Preparation method of high-strength and high-conductivity copper alloy

A copper alloy and high-conductivity technology, applied in the field of non-ferrous metal processing, can solve the problems of reducing the electrical conductivity of the alloy, and it is difficult to obtain high-strength and high-conductivity copper alloys at the same time, to achieve increased strength, good industrial application prospects, and good electrical conductivity. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

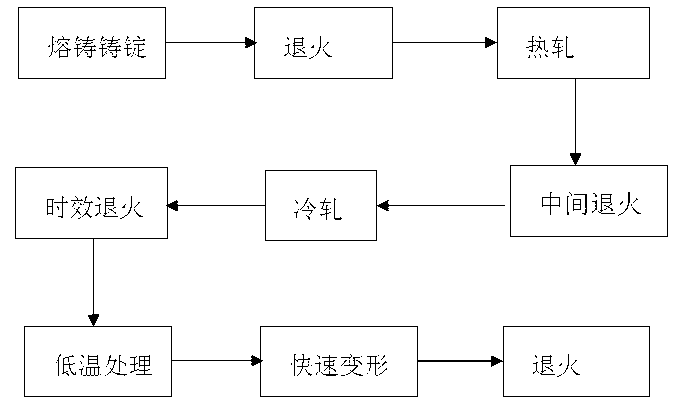

[0028] Chromium-zirconium-copper alloy (the composition of chromium Cr 0.5-1.0%, zirconium Zr 0.2-1.0%, lanthanum La 0.1-0.4%, magnesium Mg and other impurity elements figure 1 shown.

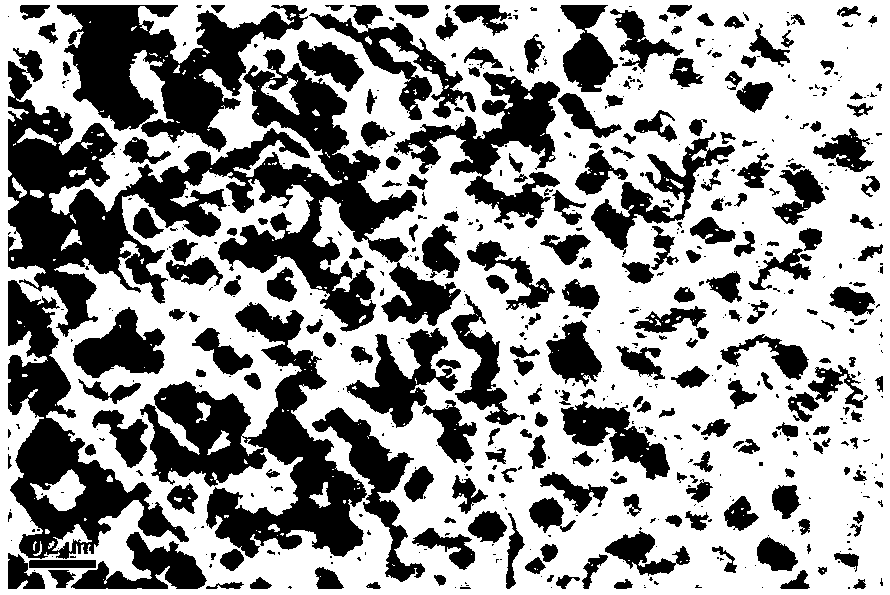

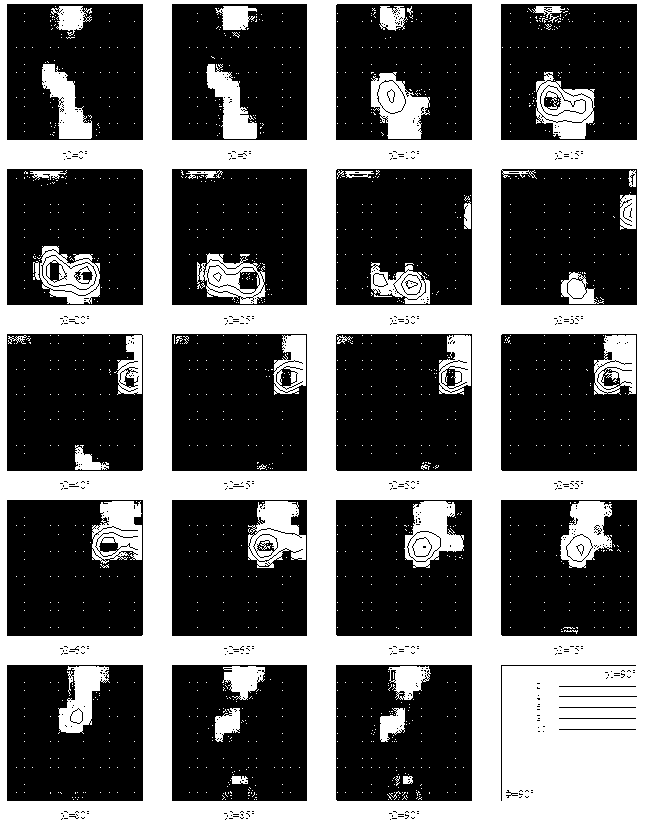

[0029] Finally, a high-strength and high-conductivity copper alloy sample is obtained, and the microstructure of the sample is as follows: figure 2 As shown, many dispersed fine grains are formed, the texture type of the sample is {110} type texture, and the Φ cross-sectional view of the spatial orientation distribution of the high-strength and high-conductivity copper alloy crystal is shown in image 3 shown. The tensile strength of the obtained sample is 610MPa, the elongation is 16%, and the electrical conductivity is 83%IACS. For the performance comparison of the obtained samples under different temperature and deformation conditions, see Figure 7 shown.

Embodiment 2

[0031] Chromium-zirconium-copper alloy (the composition of chromium Cr 0.5-1.0%, zirconium Zr 0.2-1.0%, lanthanum La 0.1-0.4%, magnesium Mg and other impurity elements figure 1 shown.

[0032] Finally, a high-strength and high-conductivity copper alloy sample was obtained. The texture type of the obtained sample was {100} texture. Figure 4 shown. The tensile strength of the obtained sample is 635MPa, the elongation is 13%, and the electrical conductivity is 81%IACS. For the performance comparison of the obtained samples under different temperature and deformation conditions, see Figure 7 shown.

Embodiment 3

[0034] Chromium-zirconium-copper alloy (the composition of chromium Cr 0.5-1.0%, zirconium Zr 0.2-1.0%, lanthanum La 0.1-0.4%, magnesium Mg and other impurity elements figure 1 shown.

[0035] Finally, a high-strength and high-conductivity copper alloy sample was obtained, Figure 5 Shown is the EBSD orientation imaging map of high-strength and high-conductivity copper alloy crystals. The tensile strength of the obtained sample is 615MPa, the elongation is 15%, and the electrical conductivity is 87%IACS. For the performance comparison of the obtained samples under different temperature and deformation conditions, see Figure 7 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com