Mesoporous-macroporous multilevel ordered monodisperse micron sphere and preparation method thereof

A technology of monodispersion and microspheres, applied in the field of materials, can solve the problems of poor monodispersity of particles, unsuitable for chromatographic packing, large size, etc., and achieve the effect of uniform size, easy to obtain raw materials, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

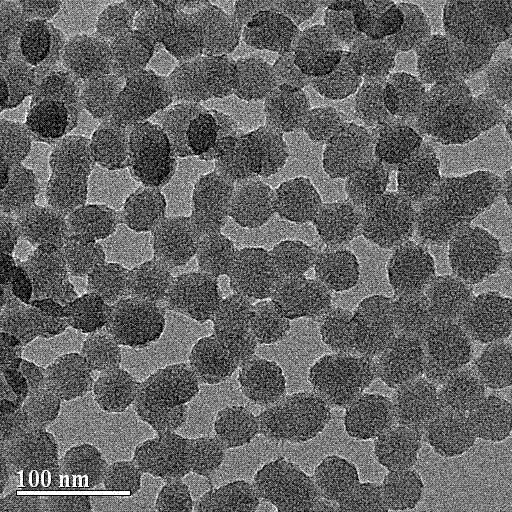

[0025] Example 1 Preparation of nano-mesoporous materials

[0026] Mix 64 mL of water, 10.5 mL of ethanol, and 10.4 mL of 25 wt% cetyltrimethylammonium chloride aqueous solution at room temperature and stir for 10 min. Then, in this solution, 4.1 mL of triethanolamine was added, and further stirred until all the triethanolamine was dissolved.

[0027] Take 20 mL of the above solution, heat it to 60°C, and add 1.5 mL of tetraethyl orthosilicate dropwise to the solution while stirring, the dropping time is controlled within 2-3 min, and the stirring is continued for 10 min after the dropwise addition is completed.

[0028] The sample prepared by the above method was centrifuged, the supernatant was discarded, and the precipitate was immediately dispersed in deionized water, sonicated for 1 min, and washed twice.

[0029] Disperse 0.1 g of the sample in 10 mL of template removal solution (1 mL of concentrated hydrochloric acid + 9 mL of ethanol). After ultrasonic treatment for...

Embodiment 2

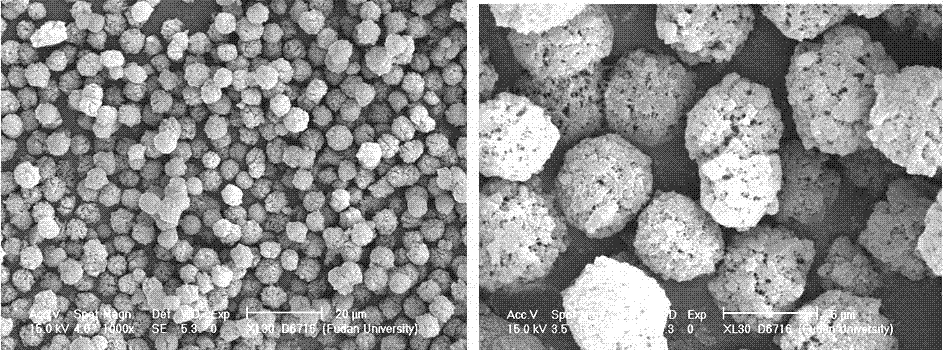

[0030] Example 2 urea-formaldehyde / SiO 2 Synthesis of Composite Microspheres

[0031]The nano-mesoporous material obtained above was dispersed in 10 mL of distilled water to obtain a colloidal solution of nano-mesoporous particles, and the pH of the solution was adjusted to 2 with 1 M HCl. Add 10% (v / v) absolute ethanol, add 3 g of urea under constant stirring, and then add 6 g of formaldehyde aqueous solution after it is completely dissolved, stir rapidly for 5 min, stop stirring and keep at 15 °C React for 1 h. Then add a large amount of water and stir quickly to terminate the reaction, pour the mixed solution into a large beaker and let it stand, and the composite microspheres will settle at the bottom of the beaker. After the obtained precipitate was washed with ethanol and water twice, ethyl acetate was used to remove water azeotropically. The scanning electron microscope image of the obtained material is shown in figure 2 .

Embodiment 3

[0032] Example 3 Synthesis of Mesoporous-Macroporous Hierarchical Ordered Microspheres

[0033] Synthesis of mesoporous-macroporous hierarchically ordered microspheres: The composite microspheres obtained in the previous step were vacuum-dried at 160°C for 1 h, and then calcined in a nitrogen atmosphere by temperature programming in a muffle furnace. The setting procedure of the muffle furnace is as follows: from room temperature to 180 °C for 180 min, from 180 °C to 240 °C for 300 min, at 240 °C for 60 min, at 240 °C to 260 °C for 120 min, and at 260 °C for 60 min, 260 °C It takes 120 minutes from ℃ to 300℃, 300 minutes from 300℃ to 600℃, and 180 minutes at 600℃. The scanning electron microscope image of the obtained material is shown in image 3 with Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com