Roller guide and guard unit for loop

A guide device and guide roller technology, which is applied in the field of steel rolling equipment, can solve problems such as the inability to adjust the distance between guide rollers, and achieve the effects of improving operating efficiency, reducing use costs, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

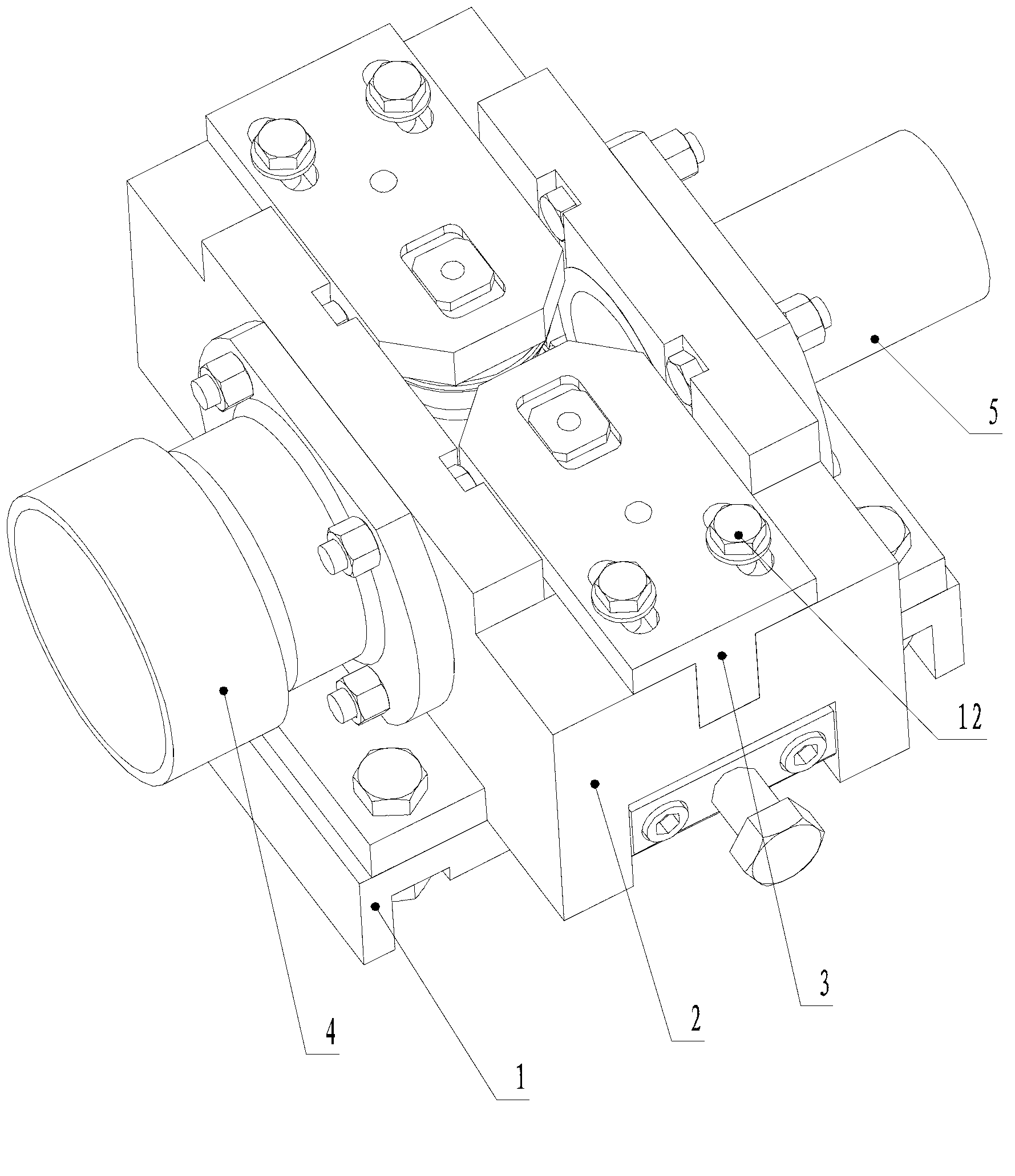

[0012] A rolling guide device for loopers provided in this embodiment has a structure as shown in the figure, including a bracket 1, a jacket 2 is fixed above the bracket by a hexagon head bolt 3, and an inlet conduit 4 is provided on the inlet side of the jacket. An outlet conduit 5 is provided on the outlet side. Wherein, guide roller seats 3 with the same structure are provided on the left and right sides above the jacket, and the two guide roller seats are of adjustable relative distance.

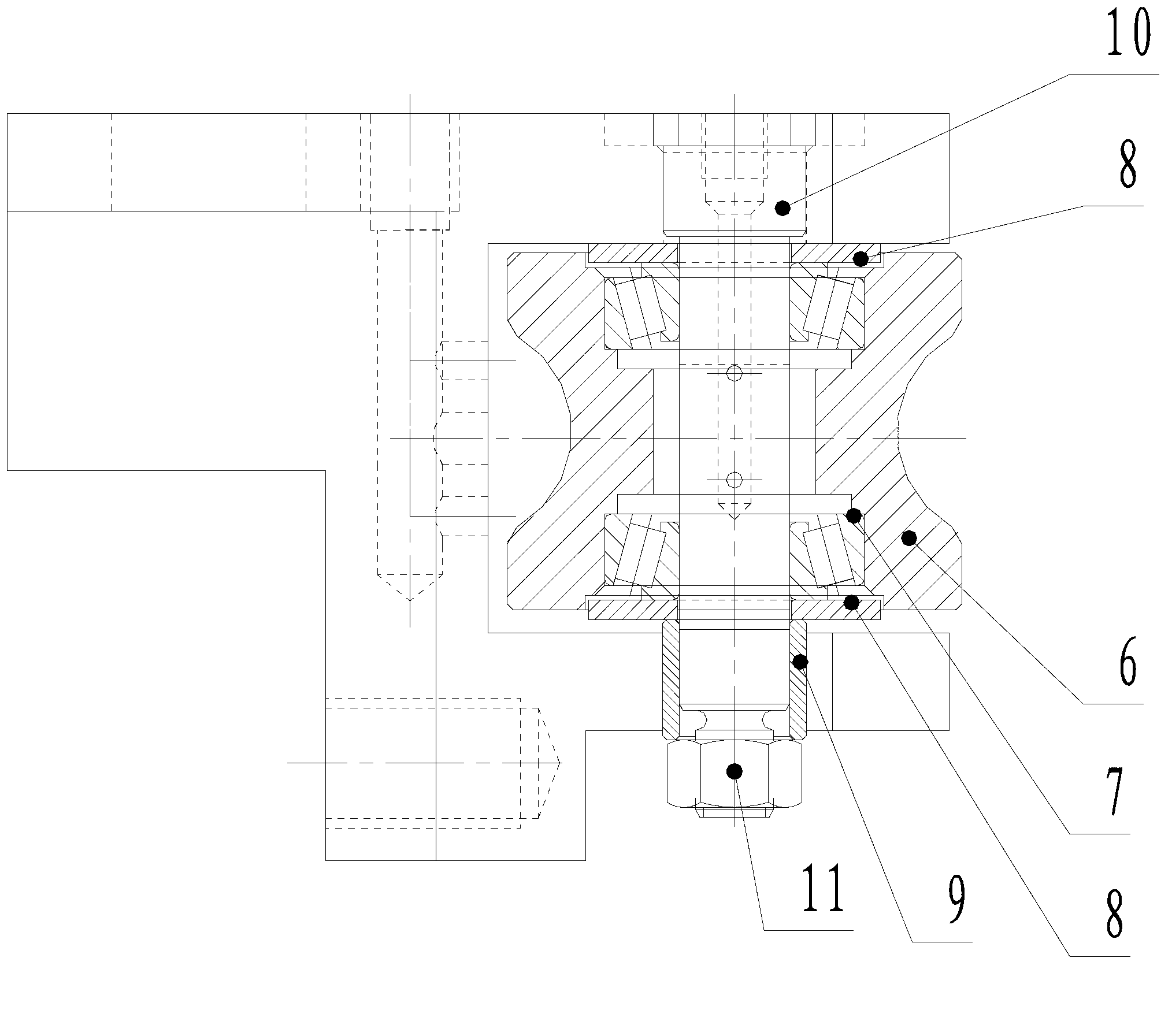

[0013] At the same time, a guide roller 6 is installed in the guide roller seat, and a guide roller shaft 10 runs through the guide roller, and two tapered roller bearings 7 are arranged symmetrically up and down outside the guide roller shaft, and an adjusting gasket 8 is installed outside the tapered roller bearing. , The outer end of the guide roller shaft is sleeved with a copper sleeve 9, and then tightened by a lock nut 11.

[0014] When in use, the guide roller seat is controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com