Process for preparing agricultural ammonium potassium sulfate from biotite powder

A technology of biotite powder and potassium ammonium sulfate, applied in the direction of ammonium sulfate, alkali metal sulfite/sulfite, application, etc., can solve the problems of complex process and high energy consumption, and achieve simple process and high utilization rate of raw materials High and mild reaction conditions

Inactive Publication Date: 2012-12-26

昊青薪材(北京)技术有限公司

View PDF2 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the main ways to make potassium fertilizer from biotite at home and abroad are: to make calcium magnesium potassium fertilizer and potassium chloride, etc. The main disadvantages are complicated process and high energy consumption

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0016] Example: The raw material of biotite powder is a by-product from the beneficiation and processing of phosphate rock in a certain place in Qinghai.

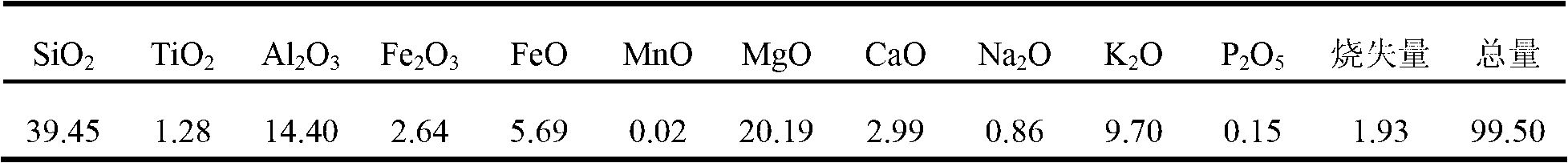

[0017] Table 1 Analysis results of chemical composition of biotite powder in a certain place in Qinghai B %

[0018]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

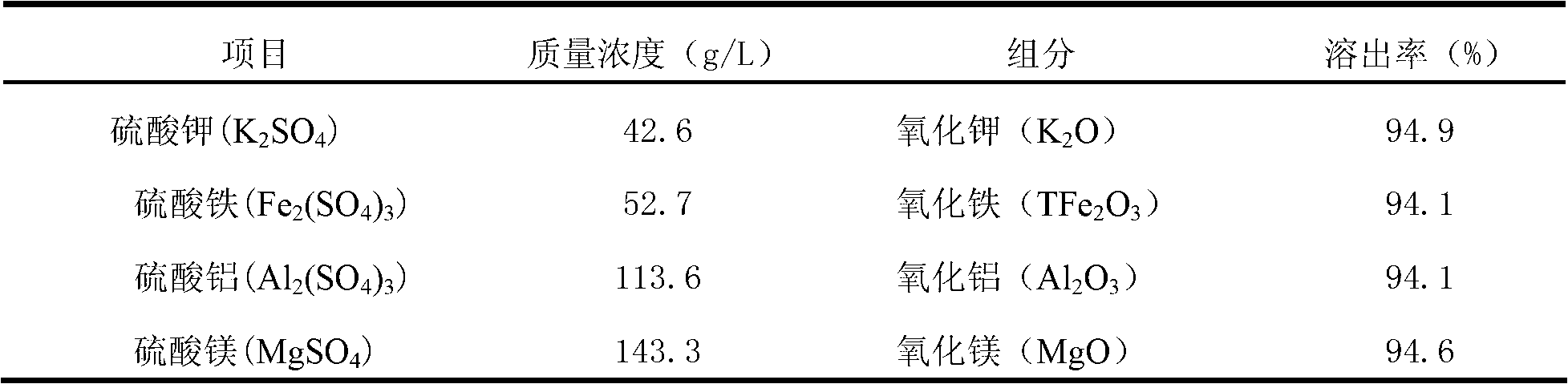

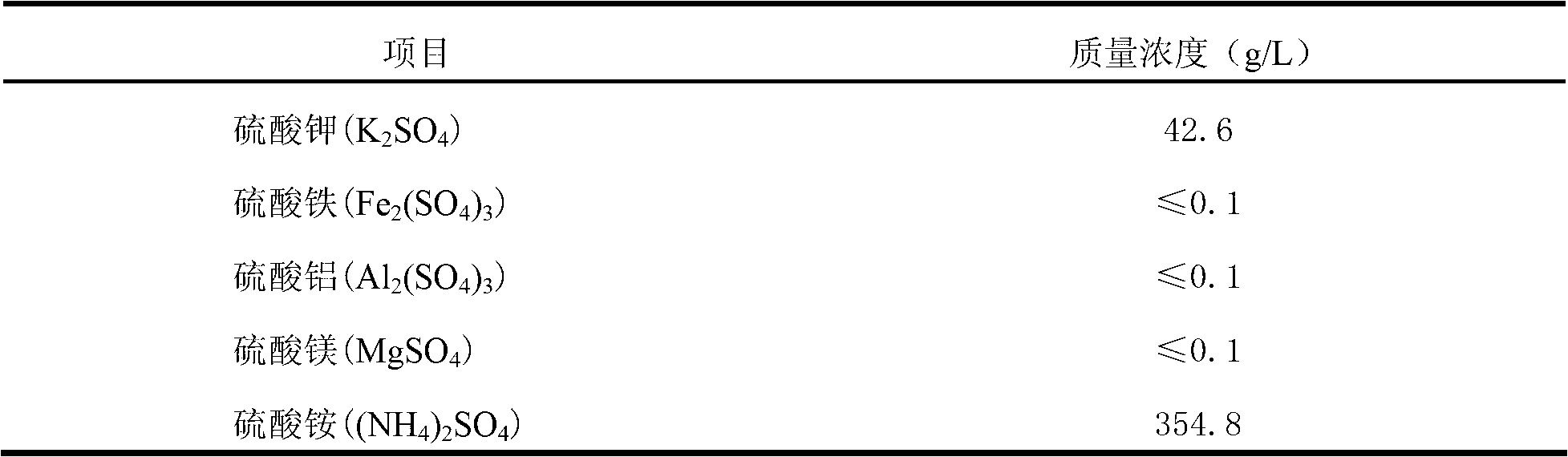

The invention discloses a process for preparing agricultural ammonium potassium sulfate from biotite powder. The process includes mixing biotite powder, water and sulfuric acid; controlling reaction condition to achieve dissolution rate of potassium oxide in the biotite of above 94 wt%; filtering to collect filtrate containing potassium sulfate, magnesium sulfate, aluminum sulfate and ferric sulfate; introducing ammonia gas into the filtrate to precipitate out ferric hydroxide, aluminum hydroxide and magnesium hydroxide; filtering to collect filtrate containing potassium sulfate and ammonium sulfate, for preparing agricultural ammonium potassium sulfate product; utilizing the ferric hydroxide, aluminum hydroxide and magnesium hydroxide for preparation of iron oxide red, aluminum hydroxide and magnesia respectively; and utilizing the filter cake (amorphous colloidal metasilicic acid) for preparation of inorganic silicide products. The process has the advantages of simple process, mild reaction condition, low cost, and high material utilization rate.

Description

technical field [0001] The invention relates to a process for preparing agricultural ammonium potassium sulfate by using biotite powder as raw material. Background technique [0002] Potassium ammonium sulfate is a common chlorine-free crop fertilizer in the world. It can provide three nutrients of potassium, nitrogen and sulfur to crops at the same time, which can not only increase crop yield, but also improve its quality. It can be used in sulfur-deficient soil to improve crop resistance disease ability. At present, the methods for producing potassium sulfate in my country mainly include: Mannheim method, Glauber's salt method, gypsum method and ammonium sulfate method. The raw material used in the invention is biotite, a natural mineral resource, which belongs to layered silicate minerals. In the biotite lattice, potassium ions are located between the layers, and its potassium oxide content is usually 8% to 10% by weight. At present, the domestic and foreign ways of us...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C01D5/00C01C1/24C01G49/02C01F5/20C01F7/34C01B33/14C05C3/00

Inventor 罗征林斐马鸿文

Owner 昊青薪材(北京)技术有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com