Method for treating urban domestic sewage based on magnetic nanomaterial reinforced activated sludge

A technology for urban domestic sewage and activated sludge, which is applied in water/sludge/sewage treatment, biological water/sewage treatment, chemical instruments and methods, etc. High cost, complex management and other problems, to achieve the effect of excellent physical adsorption and flocculation capacity, low cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

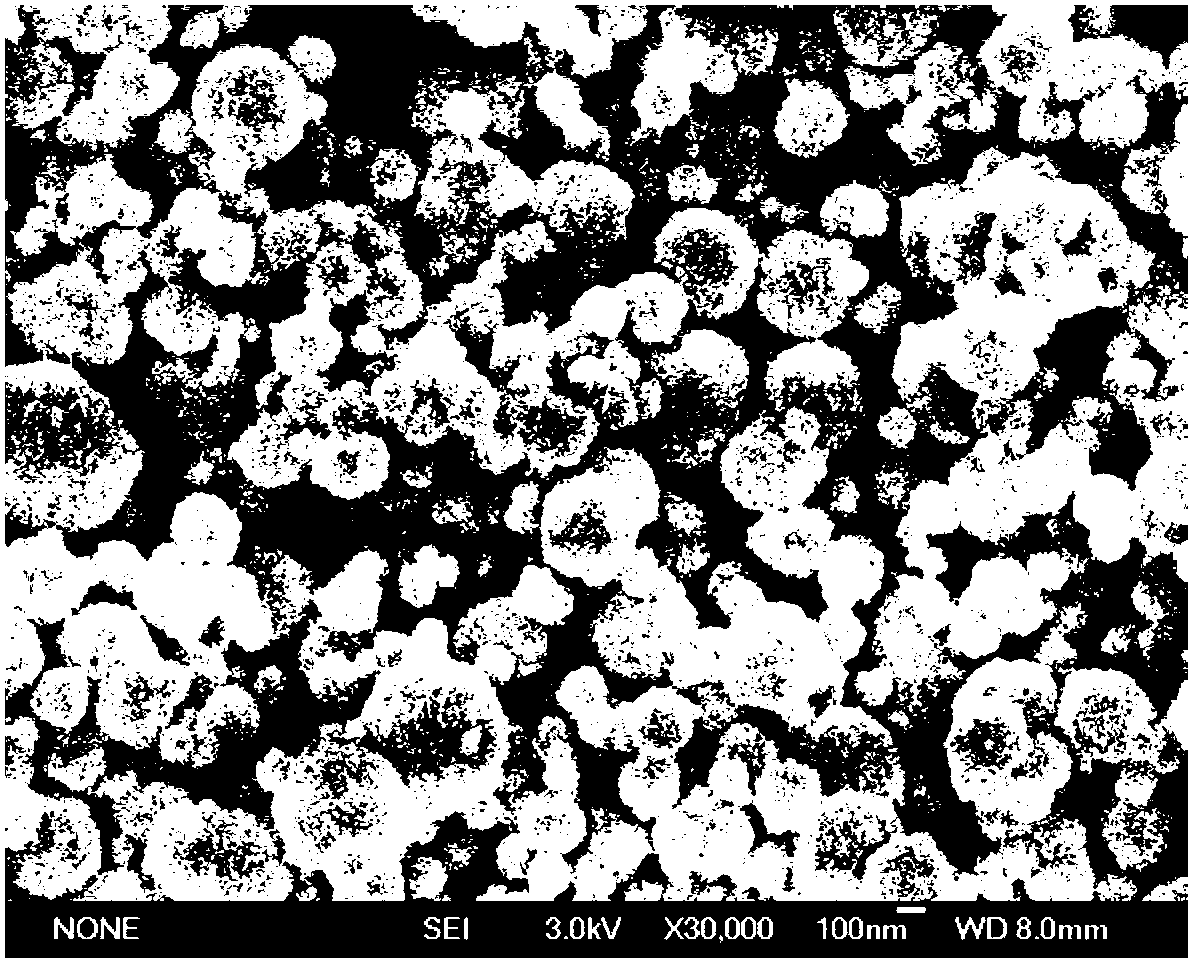

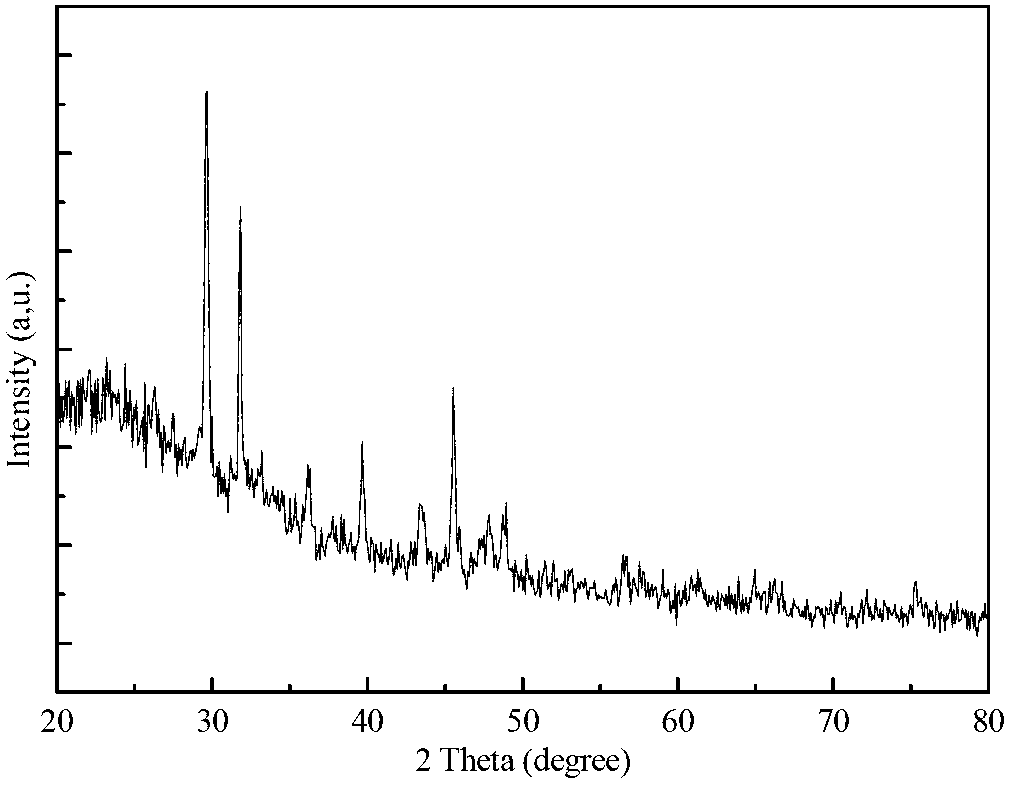

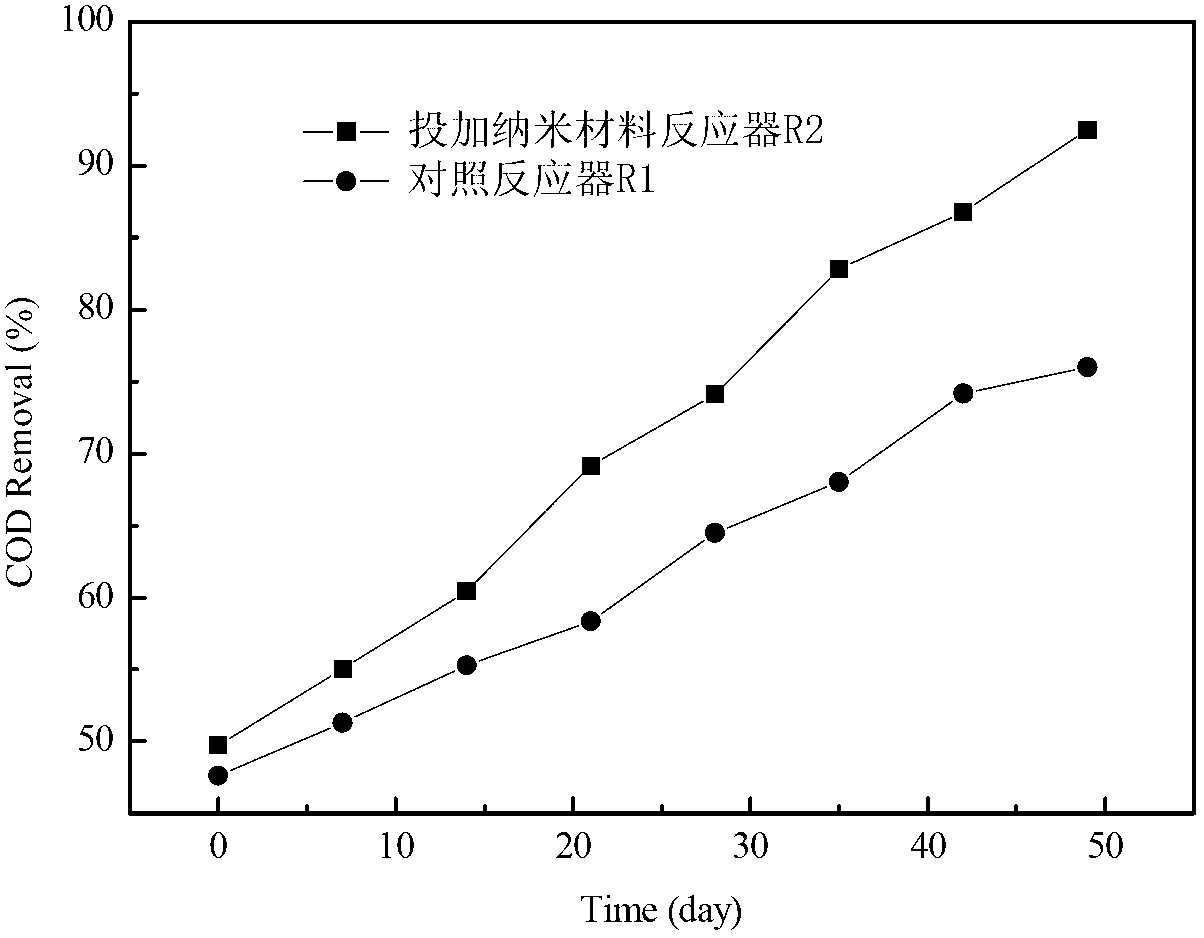

[0042] (1) Take FeCl 3 Dissolve 6.5g and 2.0g of sodium citrate in 200mL of ethylene glycol, then add 10.0g of sodium acetate while stirring, stir for 30 minutes, then seal it in a 500mL Teflon-lined reactor and heat to 200°C, After continuing for 10 hours, cool to room temperature, take out the reactants, rinse with ethanol and deionized water for 3 times, dry and sieve to obtain particles with a particle size of 80-400nm, that is, MN magnetic nanomaterials. Scanning electron microscope photos as figure 1 As shown, the appearance of the obtained material is circular and nanoscale; the XRD spectrum is as follows figure 2 As shown, the main components of MN magnetic nanomaterials are iron and oxygen, and iron mainly exists in the form of ferric iron; the obtained MN magnetic nanomaterials are used for the sewage treatment in the next step.

[0043] (2) Take 20L of urban domestic wastewater from the sewage treatment plant every day and add it to the R2 reactor. The pollutant...

Embodiment 2

[0049] (1) Take FeCl 3 Dissolve 7.5g and 2.0g of sodium citrate in 200mL of ethylene glycol, then add 11.0g of sodium acetate while stirring, stir for 30 minutes, then seal it in a Teflon-lined reactor, heat to 220°C, and continue After 10h, cool to room temperature, take out the reactant, and wash with ethanol and deionized water several times to obtain MN magnetic nanomaterial particles;

[0050] (2) Take 20L of domestic wastewater from the sewage treatment plant every day and add it to the reactor. Add 0.1g / (L·week) MN magnetic nanomaterial particles to the solution at room temperature; use an air compressor to aerate and maintain at 0.1m 3 / h, the HRT is 12 hours at room temperature, and the efficiency of pollutants in wastewater is improved. After the completion of the reaction, it was tested and calculated that the removal rate of COD in the R2 reactor finally reached more than 95%, and the removal rate of R1 was relatively low.

[0051] In order to have a better con...

Embodiment 3

[0053] (1) Take FeCl 3 Dissolve 6.5g and 2.2g of sodium citrate in 240mL of ethylene glycol, then add 12.0g of sodium acetate while stirring, stir for 30 minutes, then seal it in a polytetrafluoroethylene-lined reactor, heat to 180°C, and continue After 12 hours, cool to room temperature, take out the reactant, and wash with ethanol and deionized water several times to obtain MN magnetic nanomaterial particles;

[0054] (2) Take 20L of domestic wastewater from the sewage treatment plant every day and add it to the reactor. Add 0.12g / (L·week)MN magnetic nanomaterial particles into the solution at room temperature; use an air compressor to aerate to maintain at 0.1m 3 / h, the HRT is 6 hours at room temperature, and the efficiency of pollutants in wastewater is improved. After the reaction, it was tested and calculated that the removal rate of COD in the R2 reactor finally reached more than 89%, which was higher than the removal rate of R1.

[0055] In order to have a better ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com