Harrowing device for collecting and breaking plastic cloth

A technology of harrowing and equipment, applied in the field of cleaning and crushing, can solve the problems of ecological environment soil damage, waste of resources, difficult to degrade, etc., and achieve the effects of reducing pollution, convenient maintenance, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

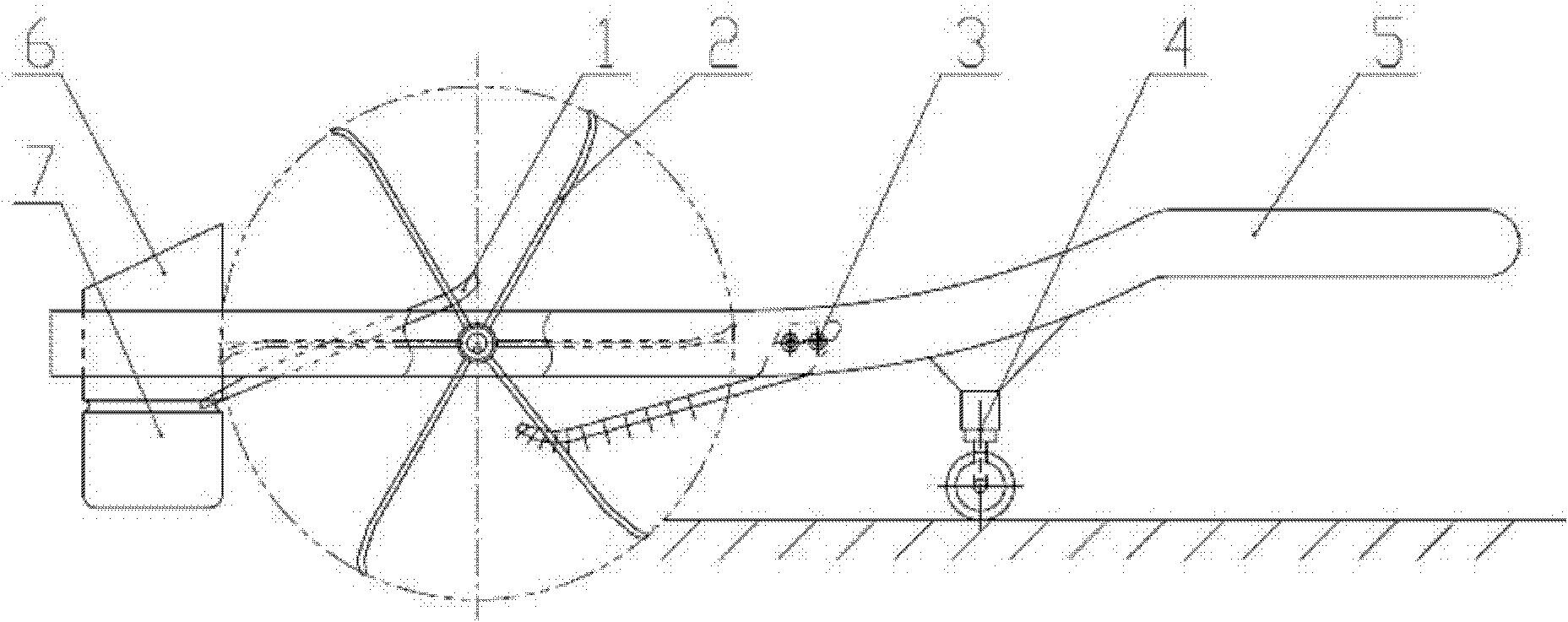

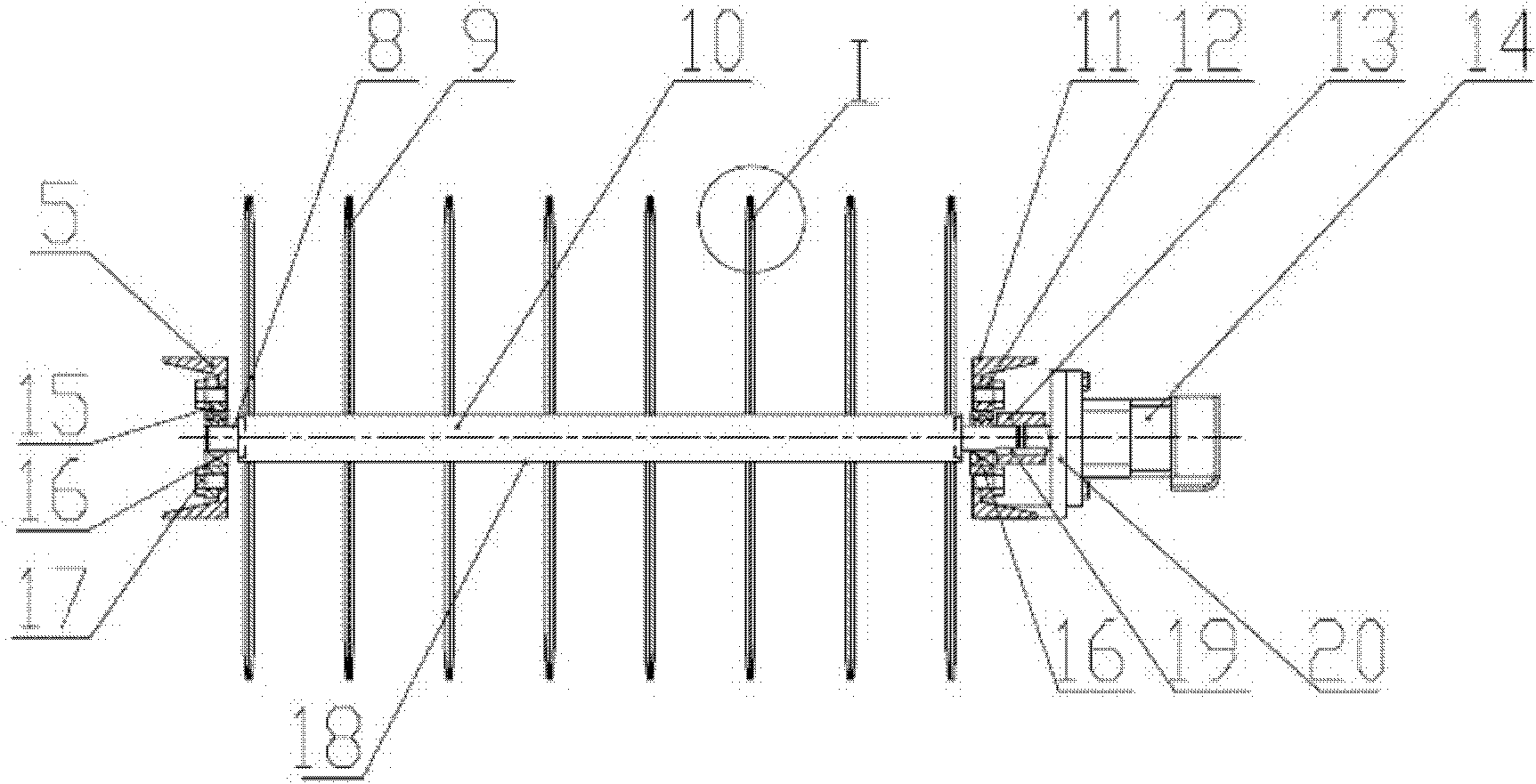

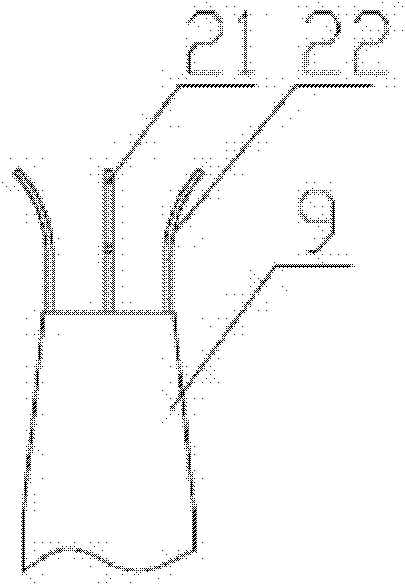

[0043] Figure 1 to Figure 15 It is the plastic cloth collection, crushing and raking equipment described in this embodiment. The equipment includes a material cleaner 3, a material unloader 1 and / or a frame 5, etc., and is characterized in that the plastic cloth collection and crushing and raking equipment also includes a raking material breaker 2, etc. Device 3 and / or unloader 1 etc. are installed on the frame 5. The shaft of the rake breaker 2 is installed on the bearing block I 12 and the bearing block II 15 etc., the bearing block I 12 and the bearing block II 15 etc. are installed on the frame 5, the bearing block I 12 and the bearing block II 15 etc. are installed There are bearings 16 etc., and the shaft body 8 can be rotated. like figure 1As shown, the shaft body 8 rotates under the drive of the driving device, etc., the shaft body 8 drives the rake crushing teeth 9 to insert and turn over the plastic bags, plastic films, plastic sheets, chemical fiber products, kn...

Embodiment 2

[0048] Figure 16 and Figure 17 It is the plastic cloth collecting, crushing and raking equipment described in Example 2. The unloader 1 is composed of a unloading device, a collecting device and a packaging device 43. The unloading device is a plate unloading device. The unloading plate 32 of the plate unloading device is inserted near the axis of the rake breaker 2. The plate unloading device The fixed end of the feeding device is fixed on the frame 5 through the connecting flange. The material collection device is a collection hopper 6 and a collection bag 7. The collection hopper 6 is installed on the frame 5 and plays a role in guiding the materials. effect. Packing device 43 is made up of support 50, oil cylinder fixed seat 44, oil cylinder fixed shaft 45, oil cylinder 46, oil cylinder connecting shaft 47, oil cylinder connecting seat 48 and piston 49 etc. The cylinder block of oil cylinder 46 is connected with oil cylinder holder 44 by oil cylinder fixed shaft 45, ...

Embodiment 3

[0051] Figure 18 and Figure 19 It is the plastic cloth collecting, crushing and raking equipment described in Example 3. like Figure 18 As shown, a safety protection baffle 52 is provided between the rake breaker 2 and the operating mechanism 53 on the frame 5, and the safety protection baffle 52 prevents the materials lifted by the rake breaker 2 from splashing to the operator; like Figure 19 As shown, the operating mechanism 53 of the equipment is arranged in the cab 54, which effectively protects the operator and improves the working environment.

[0052] Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com