Full-automatic flexible plate bending machine

A fully automatic, bending machine technology, applied in the field of bending machines, can solve the problems of uncontrollable angle, low precision, low efficiency, etc., and achieve the effect of convenient operation, small size and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

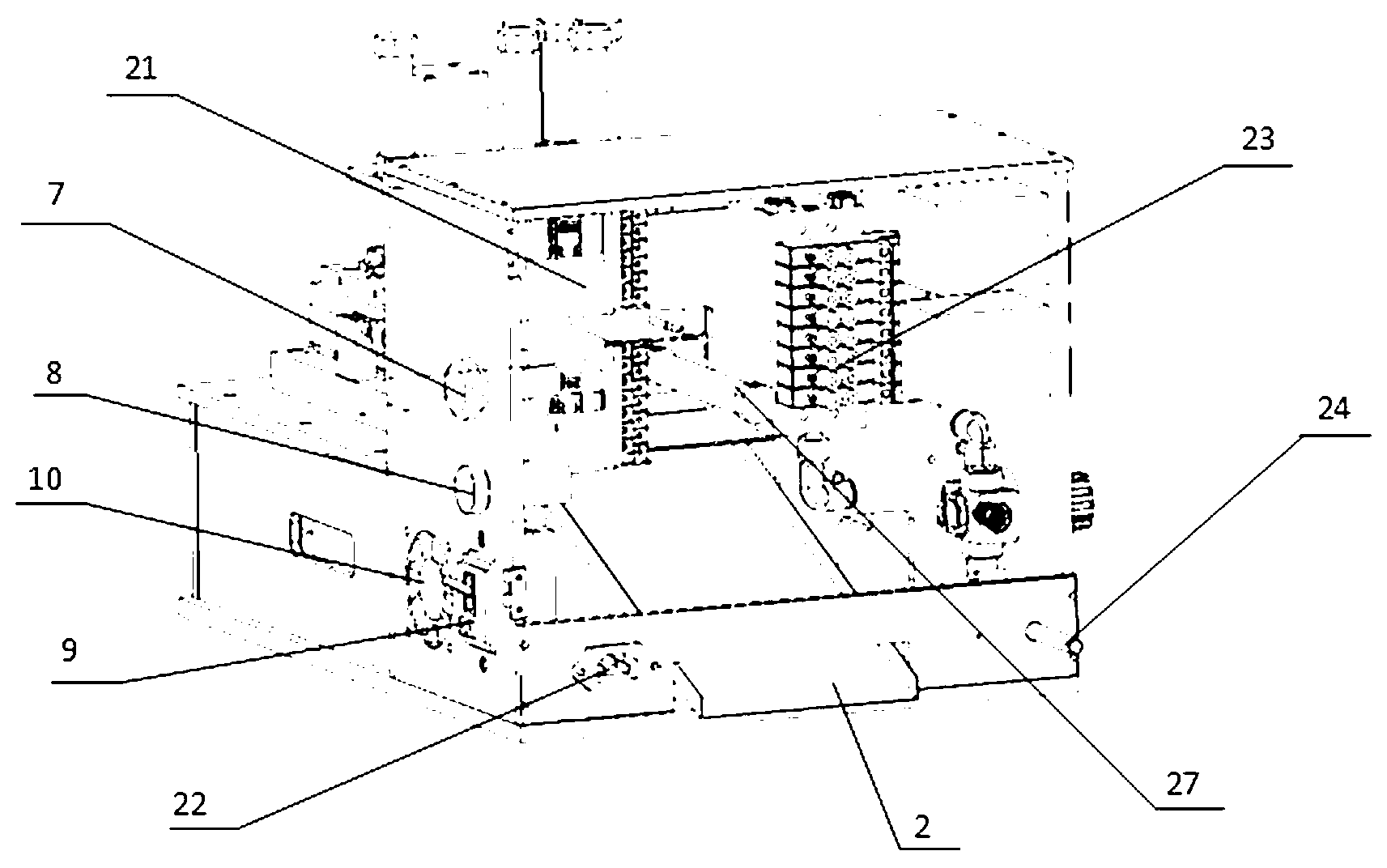

[0025] Such as Figure 1~5 Shown, comprise control box 17, be located at the first start button 6 on the front panel of control box 17, the second start button 33, the first counter 4, the second counter 5, barometer 20 and emergency stop button 19, set The maintenance button 7, indicator light 8, leakage protection switch 9 and cooling fan 10 on the right panel of the control box are set on the temperature controller 11 and air pressure regulating valve 13 on the left panel of the control box, and the power supply on the rear panel of the control box The socket 22 and the air source inlet 24 are arranged on the lower template 14 of the upper panel of the control box. The first linear guide rail 3 and the second linear guide rail 31 are arranged on both sides of the lower template 14. The upper template 16 and the lower template 14 pass through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com