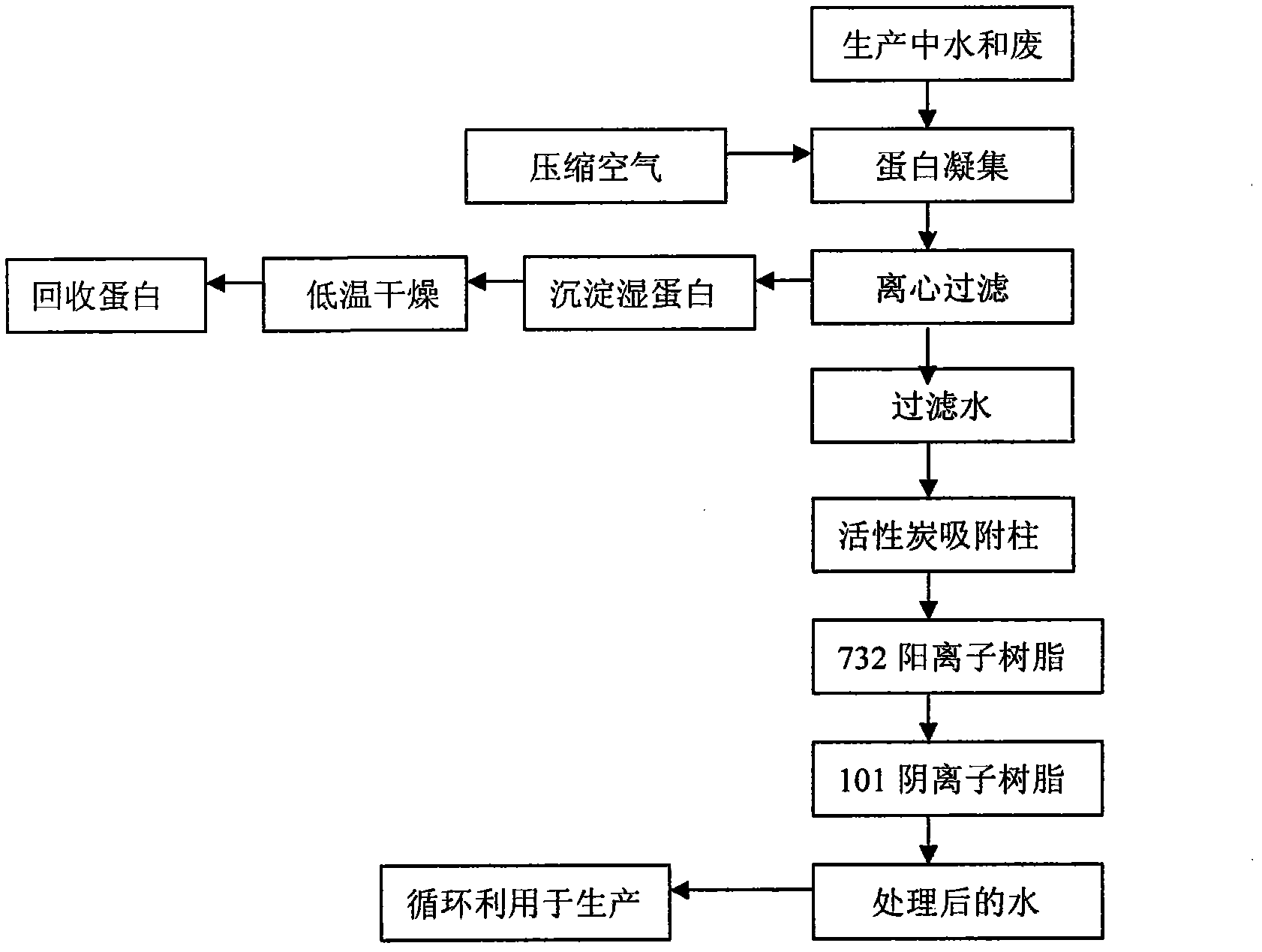

Image

Examples

Embodiment 1

[0028] A method for recycling waste water in the production of casein phosphopeptides, the steps of which are divided into:

[0029] a. Wastewater protein precipitation in casein phosphopeptide production

[0030] The proportion of waste water in the production of casein phosphopeptide is 1.010kg / L, the solid content is 1.156% (w / w), and the pH is 4.0-5.0. Add 5000ml of waste water to a 10000ml capped stainless steel container, pass compressed air at a rate of 1.5L / min at room temperature for 30min, and then let it stand for 30min to allow the protein gel to fully coagulate and precipitate, and the precipitated protein is centrifuged at 5000rmp, The recovered precipitated protein was vacuum-dried at 65° C. and 120 mmHg to obtain 2.8 g of recovered protein.

[0031] b. Wastewater ultrafiltration membrane filtration

[0032] After recovering the protein, the wastewater with a pH of 4.45, a specific gravity of 1.034kg / L, and a volume of 4825ml is filtered by roll membrane ultra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com