Assembly type biomass briquette fuel steam boiler

A molding fuel and steam boiler technology, which is applied to water tube steam boilers, steam boilers, boiler water pipes, etc., can solve the problems of difficult installation of partition wall bricks, heavy structures, complex structures, etc., to facilitate ignition and combustion, and increase air flow Disturbance, effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

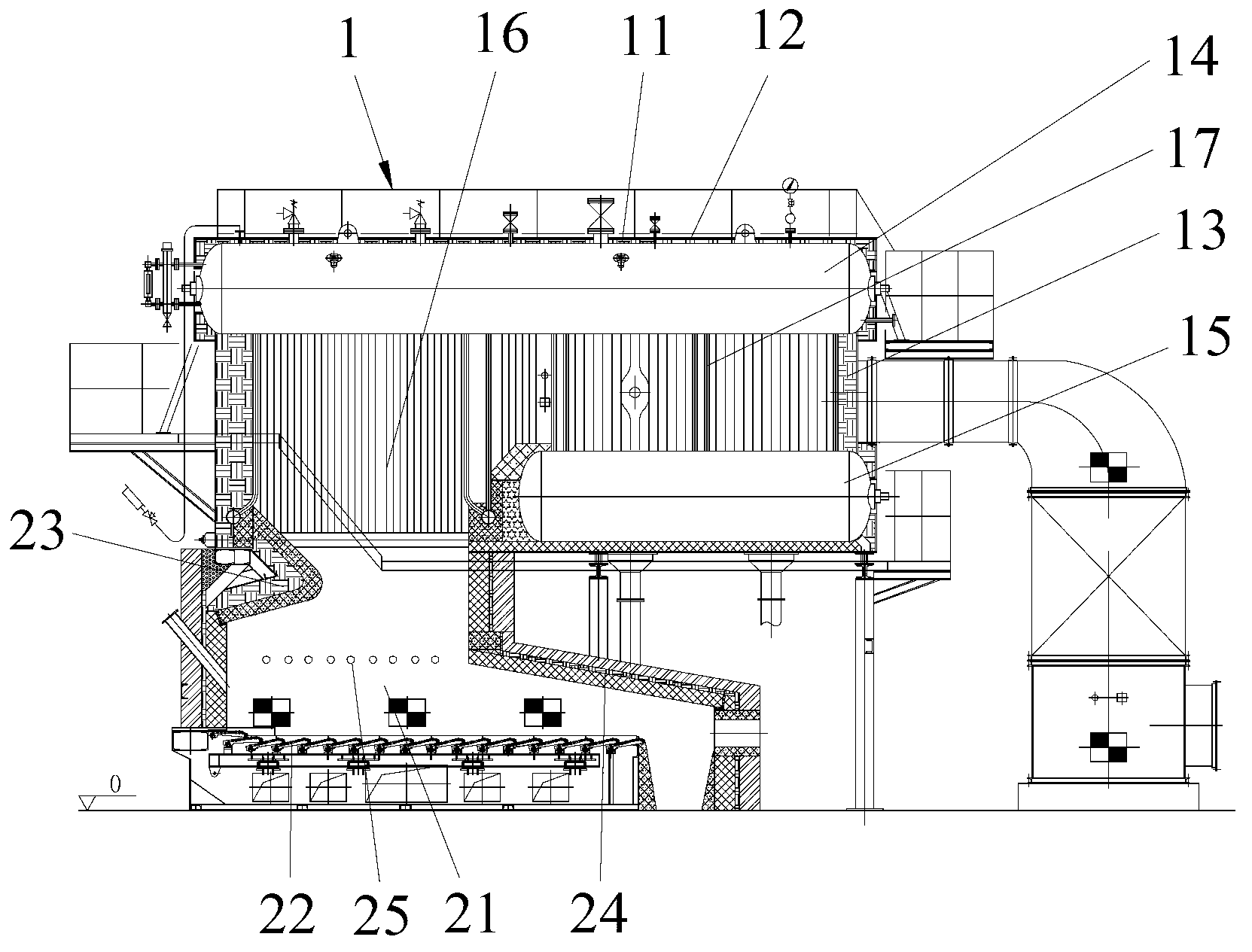

[0028] Please refer to Figure 2-4 , the assembled biomass briquette fuel steam boiler includes a boiler body 1 and a combustion device 2 located below the boiler body 1 .

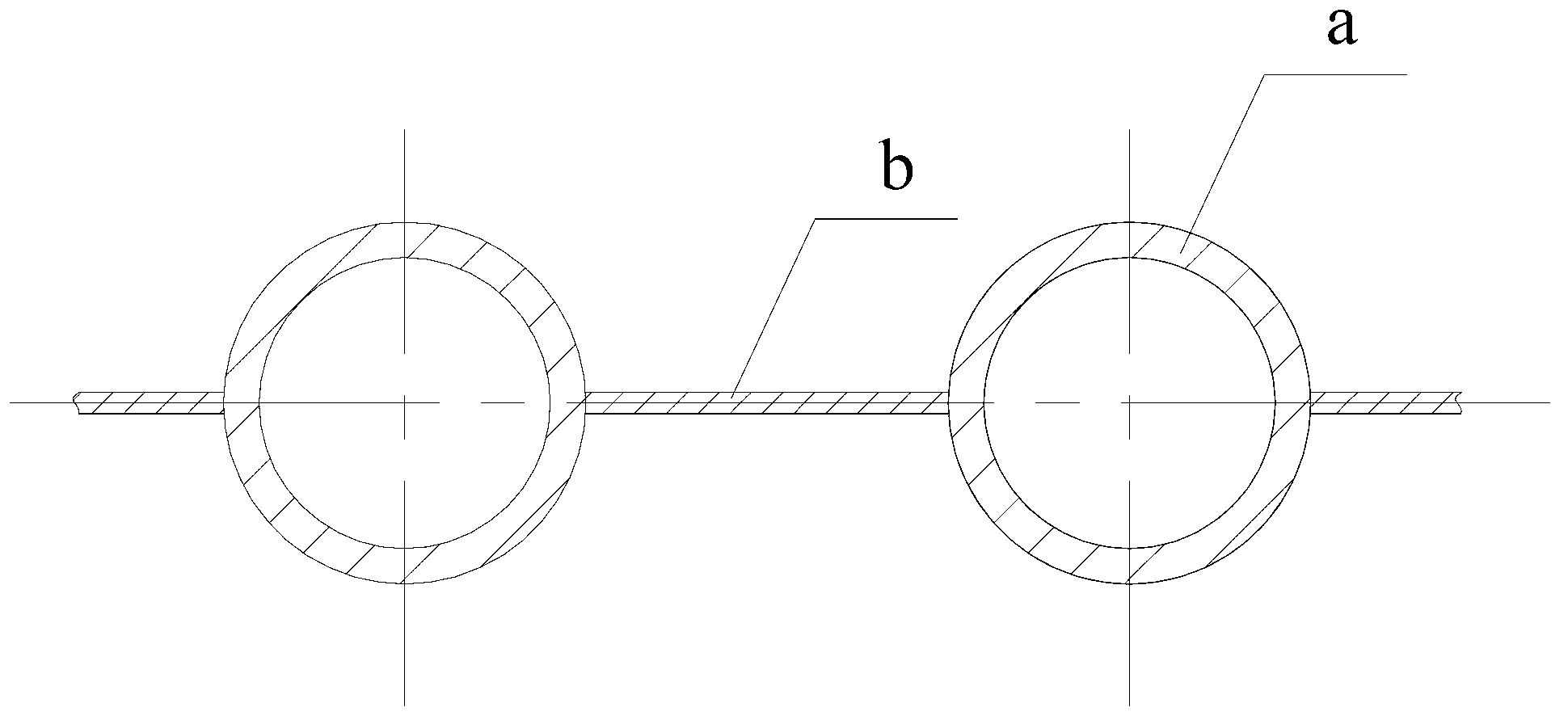

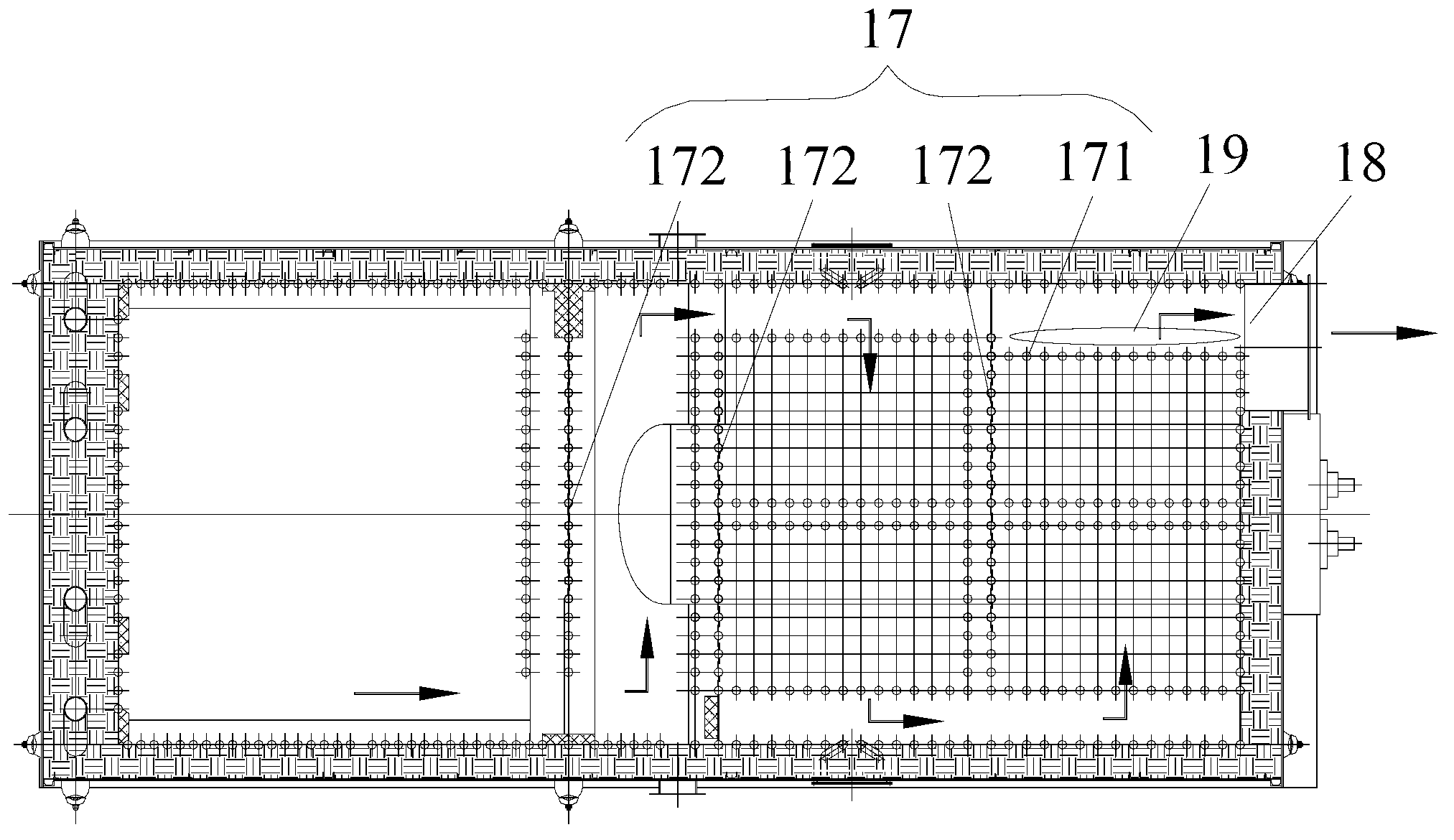

[0029] The boiler body 1 includes a bracket 11 , a shell 12 , a furnace wall 13 , an upper drum 14 , a lower drum 15 , a membrane wall 16 and a convection tube bundle 17 . The convection tube bundle 17 is located inside the membrane wall 16, the membrane wall 16 is located between the upper and lower drums 14, 15, and the furnace wall 13 is wrapped around the membrane wall 16 and the membrane wall 16. The upper and lower drums 14 and 15 are outside, the shell 12 is wrapped on the outside of the furnace wall 13 , and the bracket 11 is arranged inside the shell 12 . The bracket 11, the casing 12, the furnace wall 13, the upper drum 14, the lower drum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com