Inorganic binder containing phosphorus and aluminum compounds

A technology of inorganic binders and aluminum compounds, applied in molecular sieve catalysts, chemical/physical processes, catalyst activation/preparation, etc., can solve the problems of solidification of reactants and low activity of cracking catalysts, and achieve increased feeding speed and wear resistance Proximity, the effect of high propylene content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

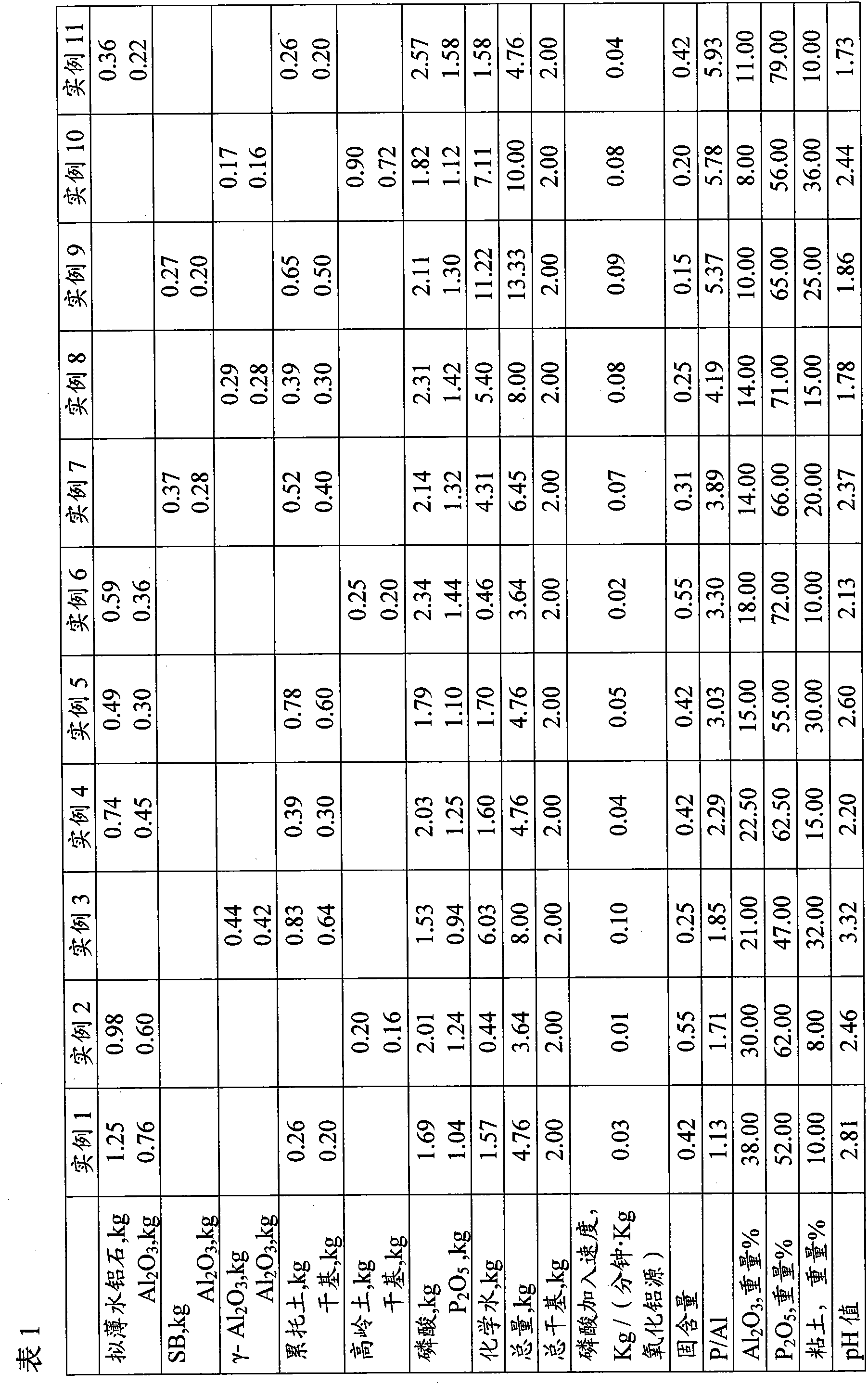

[0035] This example prepares the inorganic binder of the phosphorus-containing aluminum compound provided by the present invention.

[0036] At room temperature (25°C), 1.25 kg of pseudo-boehmite (containing Al 2 o 30.76 kg), 0.26 kg of retort soil (0.20 kg on a dry basis) mixed with 1.57 kg of decationized water, beat for 30 minutes, add 1.69 kg of concentrated phosphoric acid (mass concentration 85%) to the slurry under stirring, and the addition rate of phosphoric acid is 0.03Kg Phosphoric acid / min / Kg alumina source, heat up to 70°C, and then react at this temperature for 45 minutes to prepare an inorganic binder containing phosphorus-aluminum compounds. The material ratio is shown in Table 1.

Embodiment 2~11

[0038] Examples 2-11 illustrate the preparation of the inorganic binder containing phosphorus-aluminum compound provided by the present invention.

[0039] At room temperature (25°C), mix alumina source (aluminum hydroxide or aluminum oxide), clay (rectorite or kaolin) and decationized water, beat for 30 minutes, add concentrated phosphoric acid (mass concentration 85 %), and then reacted at a temperature of 70° C. for 45 minutes to obtain an inorganic binder containing phosphorus-aluminum compounds. See Table 1 for materials, their proportions and preparation conditions.

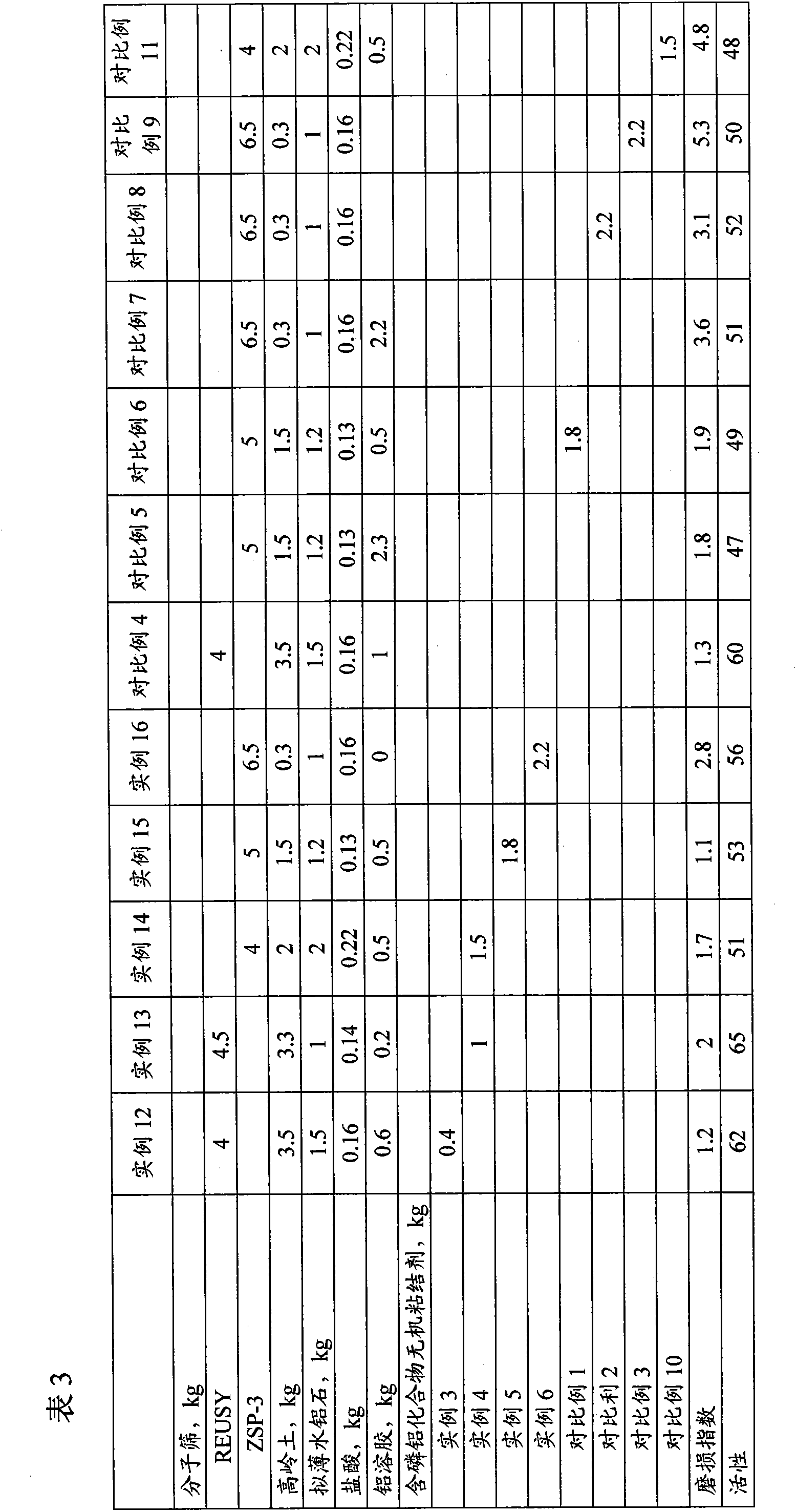

Embodiment 12

[0049] This example illustrates the preparation of a zeolite cracking catalyst using the phosphorus-aluminum inorganic binder provided by the invention.

[0050] 4 kg (dry basis) rare earth ultra-stable Y-type zeolite is added to 8 kg of water to make rare-earth ultra-stable Y-type zeolite slurry, then add 3.5 kg (dry basis) kaolin and 1.5 kg (based on dry basis) in the zeolite slurry Alumina meter) pseudoboehmite, beating for 60 minutes, adding 0.16 kg of hydrochloric acid (concentration 36% by weight), beating for 20 minutes, to obtain slurry, its pH value is 3.1, then adding the phosphorus-containing aluminum prepared in Example 3 0.4 kg of inorganic binder was beaten for 10 minutes, then 0.6 kg of aluminum sol was added, beaten for 30 minutes, spray-dried, and calcined at 600°C for 2 hours to obtain a cracking catalyst. The feed ratio and wear index of the catalyst are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com