Clamping device for large-section expanded diameter conductors

A technology of expanding diameter wire and wire clamp, which is applied in the direction of overhead line/cable equipment, etc., can solve the problems of inability to meet the use requirements of expanding diameter wire, the glue hanging on the surface of the jaws is easy to fall off, and the parallelism of the jaws is poor. High-altitude work, weight reduction, good parallelism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Below in conjunction with example the present invention is described in detail.

[0057] The reasonable bearing capacity system of the lever-type connecting rod mechanism and the optimal contact surface matching technology between the jaw and the expanding wire provide a wire clamp suitable for anchoring the expanding wire and meeting the requirements of construction standards.

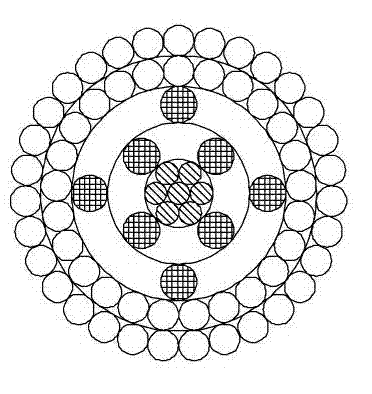

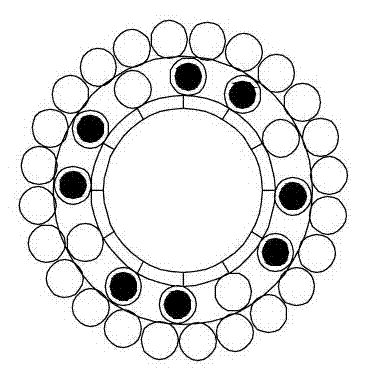

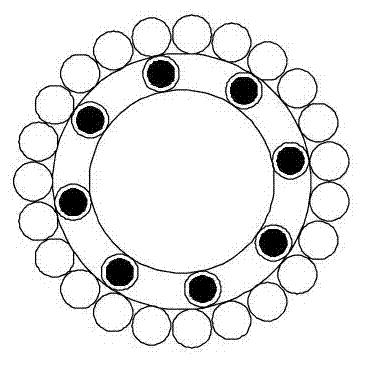

[0058] Figure 1 to Figure 4 It is a schematic cross-sectional view of wires with different diameter-expanding structures applicable to the present invention. figure 1 The inner ring of the expanded diameter wire is all evacuated, the steel core is wrapped with insulating material, and then two layers of aluminum single wire are supported by cross-shaped high-density polyethylene; figure 2 and image 3 The middle layer aluminum wire of the expanded diameter wire is drawn in proportion, the structure is loose, and the force is uneven. Figure 4 Expand the diameter of the wire for another fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com