Rotary-arc coupling discharging milling device

A technology of milling processing and arc rotation, which is applied in the field of arc coupling electric discharge milling processing devices, can solve problems such as unstable processing, low processing efficiency, and unclear processing mechanism research, and achieve simple and convenient control operations, improve processing efficiency, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

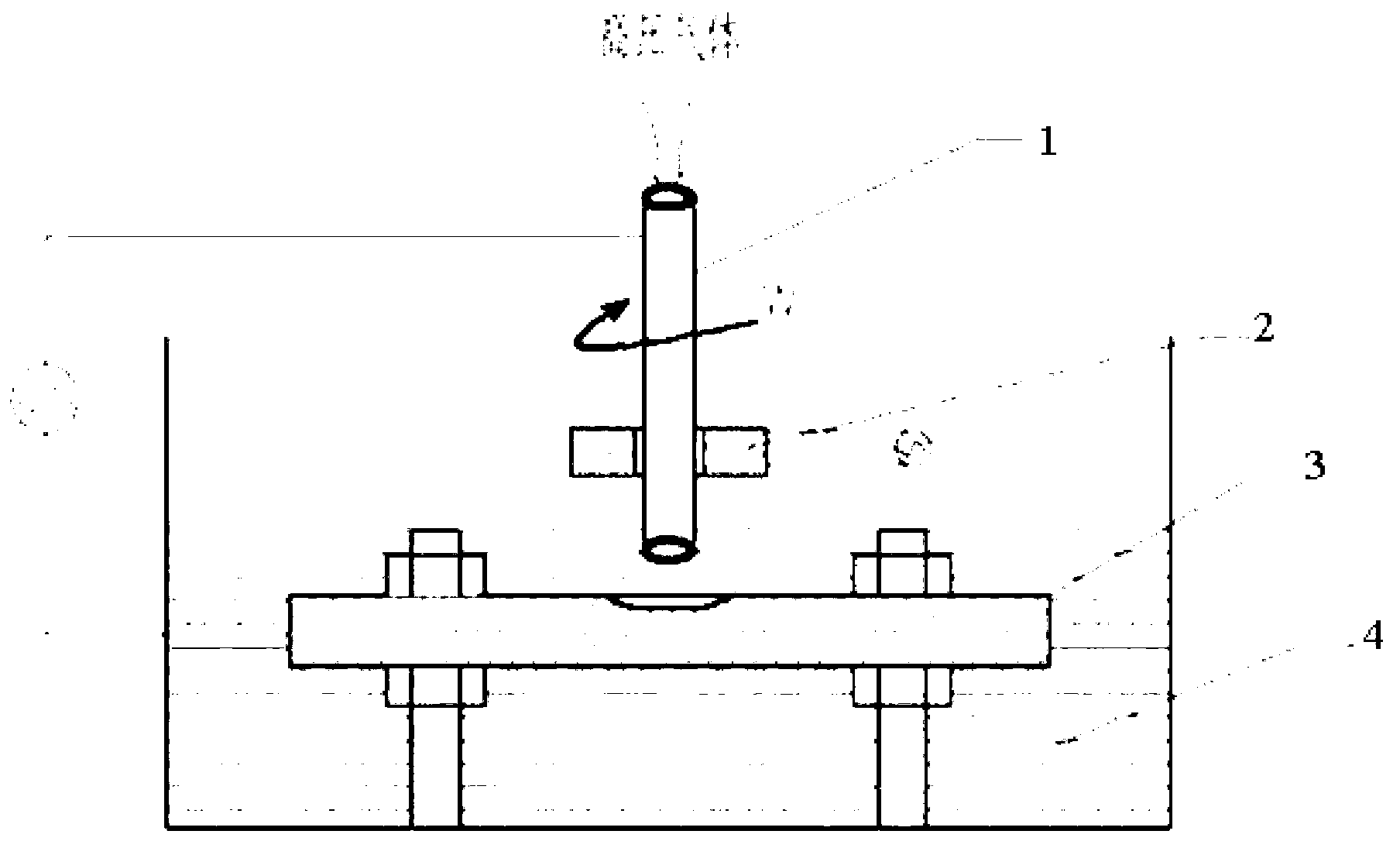

[0019] like figure 1 As shown, a spiral arc coupled electric discharge milling device includes a hollow electrode 1 and an electromagnetic coupling device 2. The hollow electrode 1 applies the theory of electromagnetic discharge erosion to mill a workpiece 3, and the workpiece 3 is placed in a milling fluid 4.

[0020] The processing device mainly uses the magnetic field generated by the electromagnetic coupling device 2 to affect the shape of the arc generated by the hollow electrode 1, thereby generating an arc rotating along the surface of the hollow electrode 1 at high speed to achieve a processing method similar to high-speed milling in machining. According to the principle of electromechanics, for electromagne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com